Wheel-type wide-width precision seeding device

A wide and precise technology, applied in the field of axle-type wide-width precision seed cloth device, can solve problems such as affecting sowing accuracy, deviation from sowing point, seed bounce, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

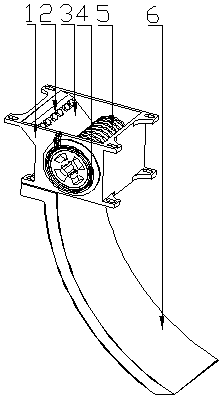

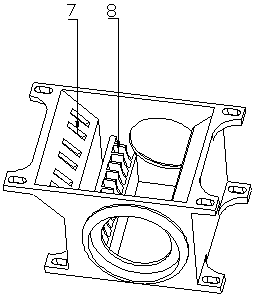

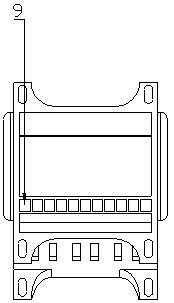

[0026] as attached figure 1 to attach Figure 7 As shown, the embodiment of the present invention provides a wheel-type wide-width precision seed distribution device, including a seed meter and a seed distribution pipe 6. The seed meter includes a box body 1, an inner core 5 and a seed outlet 9. The inner The core 5 is cylindrical, the inner core 5 is located inside the box 1, and the two ends of the inner core 5 are connected to the box 1 through bearings 4, and the outer surface of the inner core 5 is provided with evenly distributed The hollow dimples 10 are distributed in a row of five and a row of six intervals. The interior of the box 1 is provided with a row of brushes 3 along the axial direction of the inner core 5. The brushes 3 and the box 1 The inner wall is threaded, the seed discharge port 9 is located at the bottom of the box body 1, the seed distribution pipe 6 is located below the seed meter, the seed distribution pipe 6 includes a seed trough 12, and the seed...

Embodiment 2

[0033] as attached figure 1 To attach Figure 7 As shown, the embodiment of the present invention provides a wheel-type wide-width precision seed distribution device, including a seed meter and a seed distribution pipe 6. The seed meter includes a box body 1, an inner core 5 and a seed outlet 9. The inner The core 5 is cylindrical, the inner core 5 is located inside the box 1, and the two ends of the inner core 5 are connected to the box 1 through bearings 4, and the outer surface of the inner core 5 is provided with evenly distributed The hollow dimples 10 are distributed in a row of five and a row of six intervals. The interior of the box 1 is provided with a row of brushes 3 along the axial direction of the inner core 5. The brushes 3 and the box 1 The inner wall is threaded, the seed discharge port 9 is located at the bottom of the box body 1, the seed distribution pipe 6 is located below the seed meter, the seed distribution pipe 6 includes a seed trough 12, and the seed...

Embodiment 3

[0038] as attached figure 1 To attach Figure 7 As shown, the embodiment of the present invention provides a wheel-type wide-width precision seed distribution device, including a seed meter and a seed distribution pipe 6. The seed meter includes a box body 1, an inner core 5 and a seed outlet 9. The inner The core 5 is cylindrical, the inner core 5 is located inside the box 1, and the two ends of the inner core 5 are connected to the box 1 through bearings 4, and the outer surface of the inner core 5 is provided with evenly distributed The hollow dimples 10 are distributed in a row of five and a row of six intervals. The interior of the box 1 is provided with a row of brushes 3 along the axial direction of the inner core 5. The brushes 3 and the box 1 The inner wall is threaded, the seed discharge port 9 is located at the bottom of the box body 1, the seed distribution pipe 6 is located below the seed meter, the seed distribution pipe 6 includes a seed trough 12, and the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com