Rebar Anchored Connection Structure and Connection Method of Prefabricated Concrete Members

A prefabricated concrete and steel bar anchoring technology, applied to structural elements, building components, manufacturing tools, etc., can solve the problems of increased overlapping length of steel bars, increased amount of grouting materials, random construction operations, etc., to achieve small size and enhanced bonding Good performance and connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

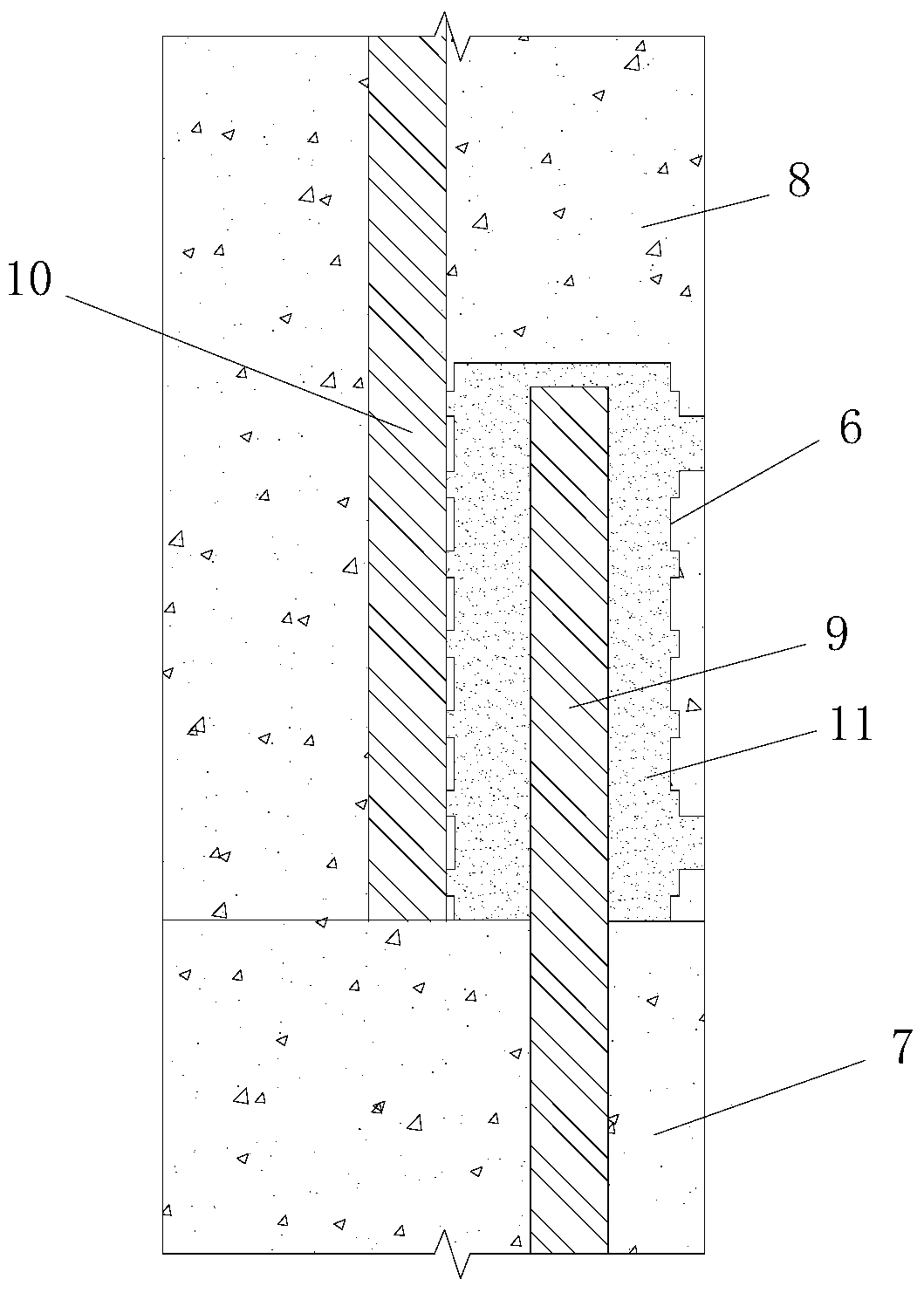

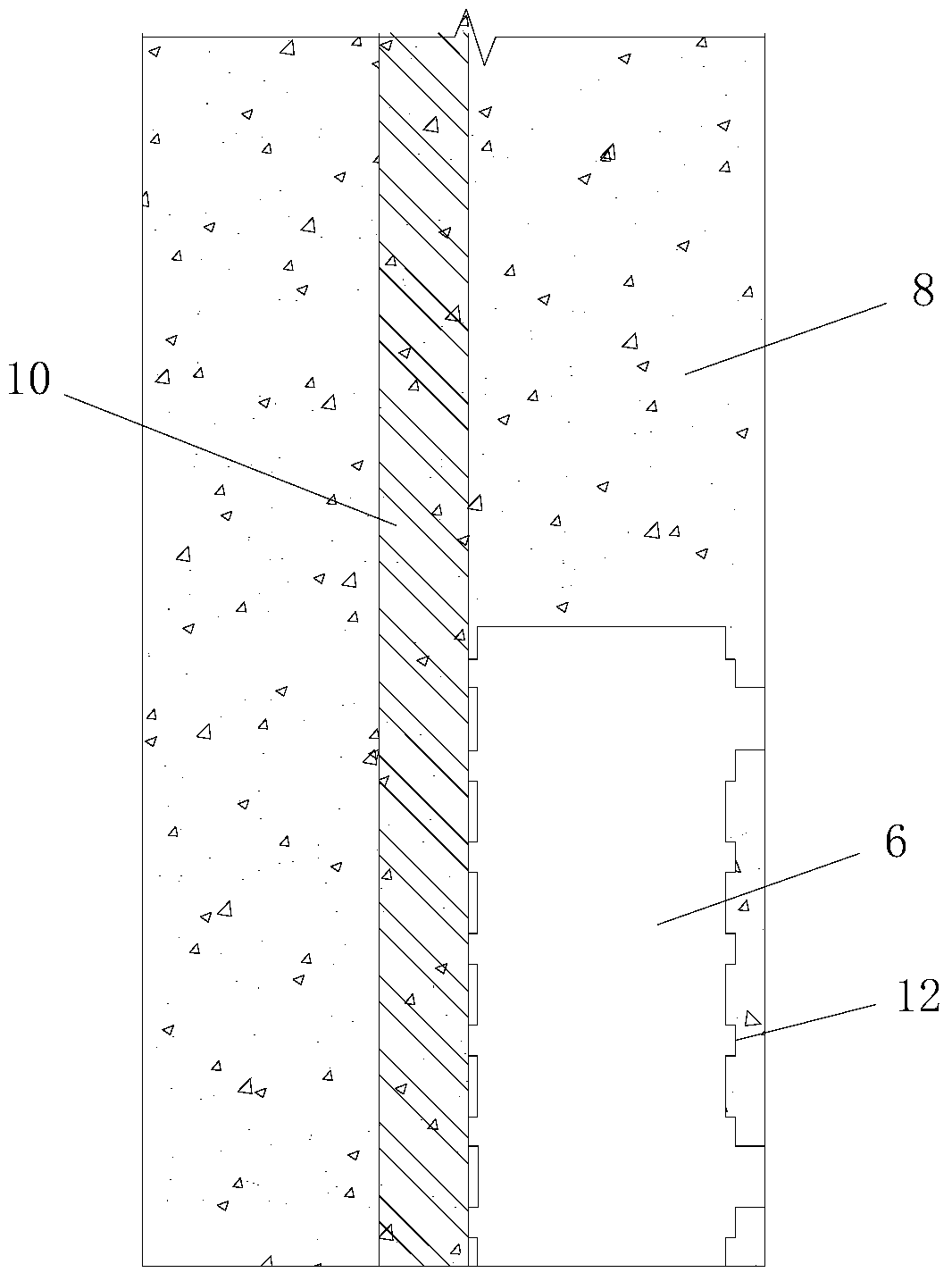

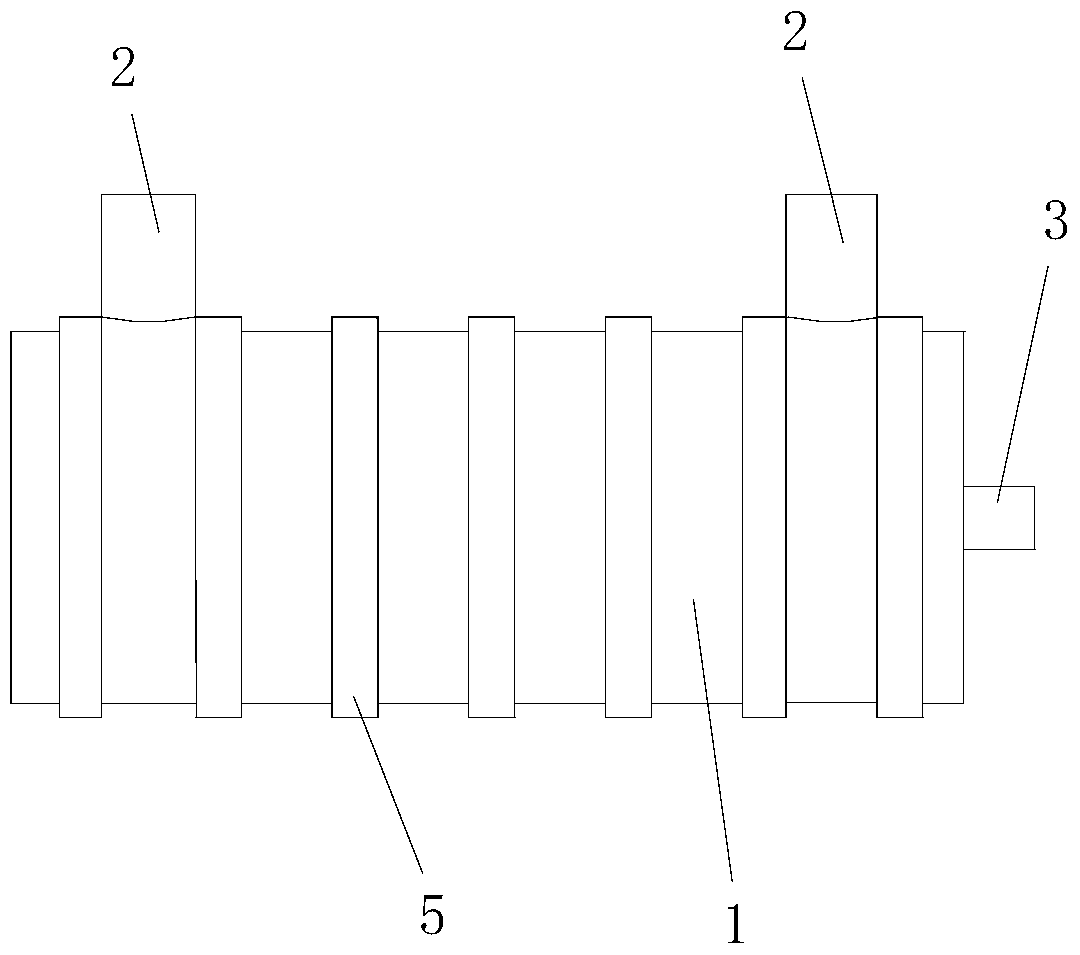

[0052] Such as figure 1 The illustrated prefabricated concrete component anchorage connection structure includes a first prefabricated concrete component 7 and a second prefabricated concrete component 8 above the first prefabricated concrete component 7; figure 2 , the bottom of the second prefabricated concrete member 8 is provided with a steel bar anchoring reserved hole 6 for anchoring the first steel bar 9, and the first steel bar 9 is a pre-embedded steel bar embedded in the first prefabricated concrete member 7 and its The upper end protrudes to the outside of the first precast concrete member 7, and the upper end of the first steel bar 9 is inserted into the reserved hole 6 for anchoring the steel bar from bottom to top. A grouting structure 11 formed by grouting material is provided in the cavity between the steel bar anchoring reserved hole 6 and the first steel bar 9, and the first steel bar 9 is fastened and fixed to the steel bar anchoring reserved hole through t...

Embodiment 2

[0090] In this example, if Figure 7 As shown, the difference between the steel bar anchoring connection structure used and the embodiment 1 is that: the steel bar anchoring reserved hole 6 is provided with a spiral bar 13 , and the spiral bar 13 is coaxially sleeved on the first steel bar 9 .

[0091] In this embodiment, the structure of the remaining part of the steel bar anchorage connection structure is the same as that in Embodiment 1.

[0092] In this example, if Figure 8 As shown, the steel bar anchoring connection method adopted is different from that of Example 1 in that: before the second prefabricated concrete member is hoisted and the first steel bar is inserted in step 2, the spiral bar 13 is first set on the first steel bar 9; The hoisting equipment lifts the second precast concrete member 8 above the first precast concrete member 7, and lowers the second precast concrete member 8, so that the first steel bar 9 and the spiral bar 13 set outside it are inserted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com