A Vacuum Cathode Arc Source with Discharge Arc Spots Covering the Target Surface

A cathode arc source and target surface technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the problems of limited total discharge current, concentrated ablation area, and limited discharge area, etc. Achieve the effect of improving the utilization rate of the target material and uniform ablation of the target surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with embodiment below in conjunction with accompanying drawing.

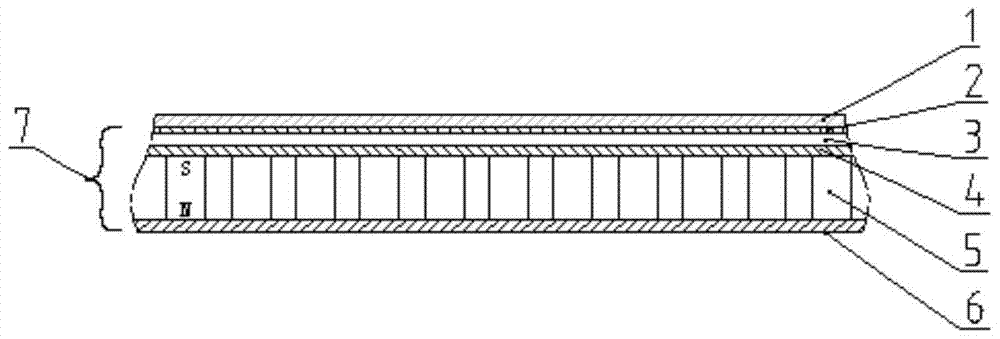

[0028] like image 3 As shown, a vacuum cathode arc source with arc spots all over the target surface discharge, including a rectangular flat target 1, the bottom surface of the flat target 1 is provided with a target base assembly 7, the flat target 1 and the target base assembly 7 are used Fasteners are tightly fitted and connected. In actual use, electrical insulation is maintained between the flat target 1 and the target base assembly 7; the target base assembly 7 is composed of cooling water channel components and magnetic circuit components stacked up and down; The flat cooling waterway 3 of the waterway metal upper cover sheet 2 and the cooling waterway metal bottom plate 4 is also provided with inlet and outlet ports. The cooling waterway metal upper cover sheet and the cooling waterway metal bottom plate are all made of red copper; the magnetic circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com