Test strip insert for detection cup, manufacturing method and detection device

A manufacturing method and technology for test strips, which are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reactions of materials, etc., can solve the problem that the test strip cannot be fixed in a predetermined position, etc. The effect of improving precision and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

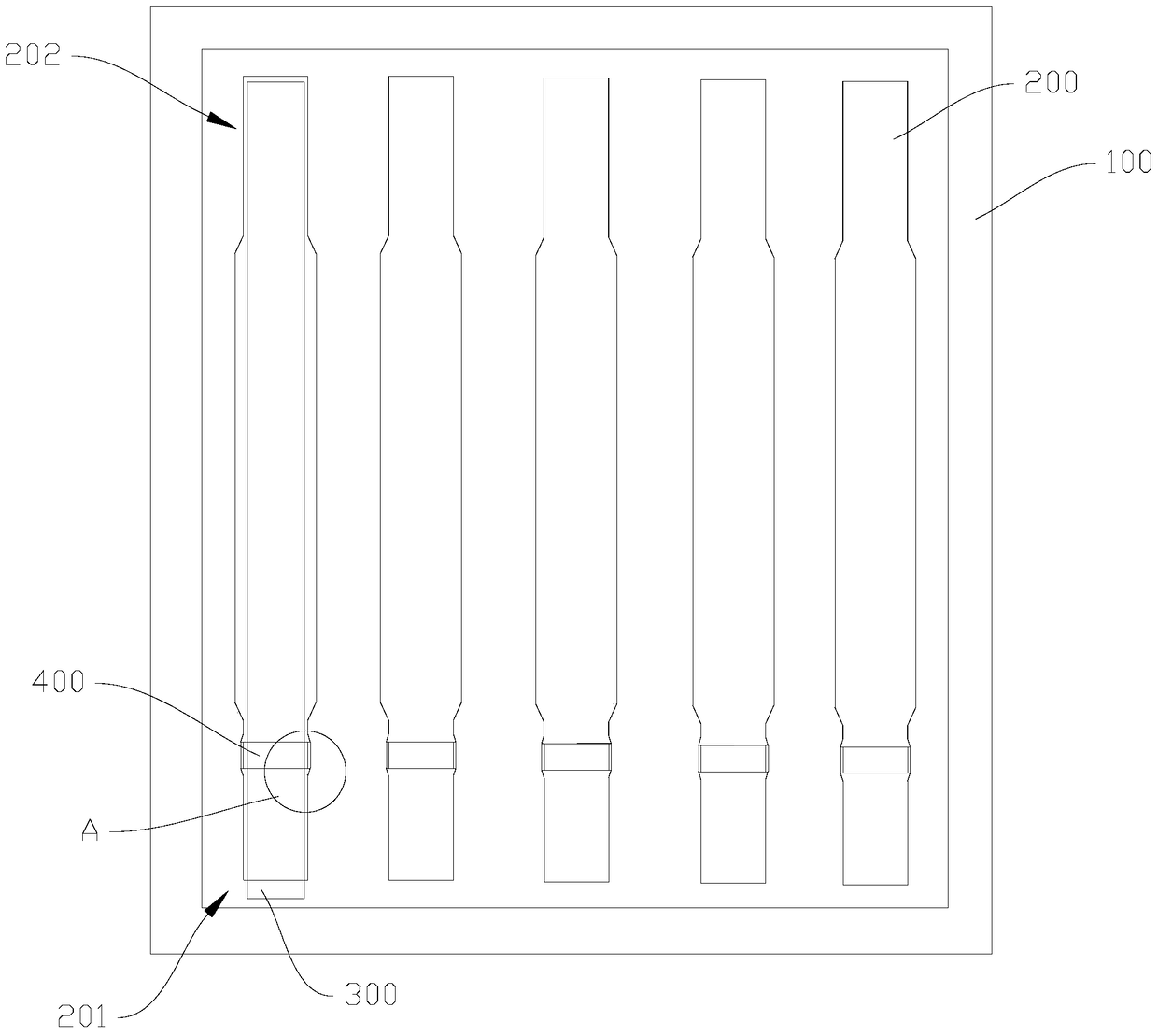

[0029] A test strip insert for testing cups, such as Figure 1-4 As shown, it includes a negative sheet 100 and at least one test paper insert 200 attached to one or both sides of the negative sheet 100; the negative sheet 100 is a larger sheet, usually made of plastic material that cannot absorb liquid, or other The sheet should have a certain degree of elasticity and rigidity, so as to ensure that the test paper insert can be placed upright in the test cup, and the large-area negative film 100 can prevent the detection liquid from splashing on the surface of the test paper insert 200 to affect the color development of observation. Effect. The test paper insert 200 is usually located in the direction of the negative film 100 towards the outside of the detection cup, but the test paper insert 200 can also be arranged on the inner side of the negative film 100, and at this time the color development effect may be blocked by the liquid adhered to the surface of the test paper in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com