Electric knapsack sprayer

A knapsack and sprayer technology, applied in the field of sprayers and electric knapsack sprayers, can solve the problems of cumbersome stirring operation process, easy precipitation of chemicals, affecting spraying uniformity, etc., to improve work efficiency, prevent clogging, and achieve uniformity of chemicals. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

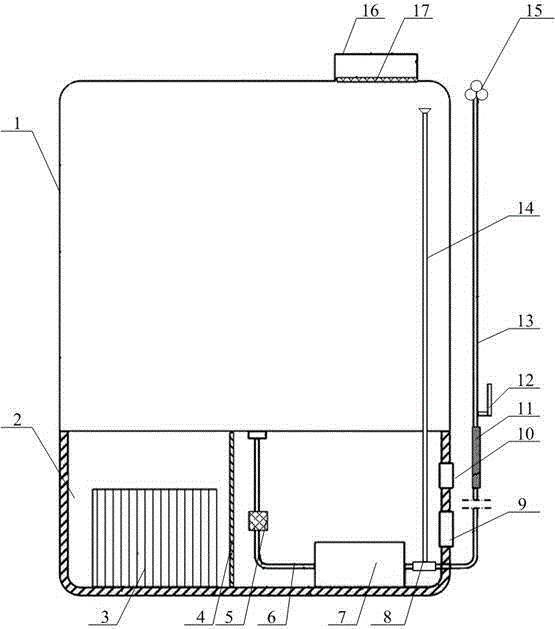

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the electric knapsack sprayer of the present invention includes a medicament storage box 1 and a spray device box 2 . The medicament storage box 1 is provided with a liquid inlet, the liquid inlet is provided with a case cover 16, and the case cover 4 is provided with a filter screen 17; the spray device case 2 is provided with a diaphragm pump 7, an electric reversing valve 8 and a storage battery 3, Accumulator 3 is movably installed in the spray device box 2, so that it can be replaced in time when the power supply is insufficient, and the working efficiency of the sprayer is improved. A sealing plate 4 is arranged between the diaphragm pump 7, the electric reversing valve 8 and the storage battery 3, and the sealing plate 4 isolates the diaphragm pump 7, the electric reversing valve 8 and the storage battery 3 to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com