Movement mechanism with multifunctional dispensing device

A technology of dispensing device and moving mechanism, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uncontrollable extrusion amount, unsatisfactory dispensing effect, inconvenient movement, etc., and achieve good results , Guarantee the dispensing effect and the uniform effect of dispensing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

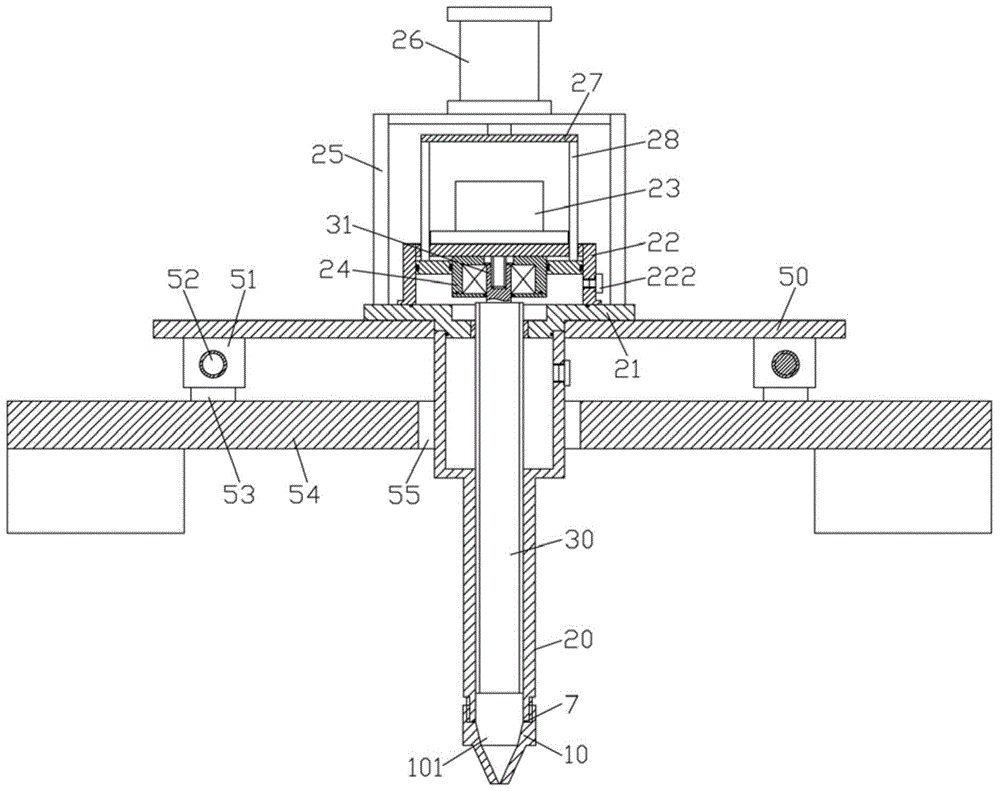

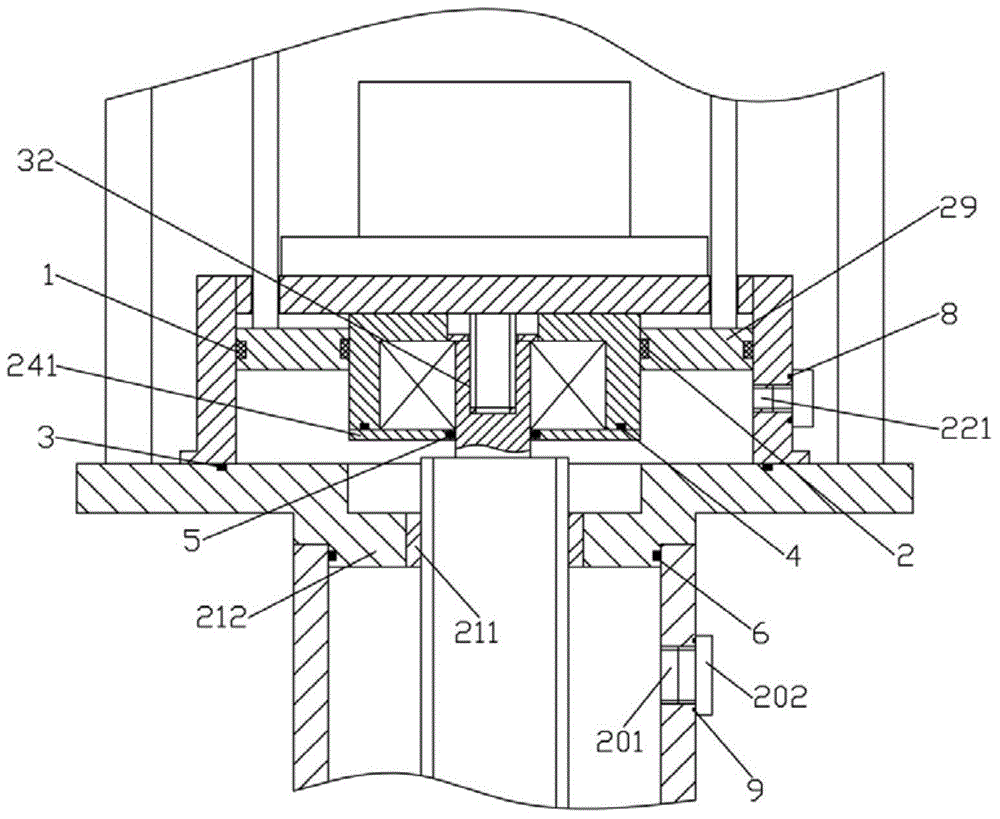

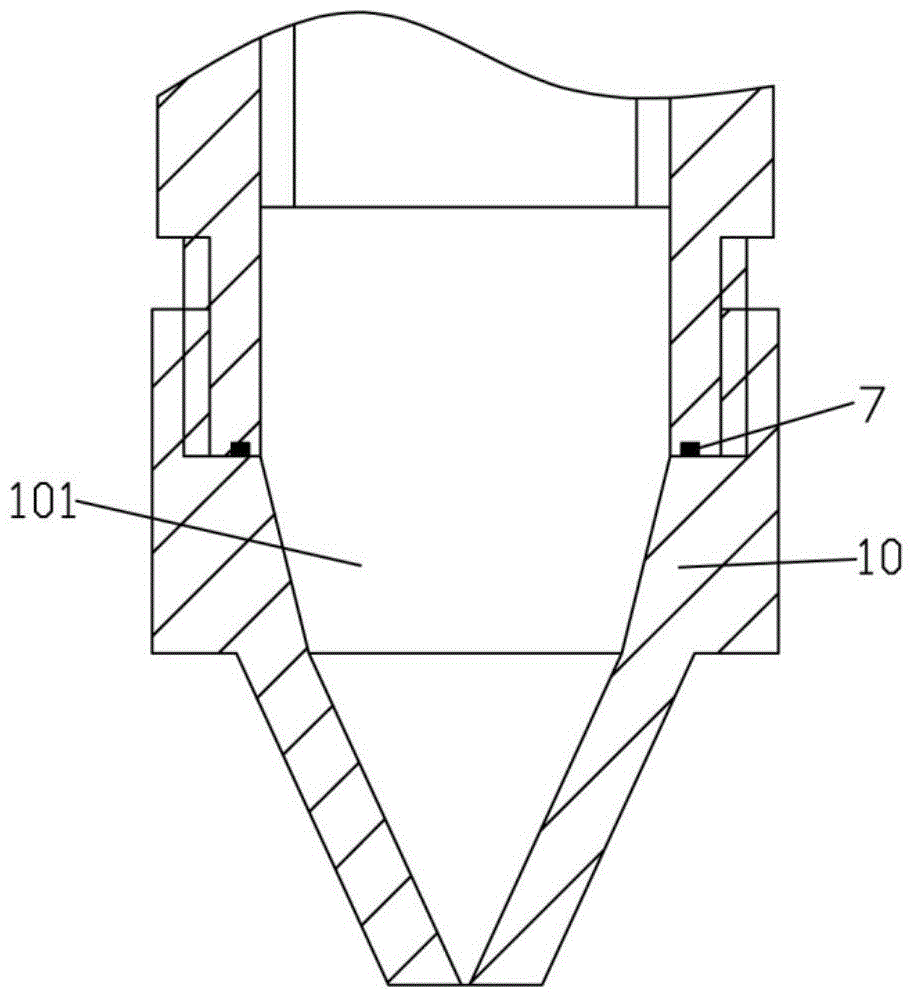

[0024] Examples, see e.g. Figures 1 to 4 Shown, a kind of moving mechanism that adopts multifunctional dispensing device, comprises dispensing head 10 and dispensing barrel 20, the bottom end of described dispensing barrel 20 is fixed dispensing head 10, the dispensing barrel 20 A feed screw 30 is inserted into the inner wall, and a top end cap 21 is fixed on the top of the dispensing cylinder 20. The top end cap 21 is fixed on the connection plate 50, and the middle part of the connection plate 50 has a connection jack. The dispensing cylinder body 20 is inserted into the connecting socket, and the two sides of the bottom surface of the connecting plate 50 are fixed with moving blocks 51, and the moving blocks 51 are screwed in the adjusting screw rods 52, and the two ends of the two adjusting screw rods 52 are hinged on two support plates 53, The support plate 53 is fixed on the base frame 54, the middle part of the base frame 54 has a long slot 55, the lower part of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com