Sugarcane harvester used leaf stripping wheel assembly with anti-entanglement and shredding functions

A technology for stripping impellers and harvesters, which is used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of sugar loss, easy winding and stripping channels, unreasonably increasing engine output power, etc., to avoid blockage, Guarantee the effect of normal harvesting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technology will be further described below in conjunction with the accompanying drawings.

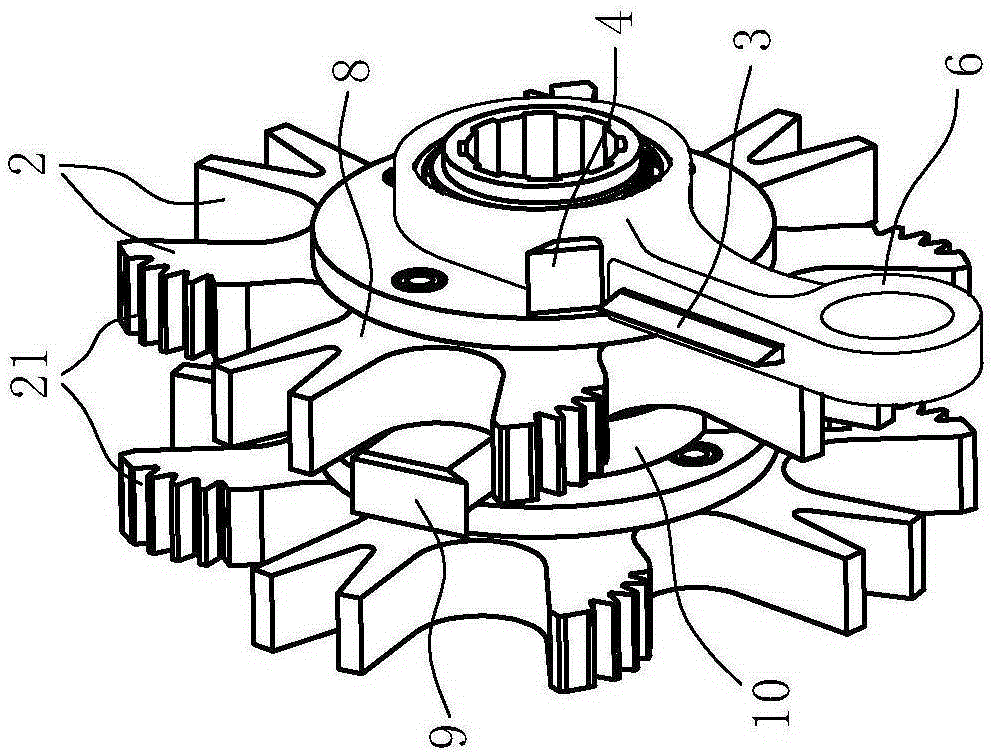

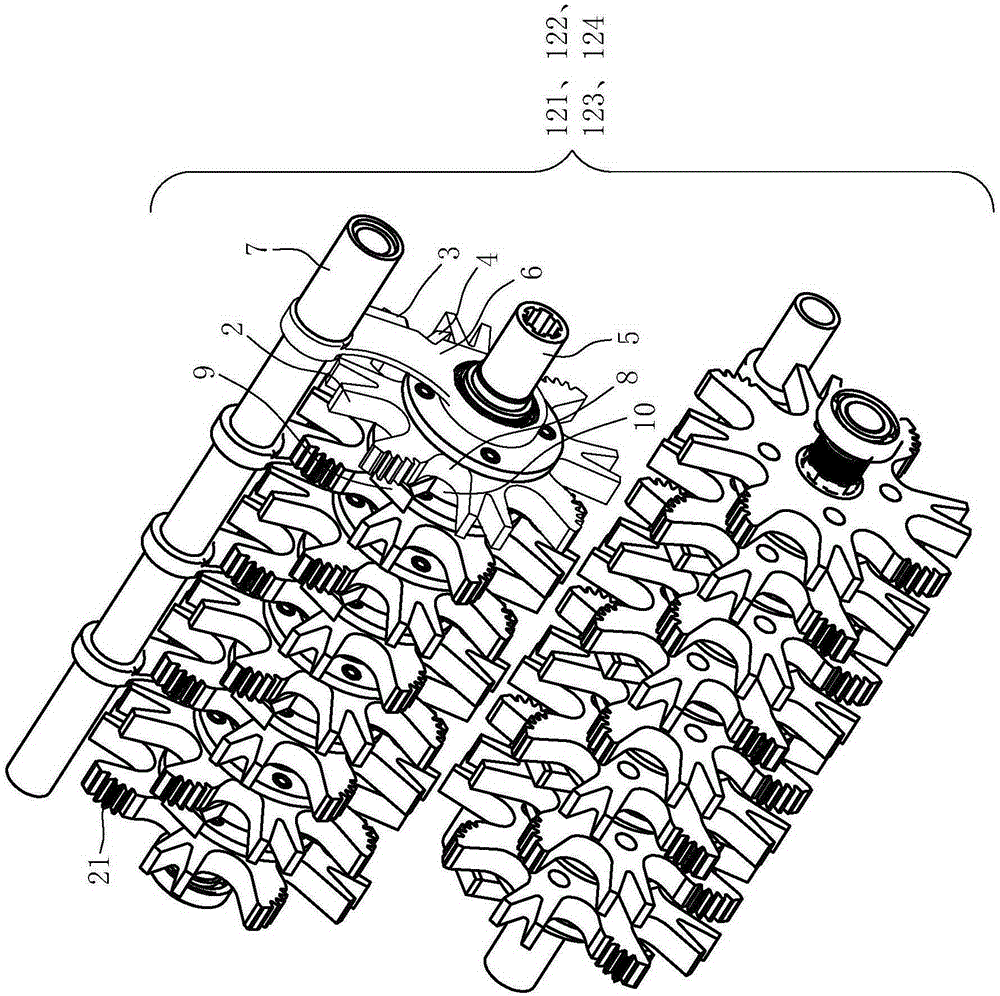

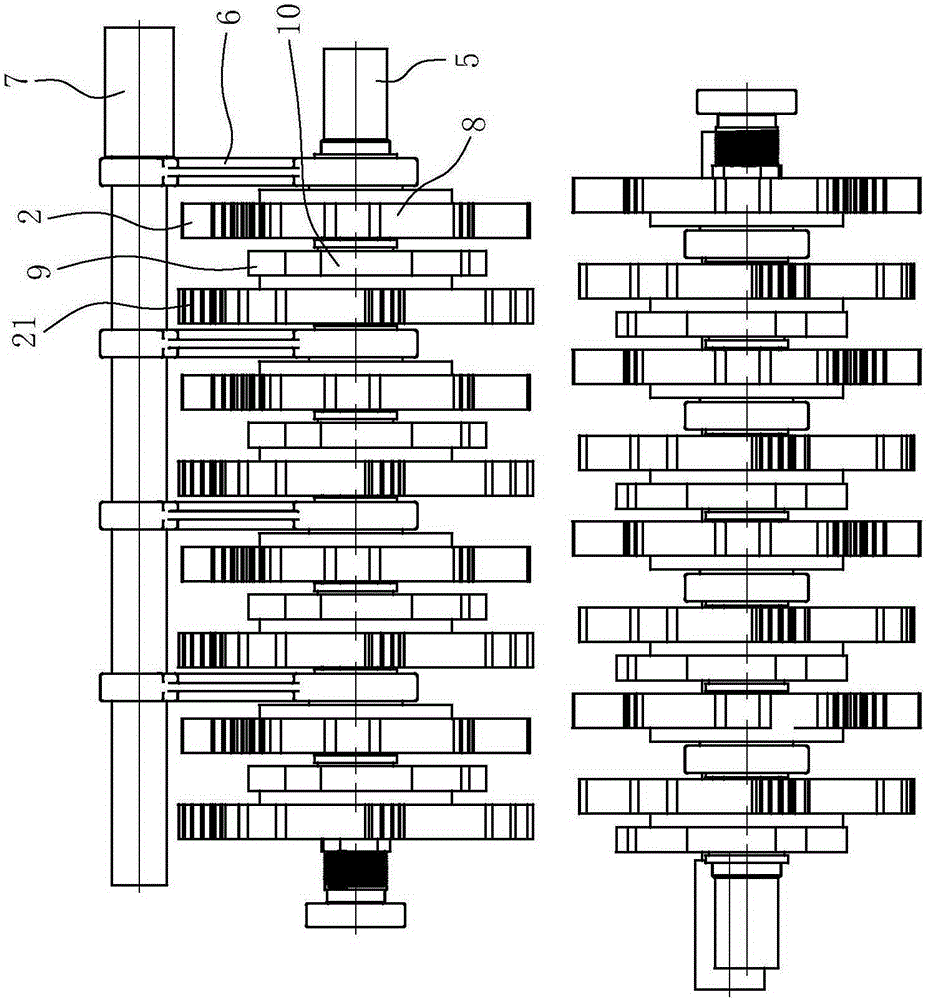

[0016] The sugarcane harvester stripping impeller assembly with both resistance and crushing functions of the present embodiment includes a stripping impeller body 8 made of useful rubber, and is provided with an anti-winding device next to the stripping impeller body 8, and the anti-winding device is rotated Knife 9, fixed anti-wrapping arm 6 and the pulverizing blade assembled on the anti-wrapping arm 6 constitute, and the rotating wheel 10 that rotates with stripping impeller body 8 is socketed beside stripping impeller body 8, and rotating knife 9 is located at the rotating On the wheel 10, the rotating knife 9 is a "7" shaped knife, and the rotating knife 9 is facing the same direction as the rotating direction. The longitudinal crushing blade 3 and the horizontal crushing blade 4, the crushing blade blade faces a opposite to the direction of rotation b of the stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com