Low-layer elevator with no bottom pit

A bottomless pit and elevator technology, which is used in elevators, non-rotational vibration suppression, transportation and packaging, etc., can solve the problems of installation difficulties, difficulty in meeting the requirements of low-rise building elevators, and high construction costs, achieving low cost, saving construction costs, Guaranteed effect of safe space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

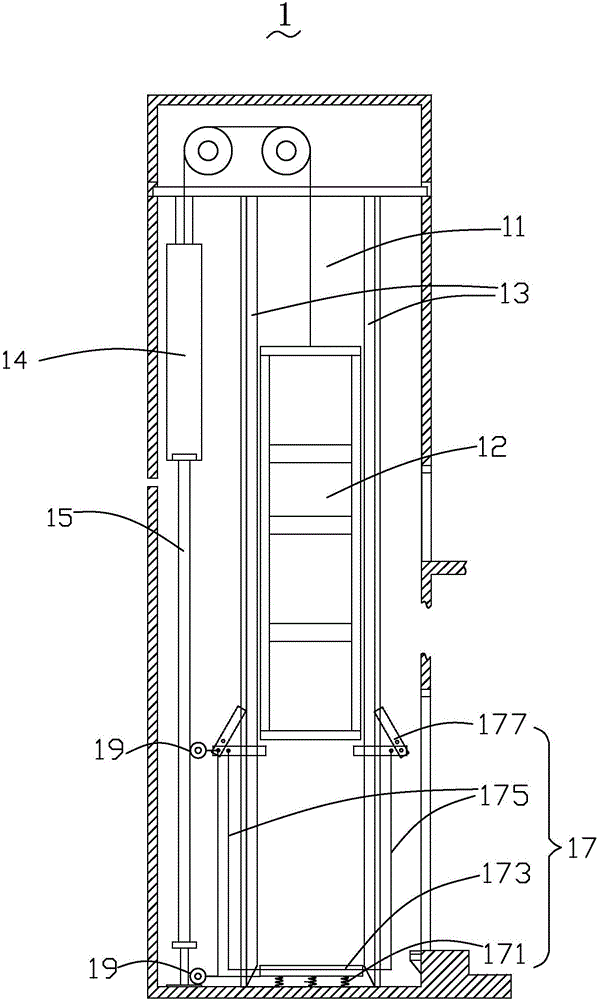

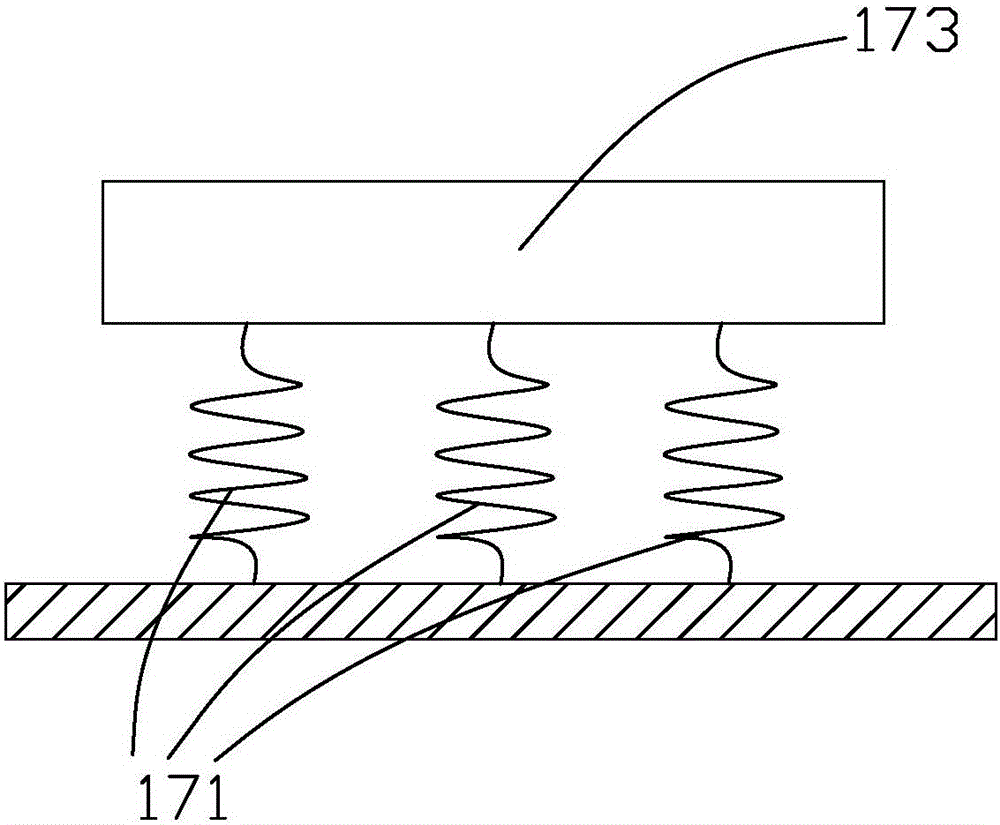

[0027] see figure 1 , is a schematic structural view of the bottomless pit low-floor elevator in Embodiment 1 of the present invention. The bottomless pit low-rise elevator 1 comprises an elevator shaft 11 and an elevator car 12, two guide rails 13, an elevator counterweight 14, a leading screw 15, a safety device 17 and a safety switch 19 accommodated inside it, and the elevator car 12 Sandwiched between the guide rails 13, the elevator counterweight 14 ring is set on the screw 15, the safety device 17 is located at the bottom of the elevator shaft 11, and the safety switch 19 is installed on the safety device 17 , and electrically connected with the elevator safety circuit.

[0028] The elevator shaft 11 is a shaft with accommodation space, and its height is suitable for buildings with 2-7 floors. The bottom of the elevator shaft 11 is a bottomless pit or a shallow pit.

[0029] The elevator car 12 is a box-shaped space for the elevator to carry and transport people and ma...

Embodiment 2

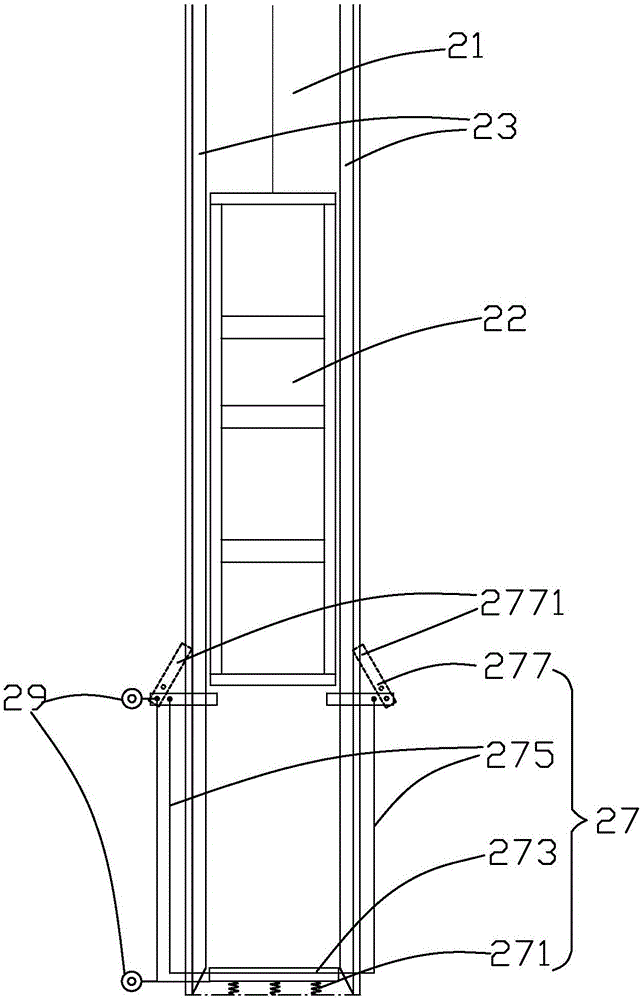

[0047] Please also see image 3 and Figure 4 , image 3 It is a structural schematic diagram of the elevator car safety device of the bottomless pit low-floor elevator in Embodiment 2 of the present invention, Figure 4 It is a structural schematic diagram of an elevator counterweight safety device for a bottomless pit low-floor elevator according to Embodiment 2 of the present invention. The bottomless pit low-rise elevator includes an elevator shaft 21 and an elevator car 22, two car guide rails 23, an elevator counterweight 24, two counterweight guide rails 25, a safety device 27 and a safety switch 29 accommodated inside the elevator shaft 21. The car 22 is sandwiched between the car guide rails 23, the elevator counterweight 24 is sandwiched between the counterweight guide rails 25, the safety device 27 is located at the bottom of the elevator shaft 21, and the safety switch 29 is installed on the safety device 27, and it is electrically connected with the elevator sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com