Automatic cleaning device of photovoltaic module

A photovoltaic module and automatic cleaning technology, applied in the fields of photovoltaic modules, photovoltaic power generation, and cleaning methods using tools, etc., can solve the problems of reducing the power generation of components, the cleaning effect is general, and the loss of power generation, so as to simplify the structural components of the device and ensure the The effect of running stability and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

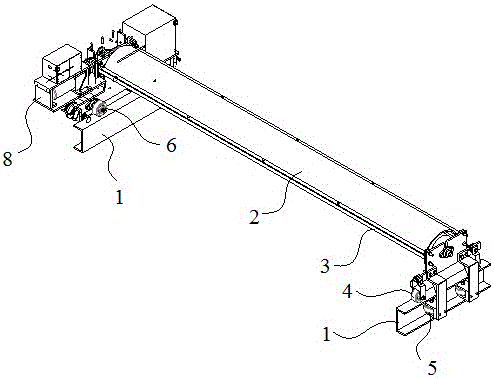

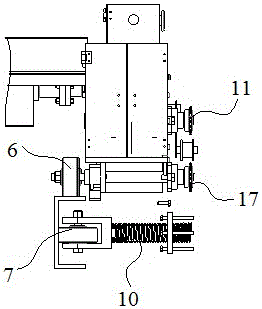

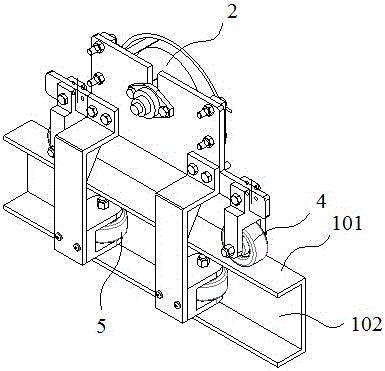

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the automatic cleaning device for photovoltaic modules of the present invention mainly includes a track, a cleaning structure, a driving and walking structure, and the like. The track includes two tracks 1, which are symmetrically arranged on both sides of the photovoltaic module. The track 1 includes at least a running plane 101 on the top and a balance groove 102 on the side. A typical track 1 structure can use I-shaped steel . The cleaning structure includes a cleaning shaft 2 and a cleaning brush 3 arranged on the cleaning shaft 2. The cleaning shaft 2 is set between two rails 1 and is located above the photovoltaic module. The cleaning brush is driven by rotation to clean the surface of the photovoltaic module.

[0031] The driving walking structure includes traveling wheels, balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com