Air-ejected anti-blocking system for cane harvester

A harvester, jet-type technology, applied in the field of jet-type anti-blocking system of sugarcane harvesters, can solve problems such as inability to quickly discharge, channel blockage, sugar loss, etc., and achieve the effect of ensuring normal harvesting work, preventing blockage, and efficient and reasonable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technology will be further described below in conjunction with the accompanying drawings.

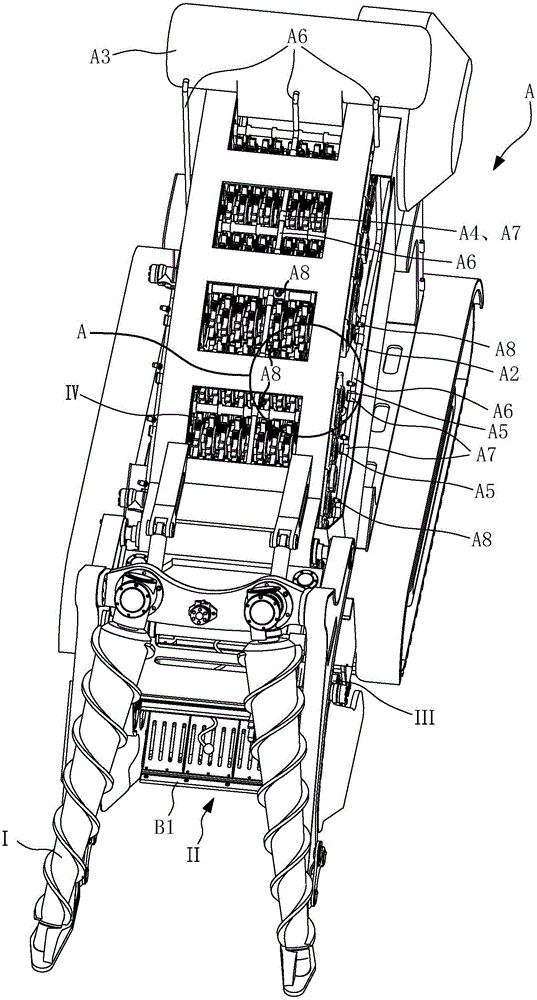

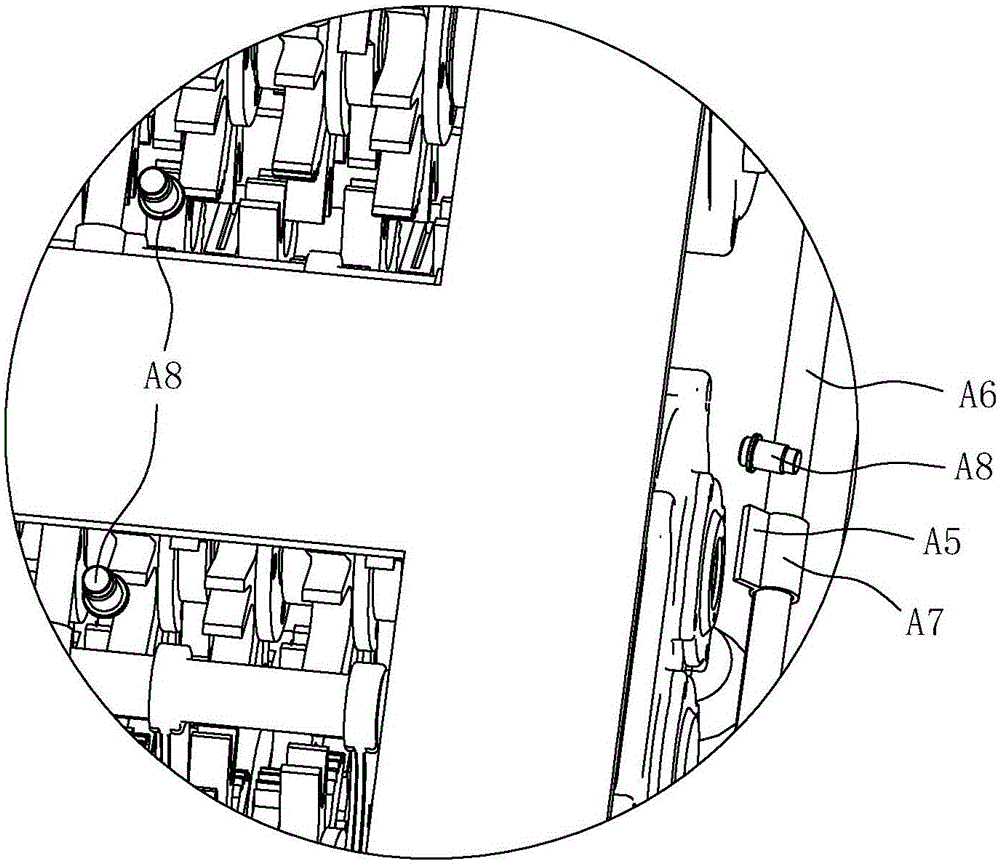

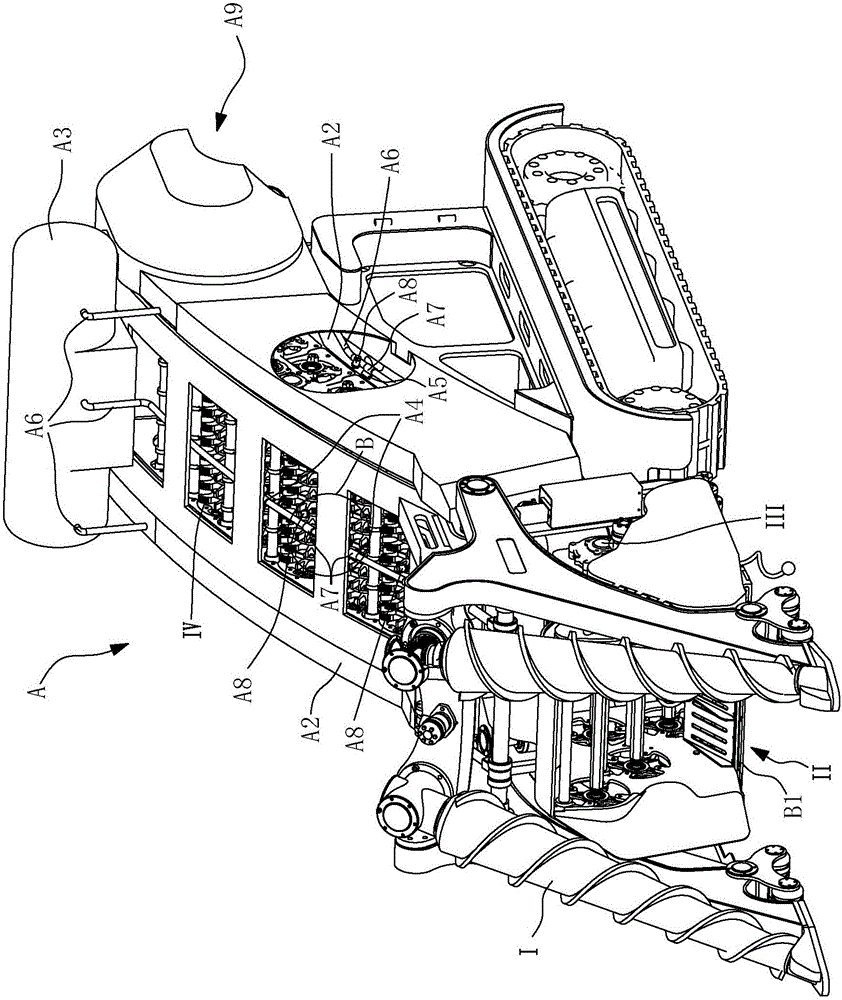

[0015] The jet-type anti-blocking system of the sugarcane harvester of the present embodiment includes a harvester main body A, the harvester main body A is provided with a suction passage A2 for sucking and discharging crushing blades, and an air compressor and an air storage tank are arranged on the harvester main body A A3, the first air nozzle A4 is provided at the place where blockage is likely to occur on the path of sugarcane stalk transmission in the stripping channel of the harvester main body A, and a plurality of second air jets are arranged in the suction channel A2 along the direction of the suction channel A2 Nozzle A5, the outlet of the suction channel A2 is provided with an air blower blowing outward, the first air nozzle A4 and the second air nozzle A5 communicate with the air storage tank A3 through the pipeline A6, and the first air nozzle A4 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com