Automatic tin pick-up machine

A tin-dipping machine and automatic technology, applied in the directions of tin-feeding devices, auxiliary devices, metal processing equipment, etc., can solve the problems of local poor tin-dipping, smoke and smell, and many residues, etc., to solve the problems of poor tin-dipping, The effect of uniform and full tin and stable transportation of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

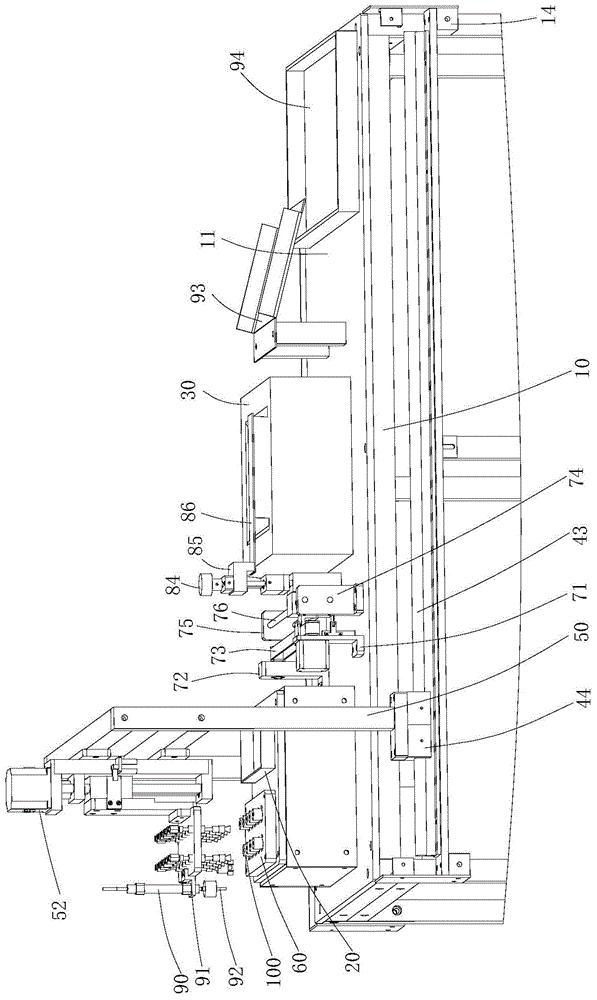

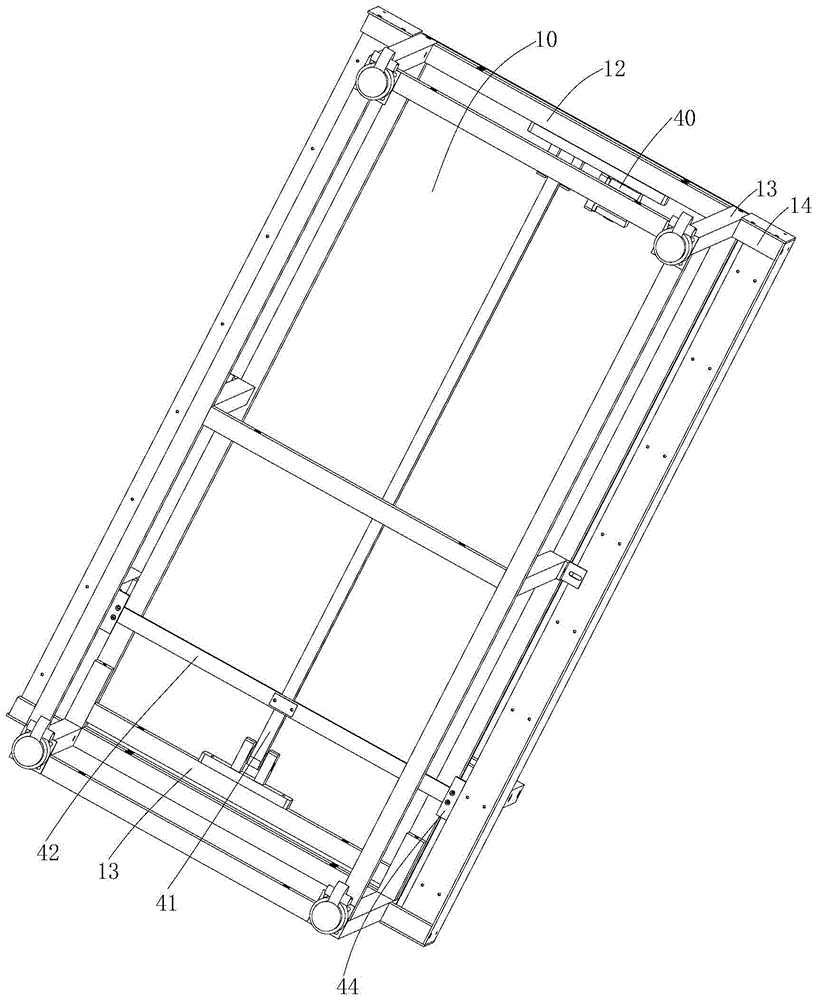

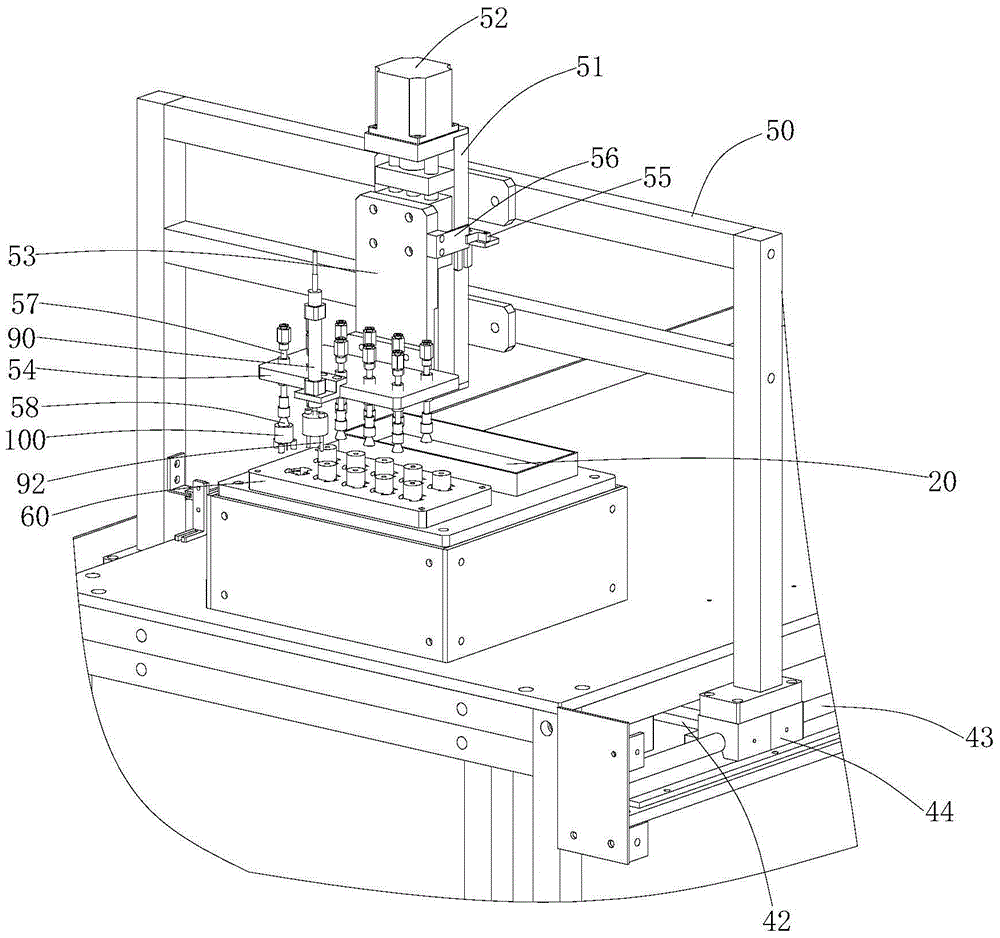

[0051] refer to figure 1 , an automatic tin dipping machine, including a workbench 10, the workbench 10 is a support box composed of 16 aluminum profiles and a sealing plate, and four corners of the bottom surface of the workbench 10 are equipped with 4 360-degree rotatable Mafu wheels. A rosin box 20 and a tin pool 30 located on the table top 11 of the workbench are sequentially arranged along the X-axis direction of the workbench. The tin pool 30 is a tin pool with an electric heating structure, and the tin material is placed in the tin pool. , can be directly heated and melted. A linear drive device is arranged on the workbench, and a lifting and picking device driven by the linear drive device is displaced along the X-axis direction of the workbench.

[0052] refer to figure 1 and figure 2, the driving device includes a first stepping motor 40, a first pulley, a second pulley, a belt 41, a drive plate 42, two guide rails 43 and a slide block 44 symmetrically arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com