Single component silk-screen insulating ink for cupronickel shielding cover insulating film of electronic product

A technology of electronic products and insulating ink, which is applied in the field of one-component screen printing insulating ink, can solve the problems of low construction efficiency, achieve the effects of improving construction efficiency, improving stamping processability, and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

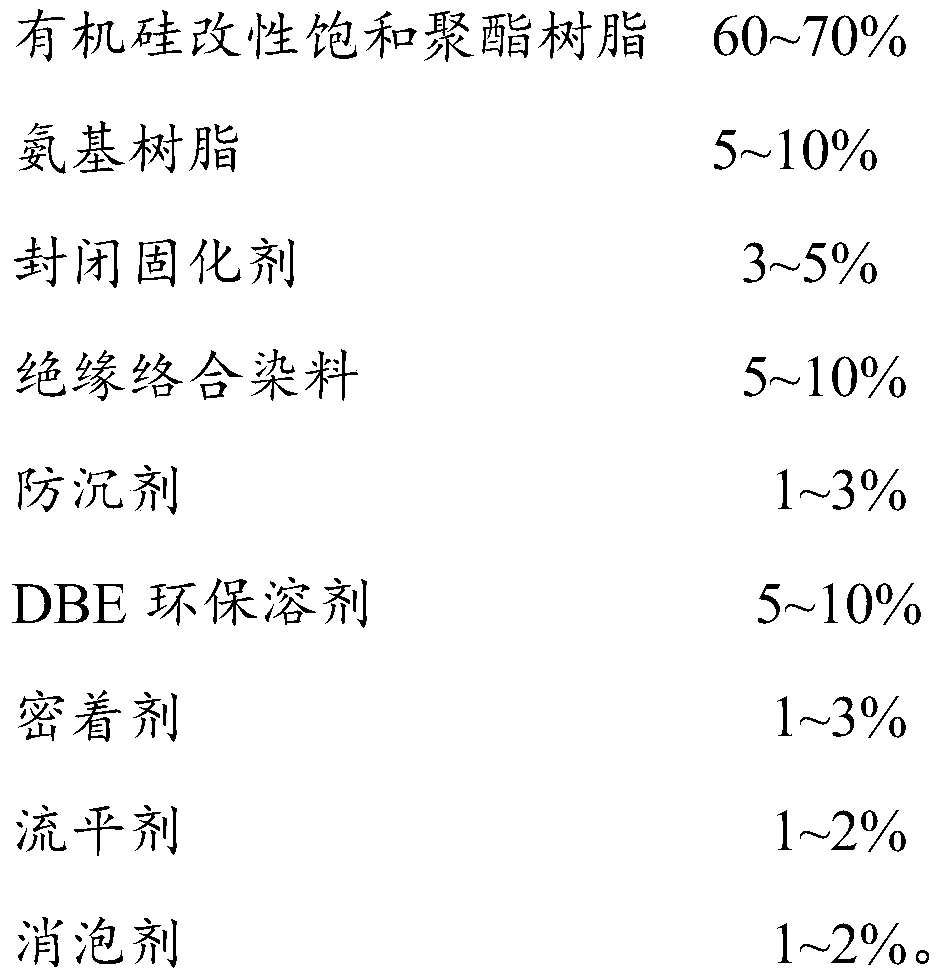

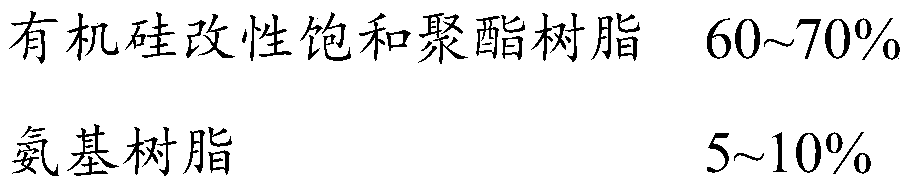

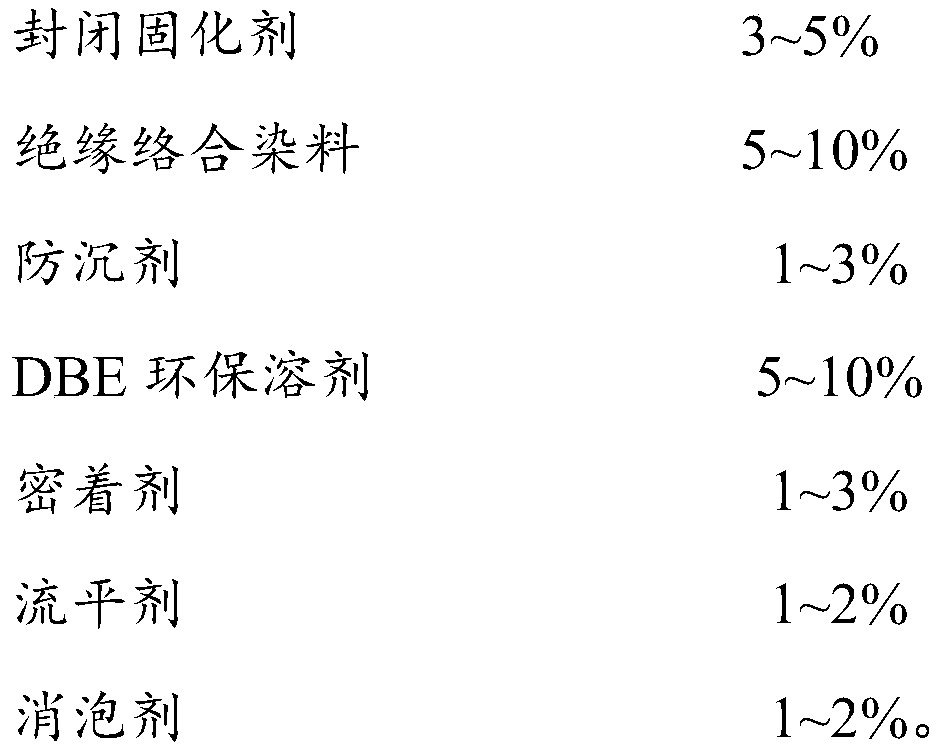

[0038] A preparation method of a single-component screen printing insulating ink used for the insulating film of the white copper shielding cover of electronic products includes the following steps:

[0039] (1) Add the silicone-modified saturated polyester resin and add anti-settling agent at a stirring speed of 800-1000 rpm, then increase the speed to 1600-1800 rpm, and stir for 20-40 minutes until dispersed Evenly, after cooling to room temperature, use a three-roll machine to grind to a fineness of ≤10um to obtain a semi-finished product;

[0040] (2) Add insulating complex dyes, amino resins, sealing curing agents, adhesion agents, leveling agents, and defoaming agents to the semi-finished products, and then mix them evenly, at a stirring speed of 800-1000 rpm, stirring for 5-15 minute;

[0041] (3) Add DBE environmentally friendly solvent, control the stirring speed to 800-1000 rpm, stir for 5-15 minutes, adjust the viscosity to 5000-8000mpa.s / 25℃, mix well and filter with a f...

Embodiment 1

[0042] Example 1 (Take the manufacture of 100KG a single-component insulating screen printing ink used for the printing of white copper shields of electronic products as an example):

[0043] (1) Add 60KG of organic silicon modified saturated polyester resin into the mixing tank, add 3KG of fumed silica at a speed of 800 rpm, then increase the speed to 1600 rpm, and stir for 50 minutes to Disperse uniformly, after cooling to room temperature, grind on a three-roller machine to a fineness of ≤10um to obtain semi-finished products;

[0044] (2) Add 10 kg of insulating golden complex dye, 5 kg of methyl etherified amino resin, 5 kg of sealing curing agent, 3 kg of phosphate adhesive, 2 kg of silicone leveling agent, and 2 kg of silicone defoamer to the semi-finished product , Mix evenly, the stirring speed is 800 rpm, stirring for 15 minutes;

[0045] (3) Add 10KG of DBE environmentally friendly solvent, control the stirring speed to 800 rpm, stir for 15 minutes, adjust the viscosity t...

Embodiment 2

[0046] Example 2 (to make 100KG a single-component insulating black screen printing ink for the white copper shielding cover of electronic products):

[0047] (1) Add 70KG of organic silicon-modified saturated polyester resin into the mixing tank, add 1KG of fumed silica at a stirring speed of 900 rpm, then increase the speed to 1700 rpm, and stir for 40 minutes to Disperse uniformly, after cooling to room temperature, grind on a three-roller machine to a fineness of ≤10um to obtain semi-finished products;

[0048] (2) Add 6KG of insulating black complex dye and 10KG of methyl etherified amino resin, 4 kg of sealing curing agent, 1.5KG of phosphate adhesive, 1.5KG of silicone leveling agent, and silicone defoamer into the semi-finished product 1KG, mix evenly, the stirring speed is 900 rpm, stirring for 10 minutes;

[0049] (3) Add 5KG of DBE environmentally friendly solvent, control the stirring speed to 900 rpm, stir for 10 minutes, adjust the viscosity to 5000~8000mpa.s, mix well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com