An automatic drilling machine with adjustable feed rate

An automatic drilling machine and drill bit technology, applied in the direction of boring machine/drilling machine parts, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of reducing efficiency and increasing labor intensity, so as to achieve full automation of the operation process and improve drilling efficiency , the effect of reducing the probability of collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

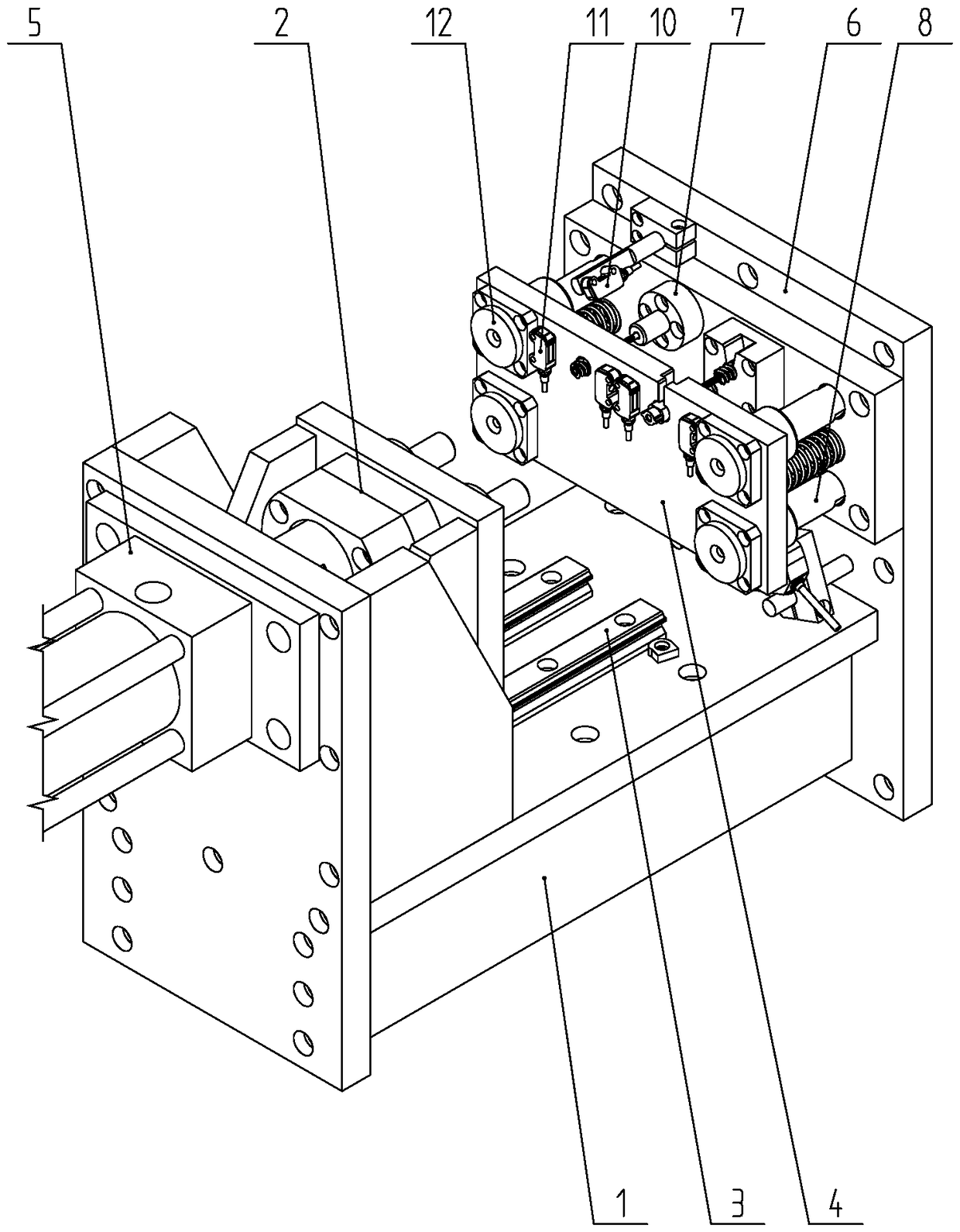

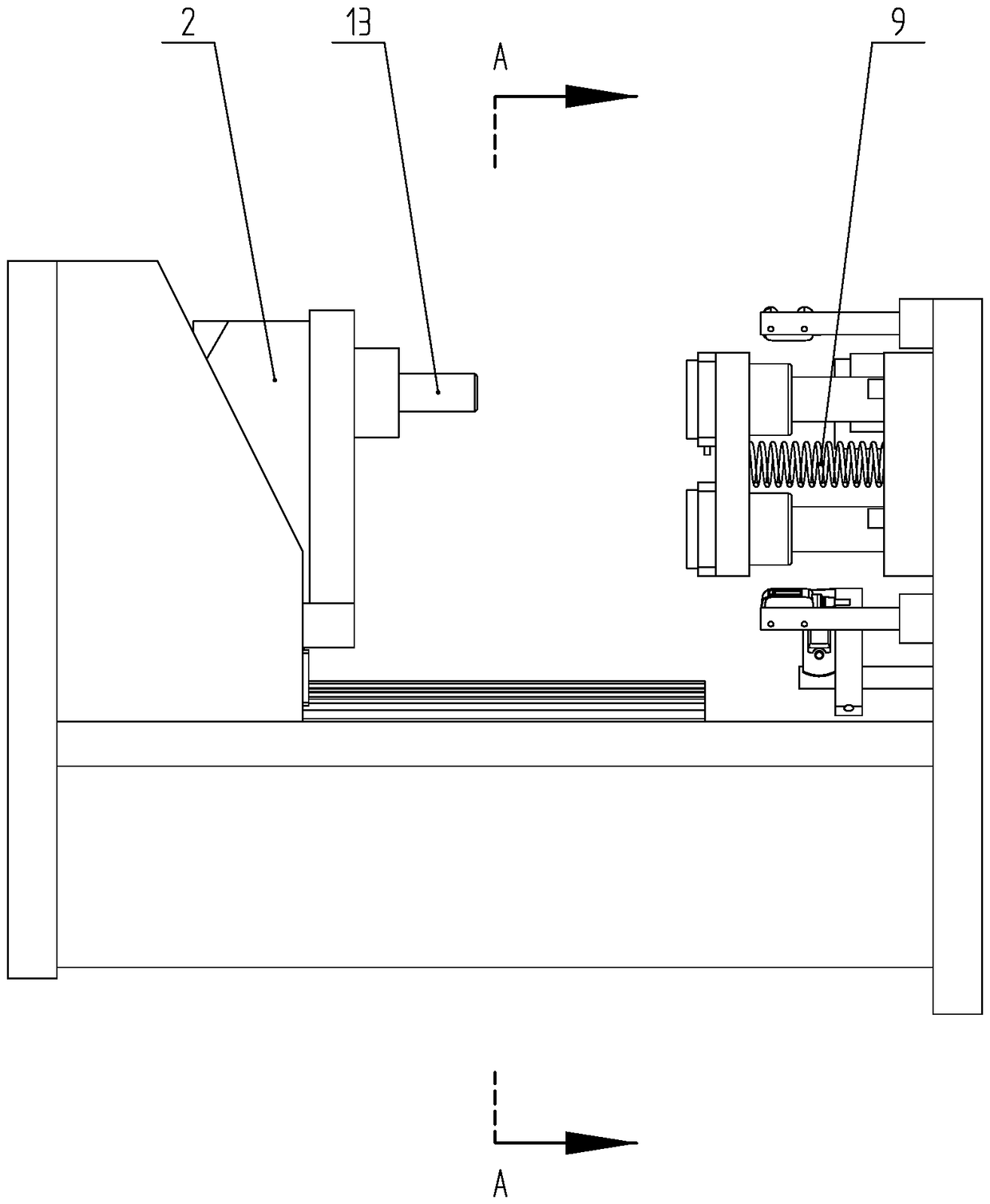

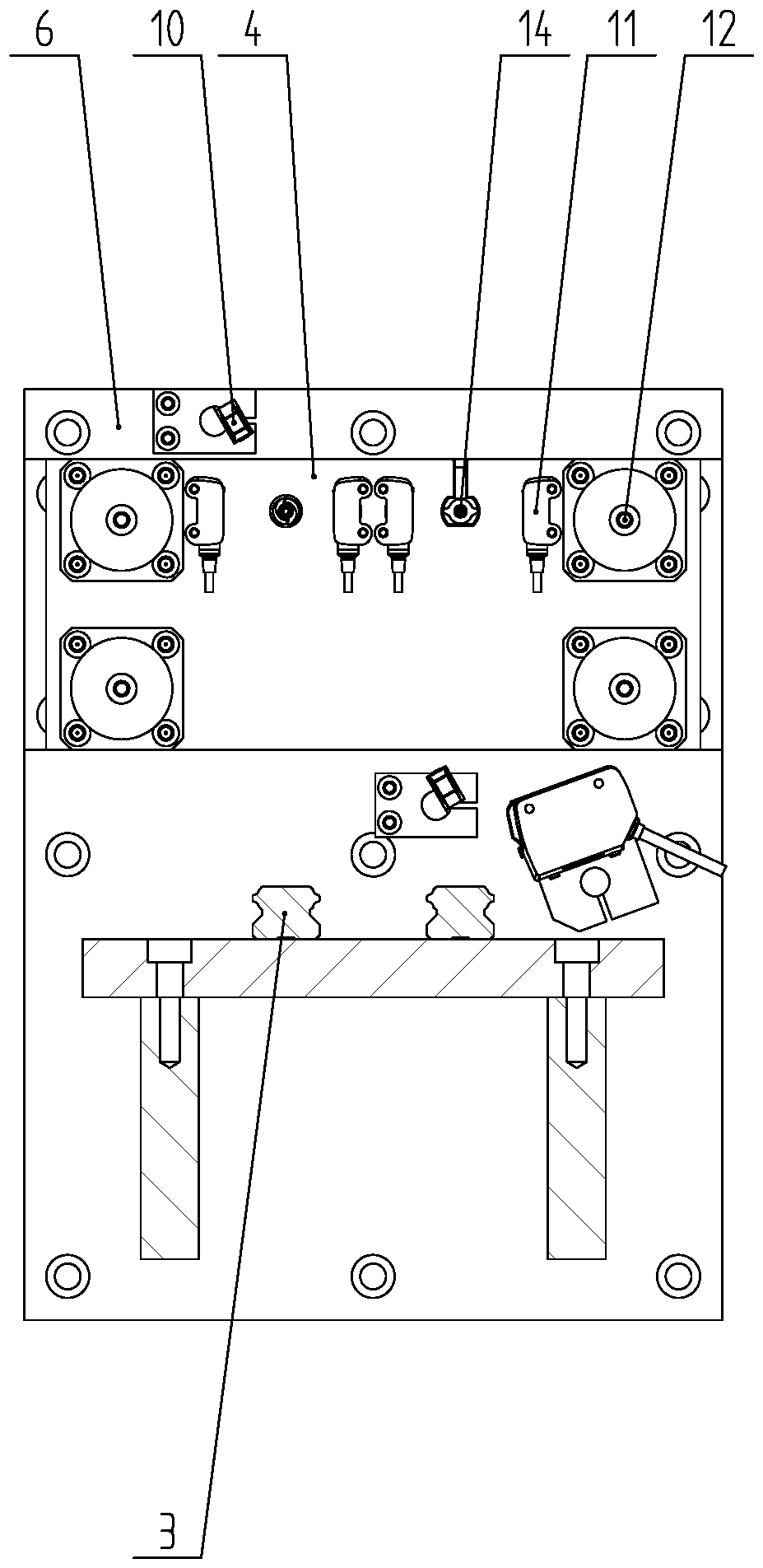

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

[0023] An automatic drilling machine with adjustable feed rate includes a base body 1, a drill bit 14, and a running part 2 and a fixed part 6 installed on the base body 1. The running part 2 is movably installed on the base body 1 through the slide rail 3 , and is driven by the hydraulic cylinder 5 installed on the base body 1 so that it can move linearly along the slide rail 3 . Walking portion 2 is provided with two cross slide rails, and a chuck 13 for clamping workpieces is installed on each cross slide rail, so that the chuck can adjust its position on the running portion so as to drill holes in different positions. The fixed portion 6 is provided with a rotary drill holder 7 coaxial with the chuck 13, the number of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com