Spiral cutter ice-cutting snowmaking equipment

A helical knife and snow making technology, applied in lighting and heating equipment, ice making, leisure ice making, etc., can solve the problems of high maintenance cost, high investment cost and high technical content, and achieve low maintenance cost and equipment structure. Simple, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

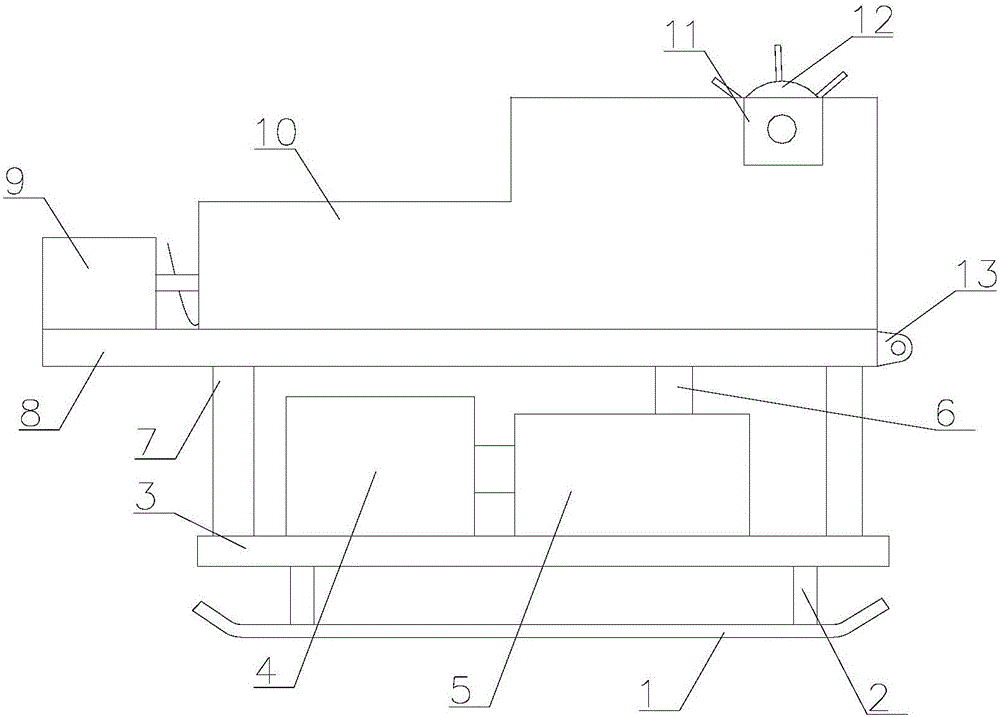

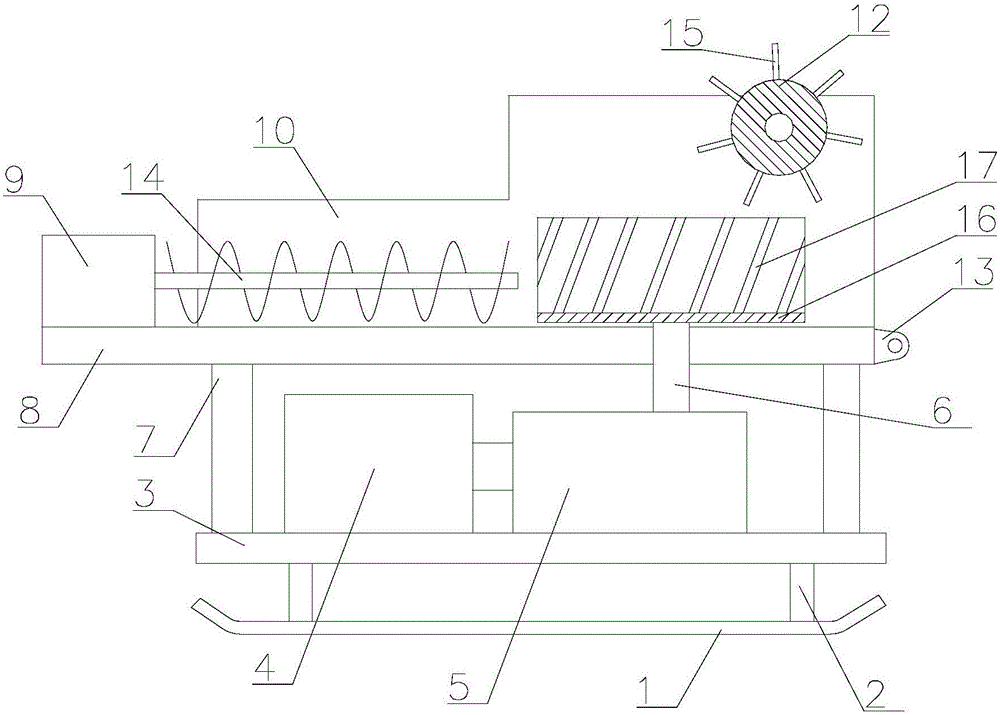

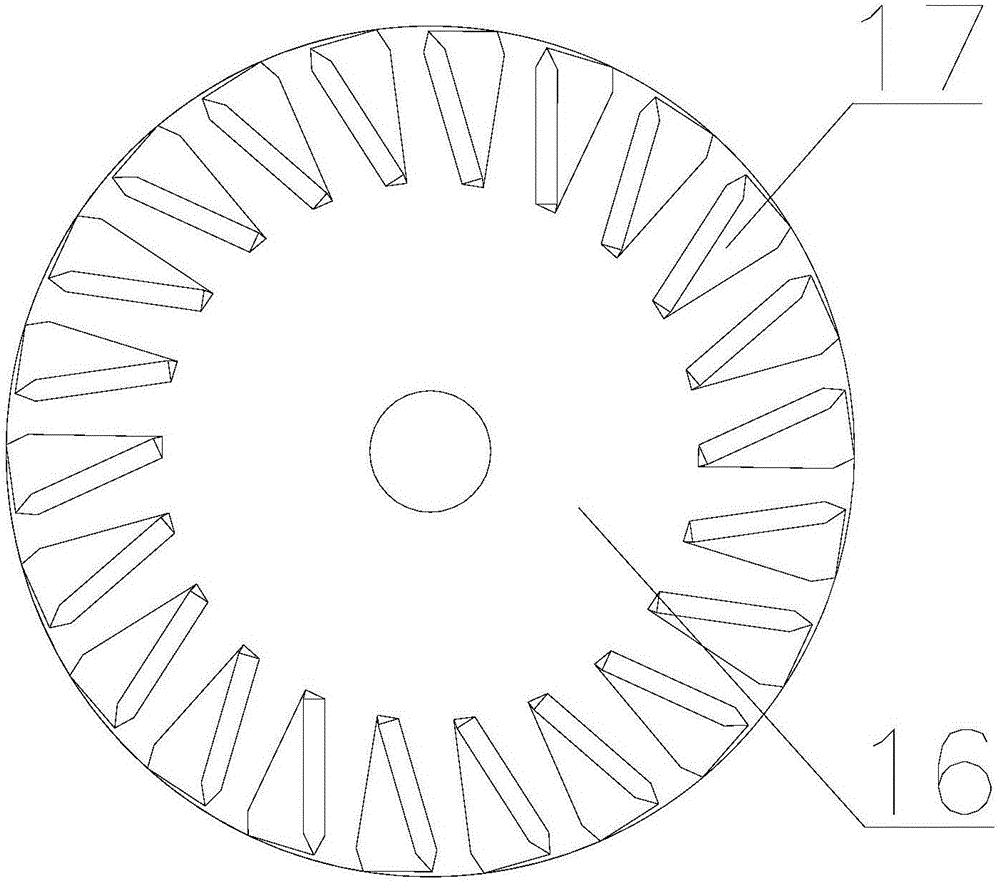

[0017] refer to figure 1 , figure 2 and image 3 , a spiral cutter ice-cutting snowmaking equipment according to the present invention, comprising a sled board 1, a connecting rod 2, a lower base plate 3, a cutting motor 4, a gearbox 5, a transmission shaft 6, a support rod 7, an upper base plate 8, and a feeding motor 9 , guard plate 10, discharge motor 11, discharge roller 12, traction seat 13, feed screw 14, discharge plate 15, turntable 16 and spiral cutter 17, described sled board 1 is connected with lower base plate 3 by connecting rod 2 Fixedly connected, the lower bottom plate 3 is equipped with a cutting motor 4 and a gearbox 5, the cutting motor 4 and the gearbox 5 are connected through a main shaft, the gearbox 5 is provided with a transmission shaft 6, and the upper part of the transmission shaft 6 A turntable 16 is provided, and 10-30 spiral cutters 17 are arranged on the upper part of the turntable 16. The blades of the spiral cutters 17 are in a spiral shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com