Insulation operating rod for fastening pin insulator nuts in electrified mode

A technology of insulating operating rod and nut, applied in the direction of overhead line/cable equipment, etc., can solve the problems of the operator failing to obtain the isolation method for live work, the inconvenience of replacing the fastening head, and the harm of the operator, so as to meet the requirements of high-altitude fastening Operational requirements, ensuring safety, and the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

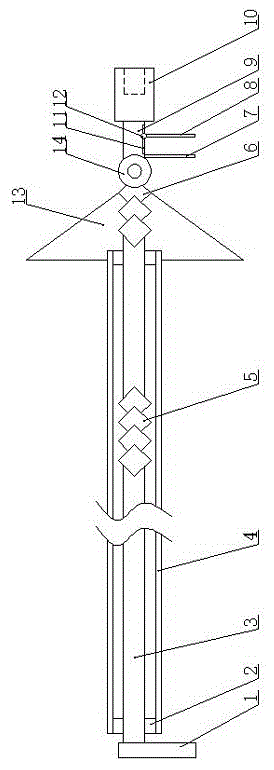

[0011] Example: such as figure 1 As shown, the insulating operating rod for fastening the needle bottle nut with electricity includes an insulating sleeve rod 4, and a rotating rod 3 inserted into the insulating sleeve rod 4. The inside of the insulating sleeve rod 4 is a cavity, and two ports are provided with The bearing 2 and the upper and lower parts of the rotating rod 3 are placed in the bearing 2 to form a rotational connection with the insulating sleeve rod 4 . The upper and lower ends of the rotating rod 3 stretch out the insulating sleeve rod 4, and the upper end extension is a rod head 9, and a sleeve 10 is installed on the rod head 9, and a rotating handle 1 is installed on the lower end extension. A fixed plate 7 and a slide plate 8 with an adjustable distance are arranged at the side wall of the rod head 9 . An isolation cover 9 is arranged on the rod head 9 on the lower side of the fixed plate 7 .

[0012] A chute 11 is provided on the rod head 9, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com