Method for purifying compound through ultrasonic crystal precipitation

A technology for compounds and target compounds, applied in chemical instruments and methods, dissolution methods, chemical/physical processes, etc., can solve the problems of low purity, time-consuming and labor-intensive, etc., and achieve improved purity, short time-consuming, detection and determination. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

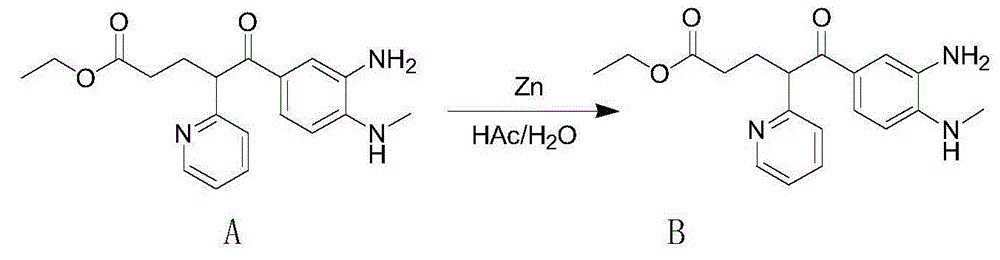

[0021] This example dabigatran etexilate synthetic process intermediate 3-[(3-amino-4-methylaminobenzoyl) (pyridin-2-yl)-amino] the synthesis of ethyl propionate is an example, described The synthetic reaction equation is as follows:

[0022]

[0023] The specific steps of the synthesis of the above reaction and the post-processing method of ultrasonic crystal forcing are as follows:

[0024] (1) Weigh A5.0g into a 250ml round bottom flask, add 10ml water and 10ml acetic acid to dissolve, stir for 2-5 minutes;

[0025] (2) Add 3.0g of zinc powder, stir and react at room temperature for 1 hour;

[0026] (3) After the reaction is completed, suction filtration is performed, and the filtrate is extracted with dichloromethane, and the dichloromethane phase is concentrated to obtain a reddish-brown oily substance B (containing impurities and pigments), with a purity of 87.5%.

[0027] (4) Add about 1-3ml of dichloromethane, force it to just dissolve under ultrasonication, then ...

Embodiment 2

[0031] This example dabigatran etexilate synthetic process intermediate 3-[(3-amino-4-methylaminobenzoyl) (pyridin-2-yl)-amino] synthetic of ethyl propionate, described synthetic reaction The equation is as follows:

[0032]

[0033] The synthetic concrete steps of above-mentioned reaction are as follows:

[0034] (1) Weigh A20g into a 500ml round bottom flask, add 50ml water and 50ml acetic acid to dissolve, stir for 2-5 minutes;

[0035] (2) Add 13g of zinc powder, stir and react at room temperature for 1 hour;

[0036] (3) After the reaction was completed, suction filtered, the filtrate was extracted with dichloromethane, and the dichloromethane phase was concentrated to obtain reddish-brown oil B (containing impurities and pigments), with a purity of 86.7%.

[0037] (4) Add about 3-5ml of dichloromethane, force it to just dissolve under ultrasonication, then add about 5-7ml of ethyl acetate, and continue ultrasonication until solids are precipitated;

[0038] (5) Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com