Light double-node pipeline J-shaped laying system

A dual-node, pipeline technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as pipeline damage, complicated transmission of pipe sections, and small angle range, so as to ensure smooth progress and increase The effect of laying efficiency and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

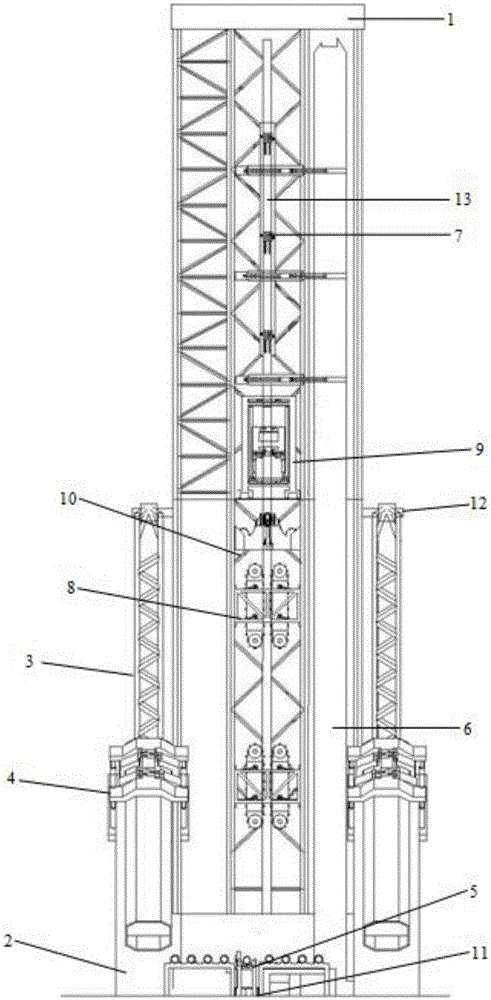

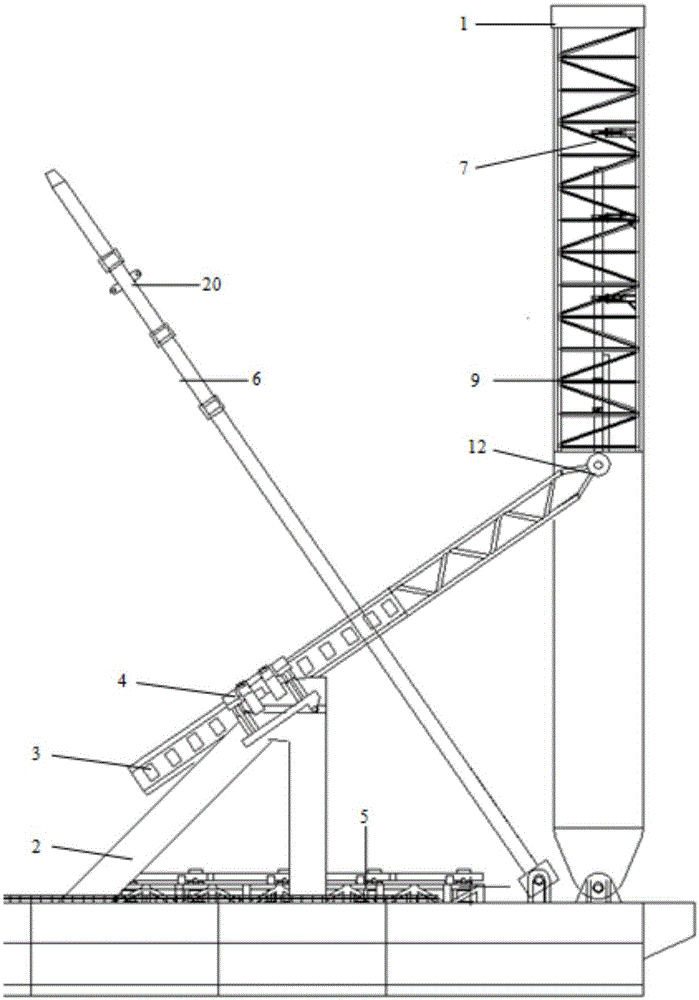

[0028] The invention comprises a J-shaped tower, an angle adjustment part of the J-shaped tower, a pipeline transmission part and a pipeline laying part. The J-type tower is the core part of the entire pipe-laying system, which is used to support, fix and connect other structures and key equipment of the J-type laying; the angle adjustment part of the J-type tower includes an angle adjuster, an A-frame and a hydraulic cylinder, which are connected to the Between the hull and the J-shaped tower, the free adjustment of the J-shaped tower within a certain angle range can be realized; the pipeline transmission part includes a horizontal transmission system, a loading arm, a rotating arm and a vertical roller, which are used for pipe sections to be transported between the pipe-laying ship and the J-shaped tower. Transmission on the tower; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com