A Cross Micromixer with Symmetrical Elliptical Arc Baffles

A technology of micro-mixer and arc baffle, which is applied in the direction of mixers, mixing methods, chemical instruments and methods, etc., can solve the problems of small Reynolds number of liquids, prolonged mixing time, poor mixing effect, etc., and achieve improved mixing effect and increased Reynolds number, the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

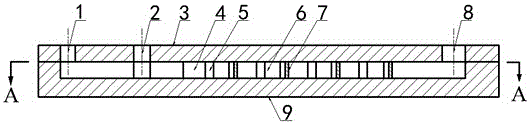

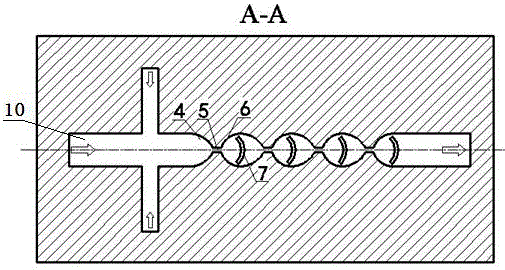

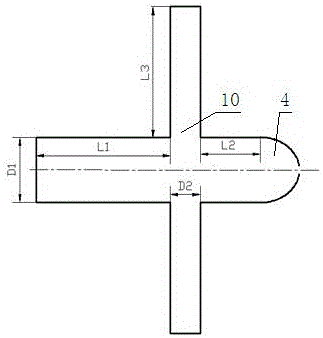

[0019] Such as figure 1 , 2 As shown, the main structure of the present invention is divided into upper and lower parts, the upper side is the cover plate 3 of the micro-mixer, and the lower side is the base body 9, and the cover plate 3 and the base body 9 are close together up and down. The flow channel of the micromixer is arranged between the cover plate 3 and the base body 9 . The flow channel is composed of a cross-shaped flow channel 10 , a constricted flow channel 4 , a plurality of narrow straight channels 5 and a plurality of elliptical flow channels 6 . Three runner inlets are arranged on the cross-shaped runner 10, which are respectively a main runner inlet 1 and two auxiliary runner inlets 2, and the main runner and the auxiliary runner intersect vertically in a cross shape. The outlet of the cross-shaped flow channel 10 is arranged on its main flow channel, and the center of the main flow channel is located on the central axis.

[0020] The outlet of the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com