A high-speed train axle aging analysis method based on axle temperature data

An aging analysis, high-speed train technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of time-consuming and low-accuracy detection of axle faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

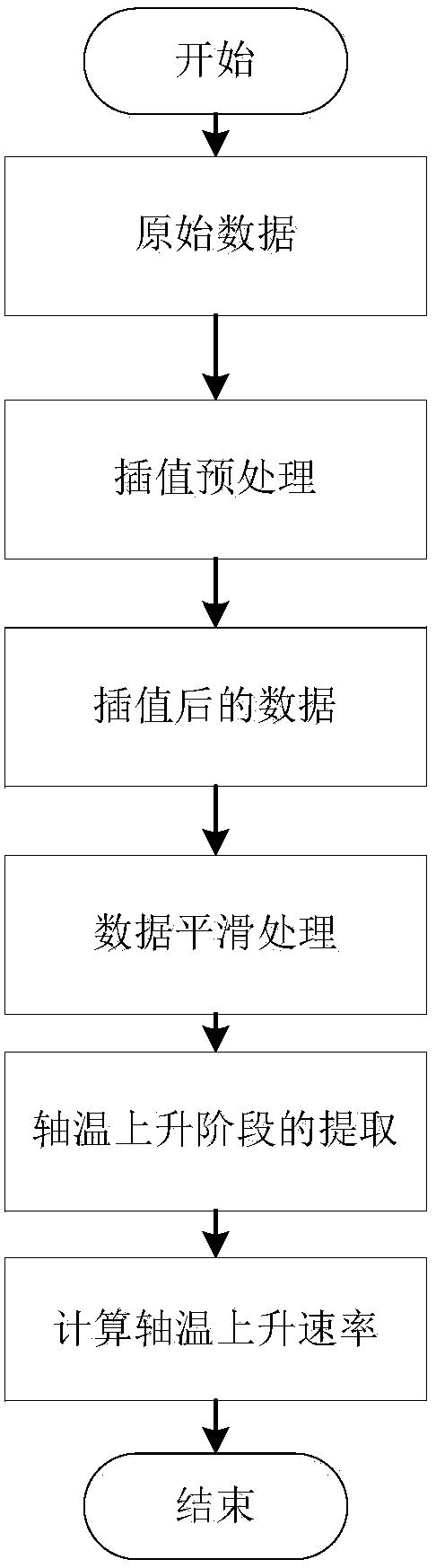

[0120] A high-speed train axle aging analysis method based on axle temperature data of the present invention is specifically implemented according to the following steps:

[0121] Step 1. Preprocessing the train speed and axle temperature data:

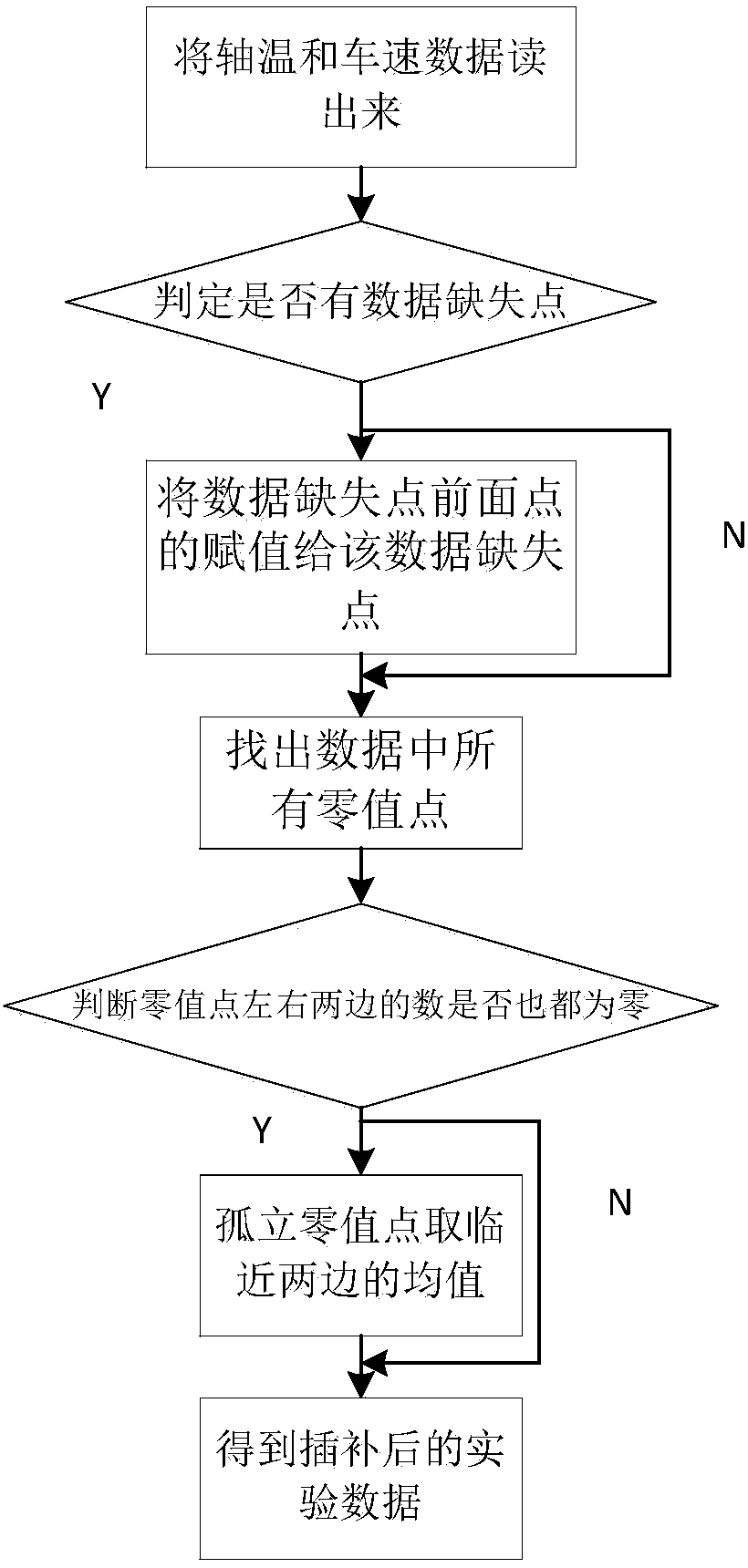

[0122] Step (1.1), supplement of data missing points:

[0123] Collect train speed spe(i) and shaft temperature zw(i), where i is the corresponding sampling time point, i=20, as shown in Table 1 and Table 2, draw a schematic diagram of the initial shaft temperature signal curve,

[0124] Table 1: Sampling data of shaft temperature zw(i)

[0125] sampling time point

1

2

3

4

5

6

7

8

Shaft temperature

28.67249

30.28081

30.28081

30.28081

31.88913

31.88913

0

sampling time point

9

10

11

12

13

14

15

16

Shaft temperature

33.49745

35.10577

35.10577

36.71409

36.71409

36.71409

38.32241

38.32241

sampling time poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com