Boiler distributor not prone to burning-out

A material distributor and boiler technology, which is applied in the combustion method, combustion equipment, fuel supply and other directions, can solve the problems of the pipe wall of the distributor being burned out, affecting the appearance, and the paint peeling of the distributor, so as to prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

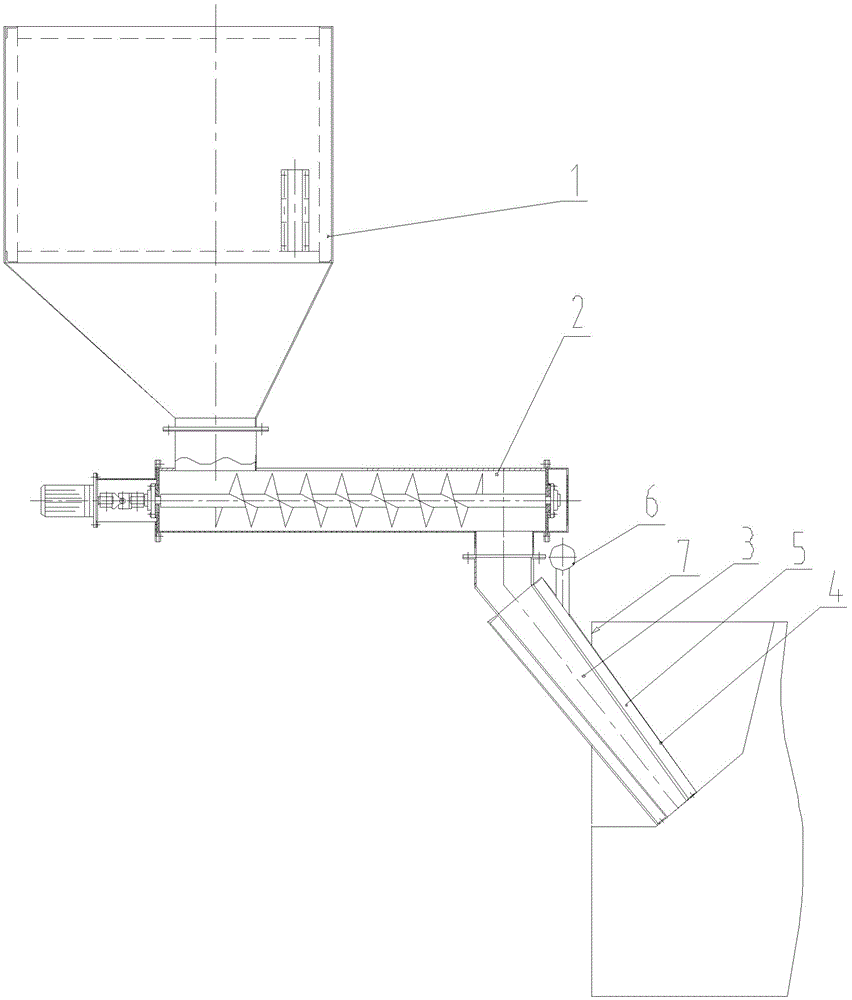

[0011] figure 1 The biomass boiler feeding system shown includes a hopper 1, a screw feeder 2, and a feeder 3, and the feed inlet at the upper end of the feeder 3 is connected to the discharge port of the screw feeder 2, and the The discharge opening at the lower end of the distributor 3 is located above the fire grate of the boiler, and the outer circumference of the distributor 3 is surrounded by a protective cover 4, and a cavity 5 is formed between the protective cover 4 and the distributor 3. The protective cover 4 is provided with a cooling fan pipe seat 6 for connecting the cooling fan; the inner surfaces of the upper and lower ends of the protective cover 4 are welded with multiple pieces of angle steel (not shown in the figure), and the angle steel and the distributor 3 in contact with the outer peripheral surface, the lower end of the protective cover 4 is welded on the front panel 7 of the boiler through angle steel, and the lower end of the protective cover 4 can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com