Ship unloader metering mode control method

A mode control and ship unloader technology, applied in the field of ship unloader control, can solve the problems of many equipment failure points, complex system, heavy maintenance workload, etc., and achieve the goal of improving measurement accuracy, high measurement accuracy and good buffering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

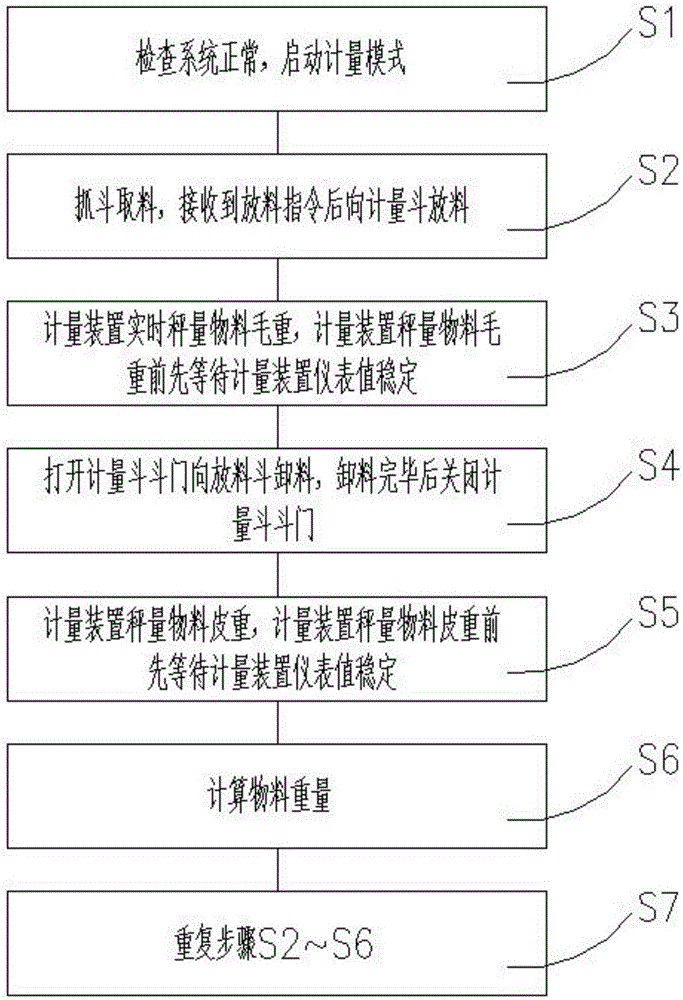

[0046] Each step of the present invention will be further described in detail below.

[0047] S1. Check that the system is normal, and start the metering mode. In the metering mode, the operator of the ship unloader has no right to control the metering process.

[0048] When starting to work, check whether the various parts and mechanisms of the ship unloader are in normal condition and start the metering mode. In the non-metering mode, the on-site operators can control each step of the metering process by themselves. In the metering mode, the operator has no right to control the metering process, but must measure according to the flow set by the metering mode. For the convenience of management and operation, The metering mode can be remotely selected and locked, so that it can be guaranteed to work in the metering mode when needed, preventing the operator of the ship unloader from using the non-metering mode privately for the sake of efficiency or trouble, resulting in inaccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com