Multifunctional glue dispensing device

A dispensing device and multi-functional technology, applied in the field of multi-functional dispensing devices, can solve the problems of uncontrollable extrusion volume, unsatisfactory dispensing effect, inconvenient movement, etc., achieve good effect, ensure dispensing effect, Epoxy uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

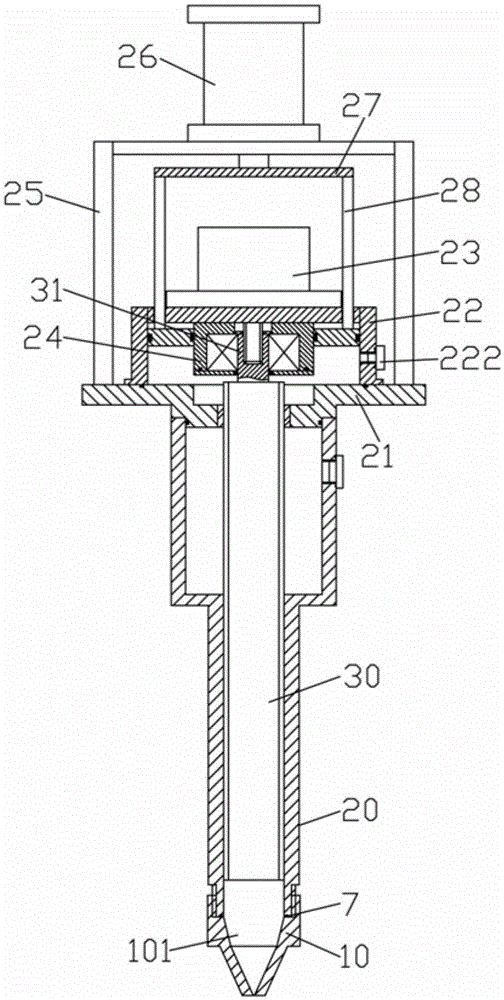

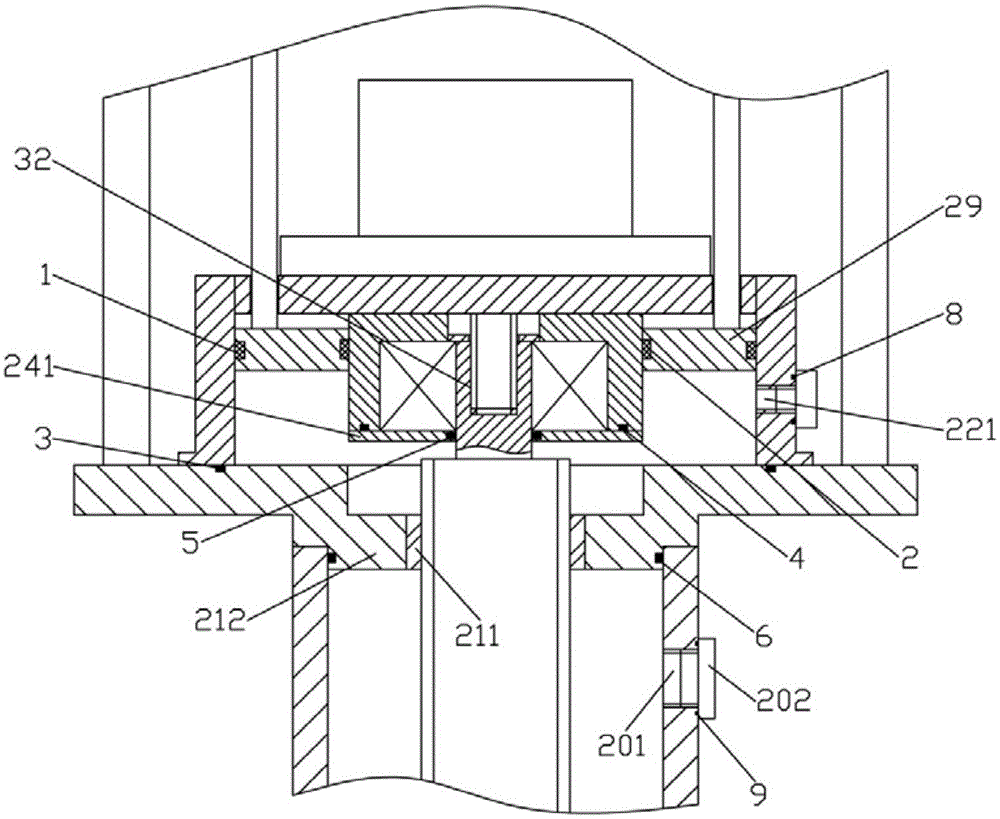

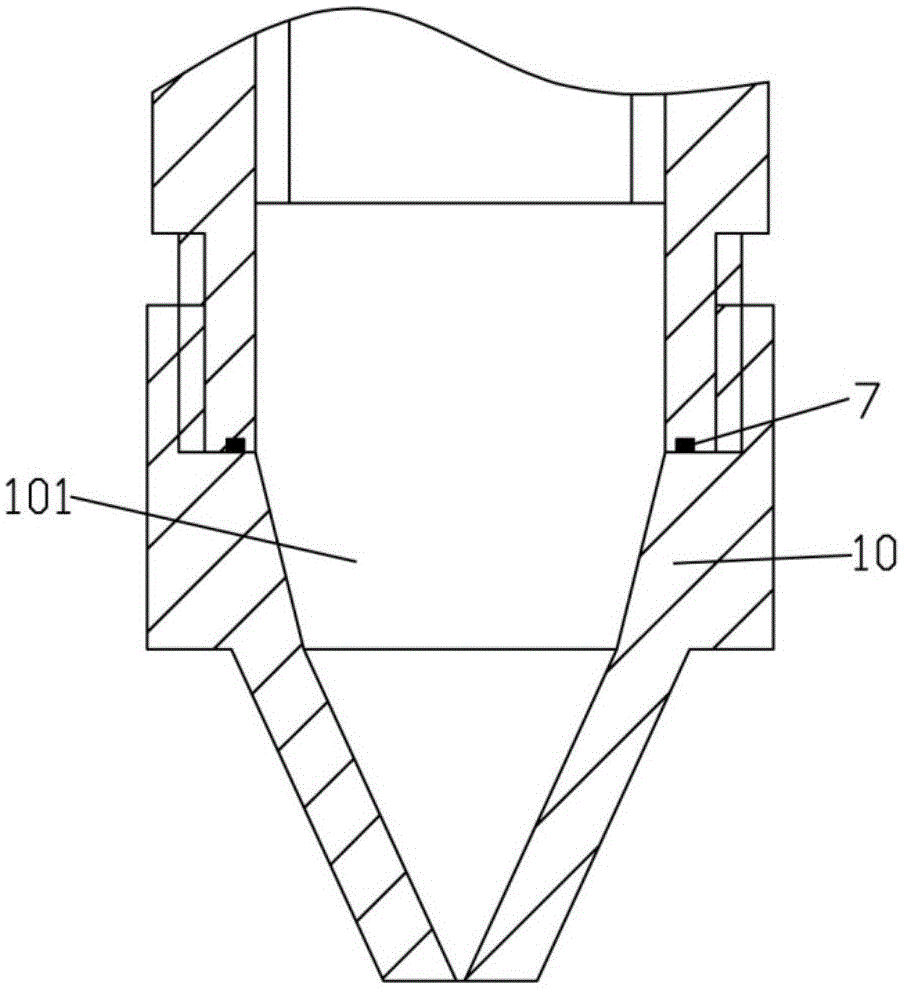

[0022] Examples, see e.g. Figures 1 to 3 As shown, a multifunctional dispensing device includes a dispensing head 10 and a dispensing cylinder 20, the bottom of the dispensing cylinder 20 is fixed with the dispensing head 10, and the inner wall of the dispensing cylinder 20 is inserted Covered with a feed screw 30, the top of the dispensing cylinder 20 is fixed with a top end cover 21, the top surface of the top end cover 21 is fixed with an upper barrel 22, and the top plate of the upper barrel 22 is fixed with a drive motor 23, the drive motor The output shaft of 23 passes through the top plate of the upper barrel 22 downwards, the bottom surface of the top plate of the upper barrel 22 is fixed with a connecting block 24, and the top end 31 of the feed screw 30 stretches out of the top end cover 21 and is hinged in the connecting block 24 , the output shaft of the drive motor 23 is a spline shaft, and the output shaft of the drive motor 23 extends into the connection block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com