Electroplating equipment

A technology of electroplating equipment and electroplating tank, which is applied in the direction of electrolysis process, electrolysis components, etc., can solve problems such as affecting the quality of the coating layer, and achieve the effects of low input cost, convenient continuous production, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

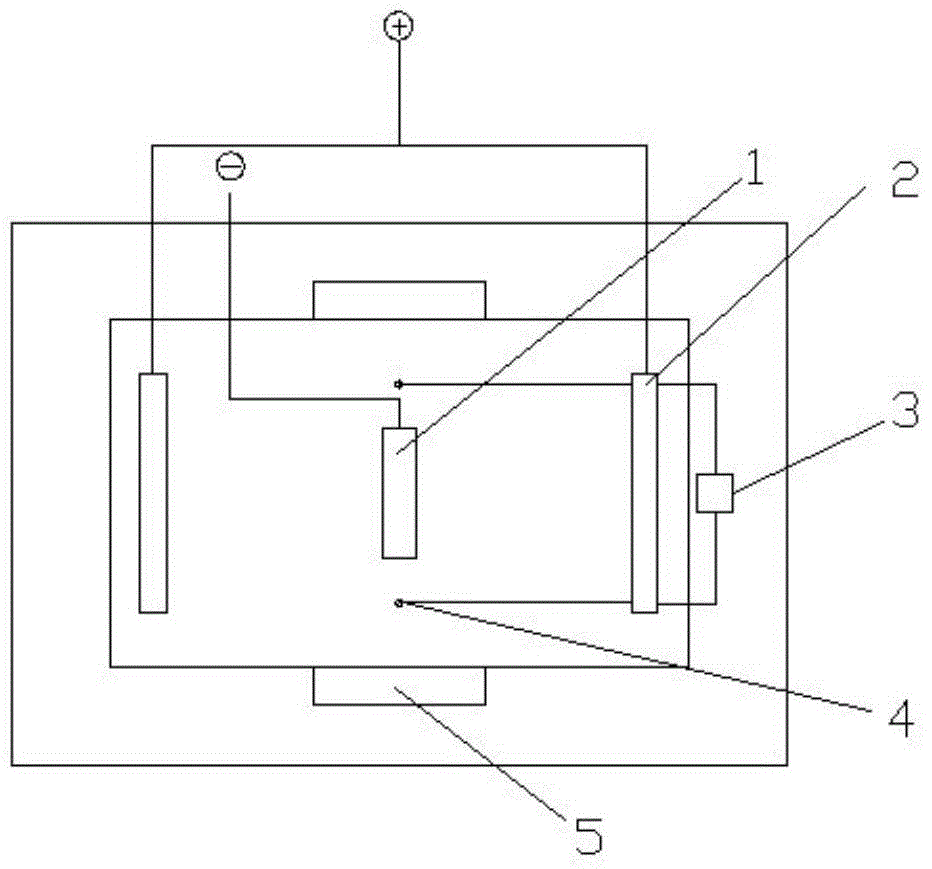

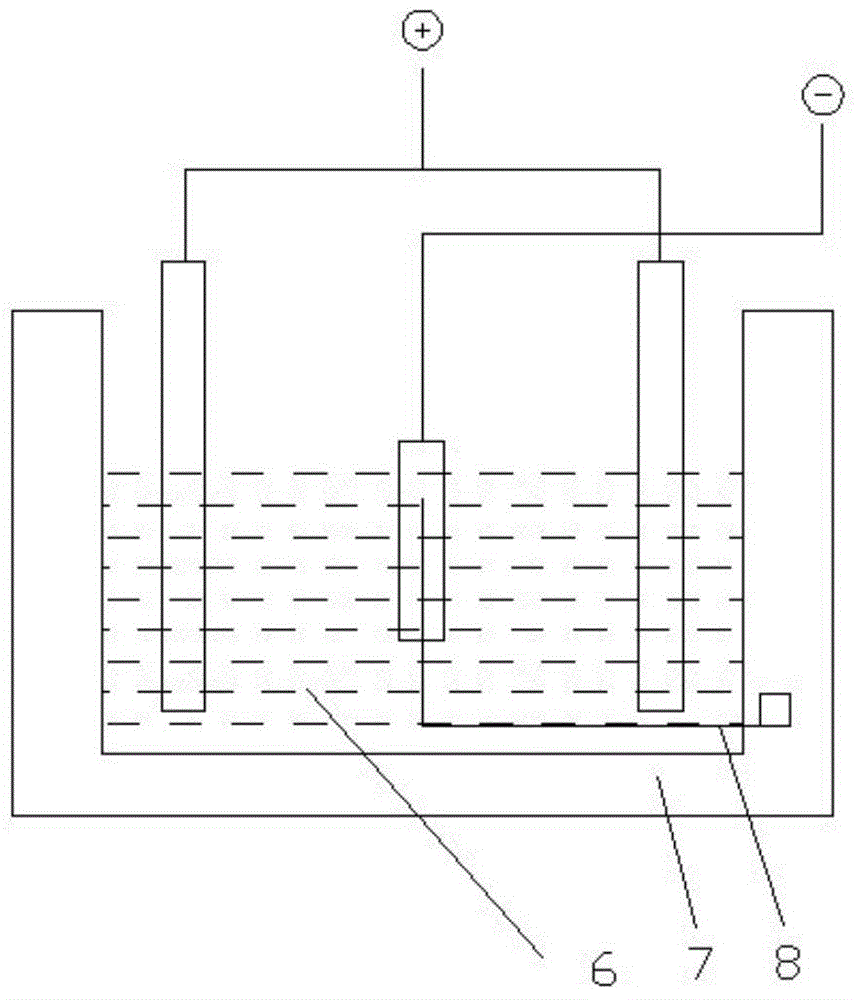

[0024] The electroplating equipment includes an electroplating anode 2, an electroplating cathode 1, an electroplating tank housing 7, and an electroplating solution 6, and also includes a temperature control device and an ultrasonic generator 5. The temperature control device includes a thermometer 4 and a temperature controller 3, and the thermometer 4 is located at On the side of the electroplating cathode 1, the thermostat 3 is located at one end of the electroplating tank housing 7, and the thermometer 4 and the thermostat 3 are connected by a connecting line 8; the ultrasonic generator 5 is located at the side of the electroplating tank housing 7; The outer surface of the connecting wire 8 has an insulating rubber layer.

[0025] The working process of the equipment is that during the electroplating process, the temperature control equipment is used to control and display the temperature of the electroplating solution 6; the ultrasonic generator 5 generates ultrasonic wav...

Embodiment 2

[0027] The electroplating equipment includes an electroplating anode 2, an electroplating cathode 1, an electroplating tank housing 7, and an electroplating solution 6, and also includes a temperature control device and an ultrasonic generator 5. The temperature control device includes a thermometer 4 and a temperature controller 3, and the thermometer 4 is located at On the side of the electroplating cathode 1, the thermostat 3 is located at one end of the electroplating tank housing 7, and the thermometer 4 and the thermostat 3 are connected by a wire 8; the ultrasonic generator 5 is located on the side of the electroplating tank housing 7. The temperature controller 3 and the ultrasonic generator 5 are connected by signals, and the temperature controller 3 controls the operation and stop of the ultrasonic generator 5 through signal transmission.

[0028] The working process of the equipment is that during the electroplating process, the temperature control equipment is used ...

Embodiment 3

[0030] The electroplating equipment includes an electroplating anode 2, an electroplating cathode 1, an electroplating tank housing 7, and an electroplating solution 6, and also includes a temperature control device and an ultrasonic generator 5. The temperature control device includes a thermometer 4 and a temperature controller 3, and the thermometer 4 is located at On the side of the electroplating cathode 1, the thermostat 3 is located at one end of the electroplating tank housing 7, and the thermometer 4 and the thermostat 3 are connected by a connecting line 8; the ultrasonic generator 5 is located at the side of the electroplating tank housing 7; The ultrasonic generating device 5 is set regularly, and the ultrasonic generating device 5 works intermittently.

[0031] The working process of the equipment is that during the electroplating process, the temperature control equipment is used to control and display the temperature of the electroplating solution 6; the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com