Bridge swivel structure

A swivel, bridge technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

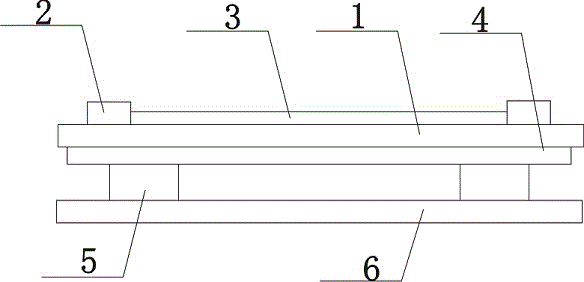

[0013] The present invention will now be described in further detail in conjunction with the accompanying drawings, which are simplified schematic diagrams, only schematically illustrating the basic structure of the present invention, and therefore only show the configurations related to the present invention.

[0014] Such as figure 1 The preferred embodiment of the shown bridge swivel structure of the present invention includes a stainless steel slide plate 1, the upper surface of the stainless steel slide plate 1 is provided with an adapter plate 2 near the two sides, and the bottom of the adapter plate 2 is flexibly connected to the stainless steel slide plate 1. A stopper 3 is installed between the two adapter plates 2, both ends of the stopper 3 extend inside the adapter plate 2, the lower surface of the stainless steel slide 1 is connected with a guard plate 4, and the guard plate 4 and the stainless steel slide 1 pass through a built-in chute connection, the lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com