Fixing device for roll-on and roll-off container

A technology for fixing devices and containers, which is applied in the directions of packaging, transportation, packaging, containers, etc. It can solve the problems of no limit fixing device, ship shaking, potential safety hazards, etc., so as to avoid ship shaking or capsizing, reasonable setting, and reduced safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

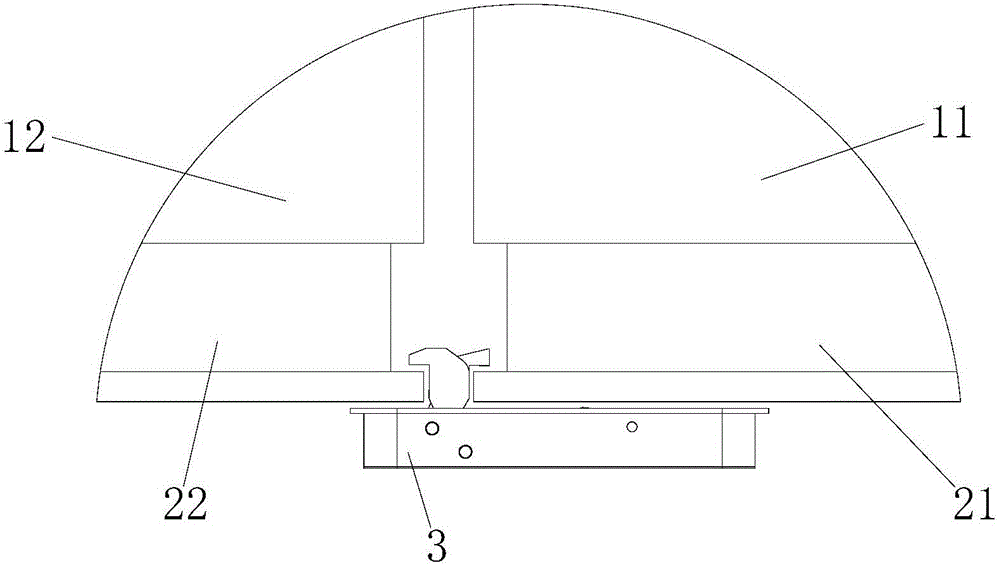

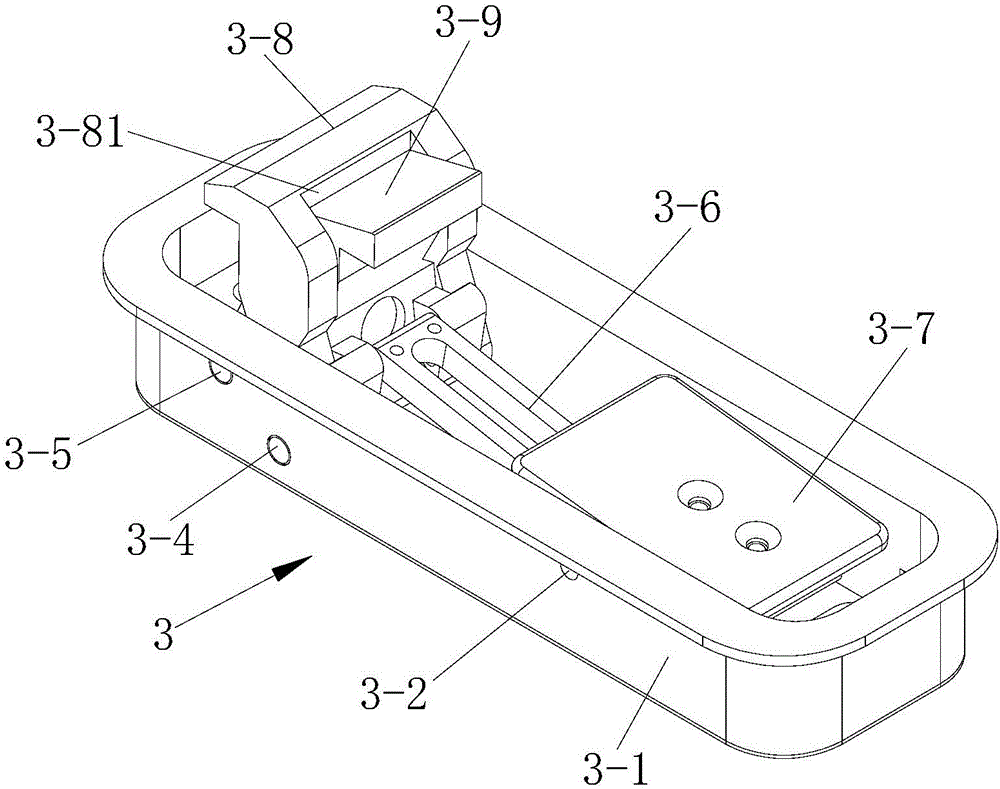

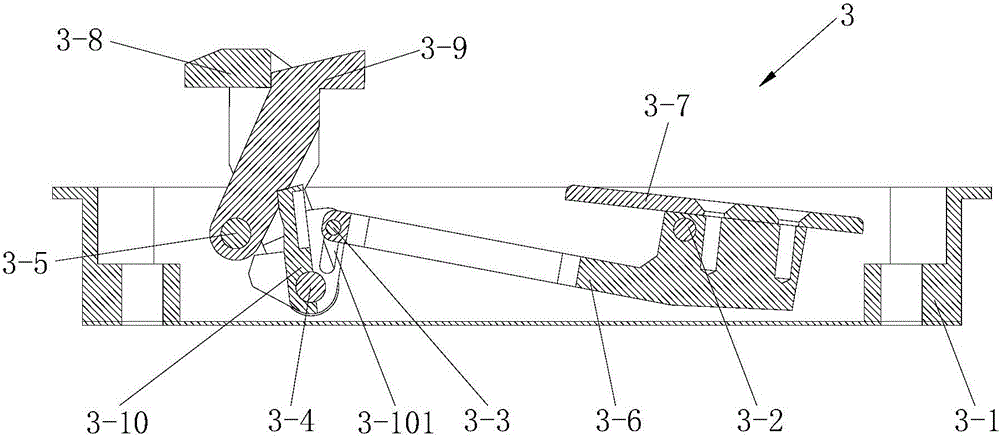

[0023] Such as Figure 2 to Figure 5 As shown, the rolling container fixing device according to the present invention includes a fixing body 3, and the fixing body 3 includes a base 3-1 and an arm rotation shaft 3-3, and the right inner side of the base 3-1 The side wall of the cavity is hinged with a pedal arm 3-6 through the plate rotation shaft 3-2, and the left inner cavity side wall of the base 3-1 is hinged with a locking hook B3-9 through the lock B rotation shaft 3-5; the base 3 The side wall of the left inner cavity of -1 is hinged with locking hook A3-8 and pulling fork 3-10 by pulling out lock A rotating shaft 3-4.

[0024] A pedal 3-7 is fixedly connected to the upper surface of the right end of the pedal arm 3-6, and the left end of the pedal arm 3-6 is hinged to the waist hole 3-101 of the fork 3-10 through the arm rotating shaft 3-3.

[0025] One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com