Sludge treatment device having dehydrator

A technology of sludge treatment and dehydrator, which is applied in the direction of sludge treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problem of reducing sludge volume, shorten operation time and increase sludge treatment The effect of reducing the amount and shortening the discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings to facilitate implementation by those skilled in the art. However, the present invention can be embodied in various forms, and is not limited to the following examples.

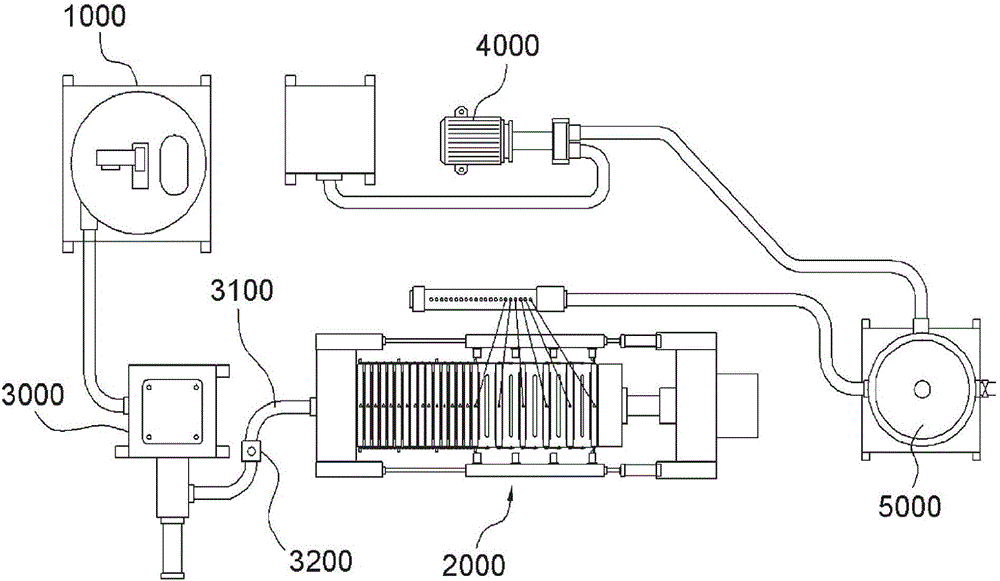

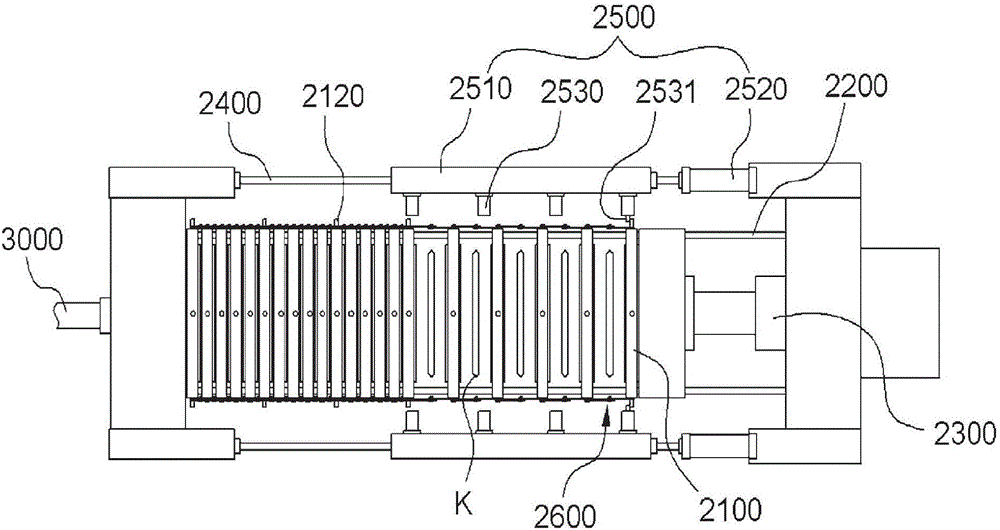

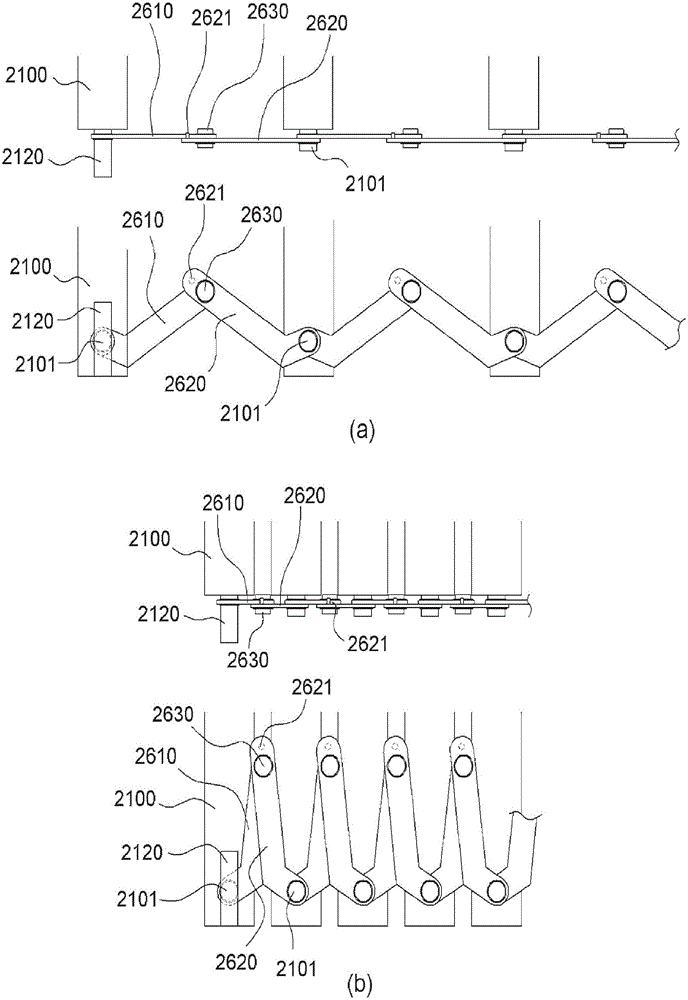

[0025] figure 1 It is a schematic diagram of the overall system of the sludge treatment device equipped with a dehydrator of the present invention, figure 2 is a schematic plan view of the dehydrator of the present invention, image 3 It is a schematic cross-sectional view of the dewatering plate arranged on the dehydrator of the present invention, Figure 4 It is an action state diagram of the connecting rod and the driving sequence of the connecting rod of the present invention, Figure 5 It is a schematic front view of the dewatering plate arranged on the dehydrator of the present invention, Image 6 It is a schematic plan view of the sequence in which the dewatering plate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com