Glass bottle delivery device

A conveying device and glass bottle technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, poor work environment and high labor intensity, and achieve high work efficiency, low labor intensity and good work environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below:

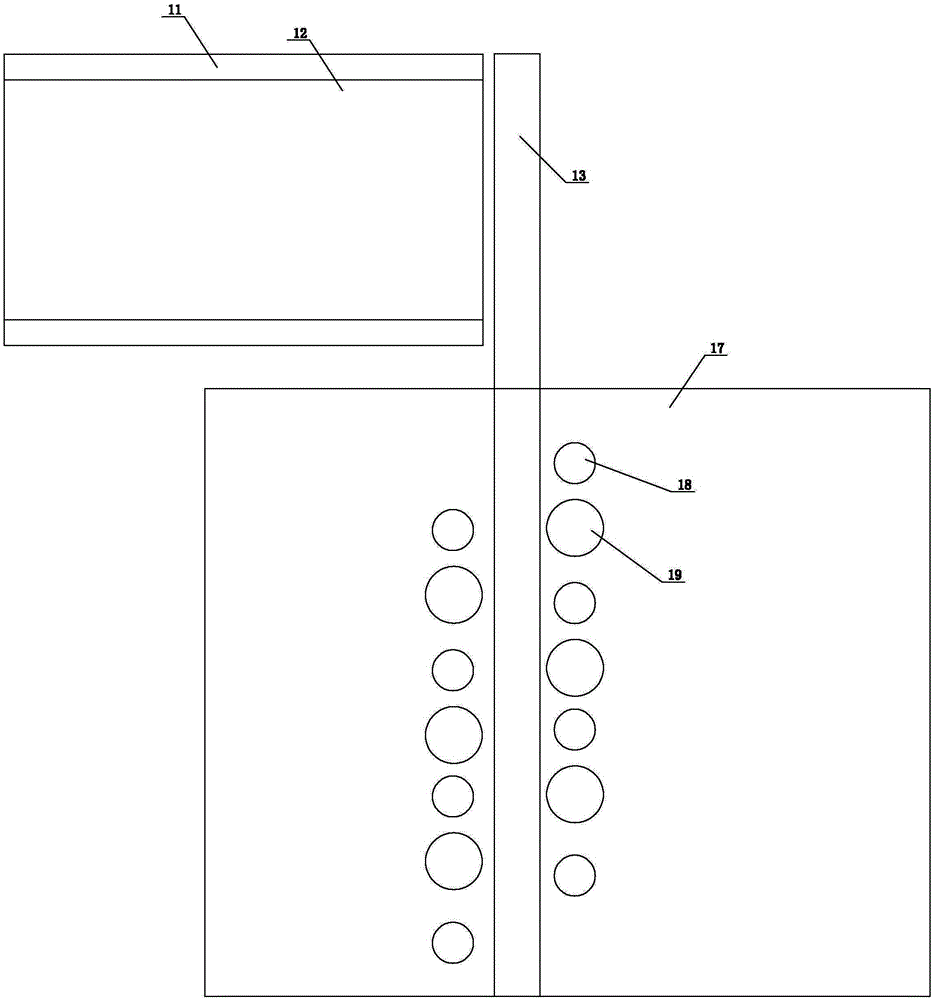

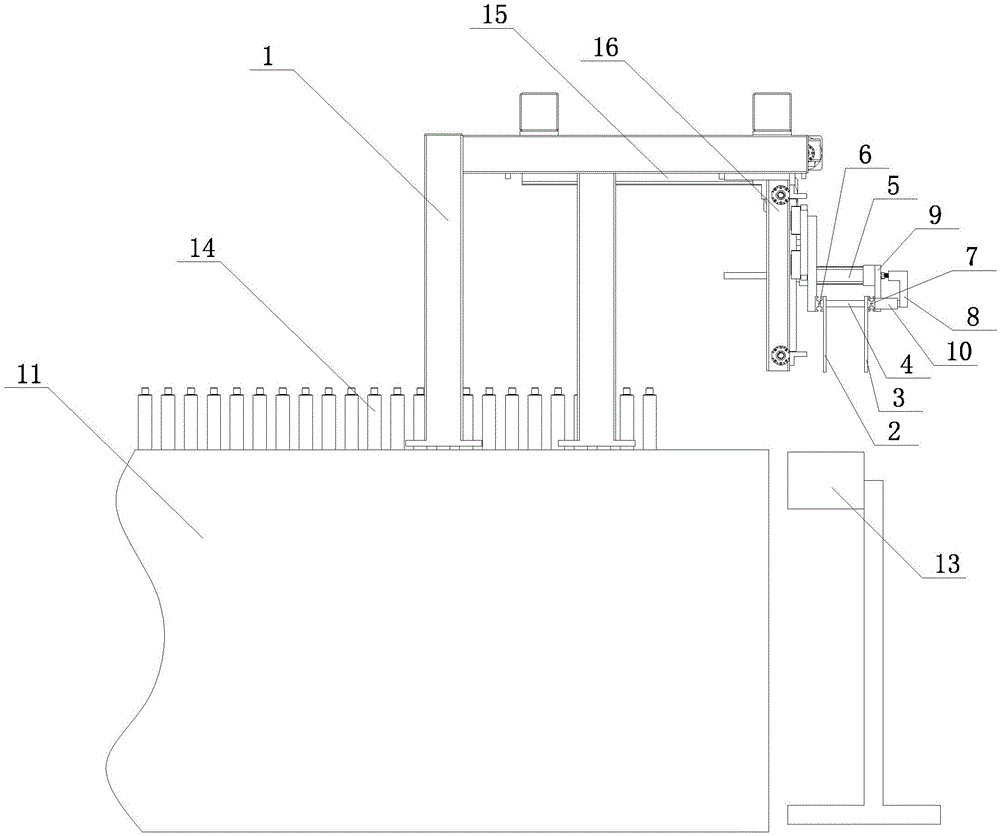

[0019] The glass bottle conveying device of the present invention comprises a gantry support 1, a tempering furnace conveyor belt 12 passes under the gantry support 1, an intermediate conveyor belt 13 is arranged adjacent to the gantry support 1, and the intermediate conveyor belt 13 leads to a sorting chamber 17, and the intermediate conveyor belt The two sides of the part of 13 that is located in the sorting chamber 17 are provided with several stations 18, and recovery ports 19 are provided between the adjacent stations 18 along the conveying direction; Line moving mechanism 15, the moving end of the first linear moving mechanism 15 is provided with the second linear moving mechanism 16 that moves along the vertical direction, and the moving end of the second linear moving mechanism 16 is provided with clamping bottle mechanism.

[0020] One station 18 is for one worker to sit or stand, that is, one positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com