A kind of sodium valproate compound

A technology of sodium valproate and compounds, applied in the separation/purification of carboxylic acid compounds, active ingredients of anhydrides/acids/halides, organic chemistry, etc., can solve problems such as medical accidents, patient danger, and increased impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

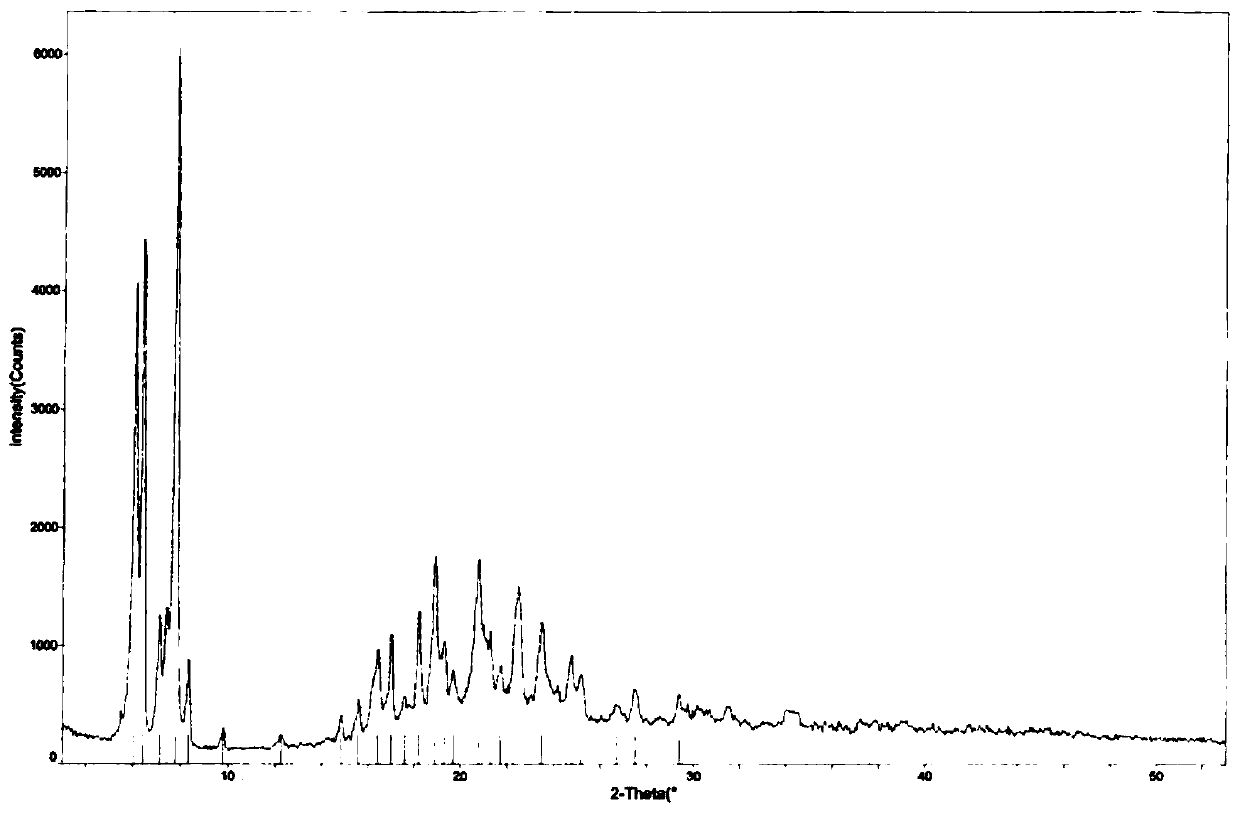

Image

Examples

Embodiment 1

[0040] Sodium valproate of the present invention is prepared according to the following steps:

[0041] A, pretreatment: get sodium valproate crude product 3kg, be dissolved in 15L water for injection, after fully dissolving, add the activated carbon of 0.1%g / mL, heat and stir, activated carbon is filtered and removed, obtain sodium valproate clarified aqueous solution, Then pass through a 0.22μm microporous membrane, and then pack in vials;

[0042] B. Pre-freezing: Put all the bottles in step (1) into a freeze dryer at -18°C, keep for 2 hours, continue to cool down to -45°C, and keep for 2 hours;

[0043] C. Freeze-drying: Continue vacuuming to 20Pa, then gradually increase the temperature of the plate to -30°C, and keep for 40 hours; then gradually increase the temperature of the plate to 0°C, and keep for 15 hours; then continue to increase the temperature of the plate to 15°C, keep for 5 hours;

[0044] D. Secondary drying: Continue vacuuming to 20Pa, then gradually inc...

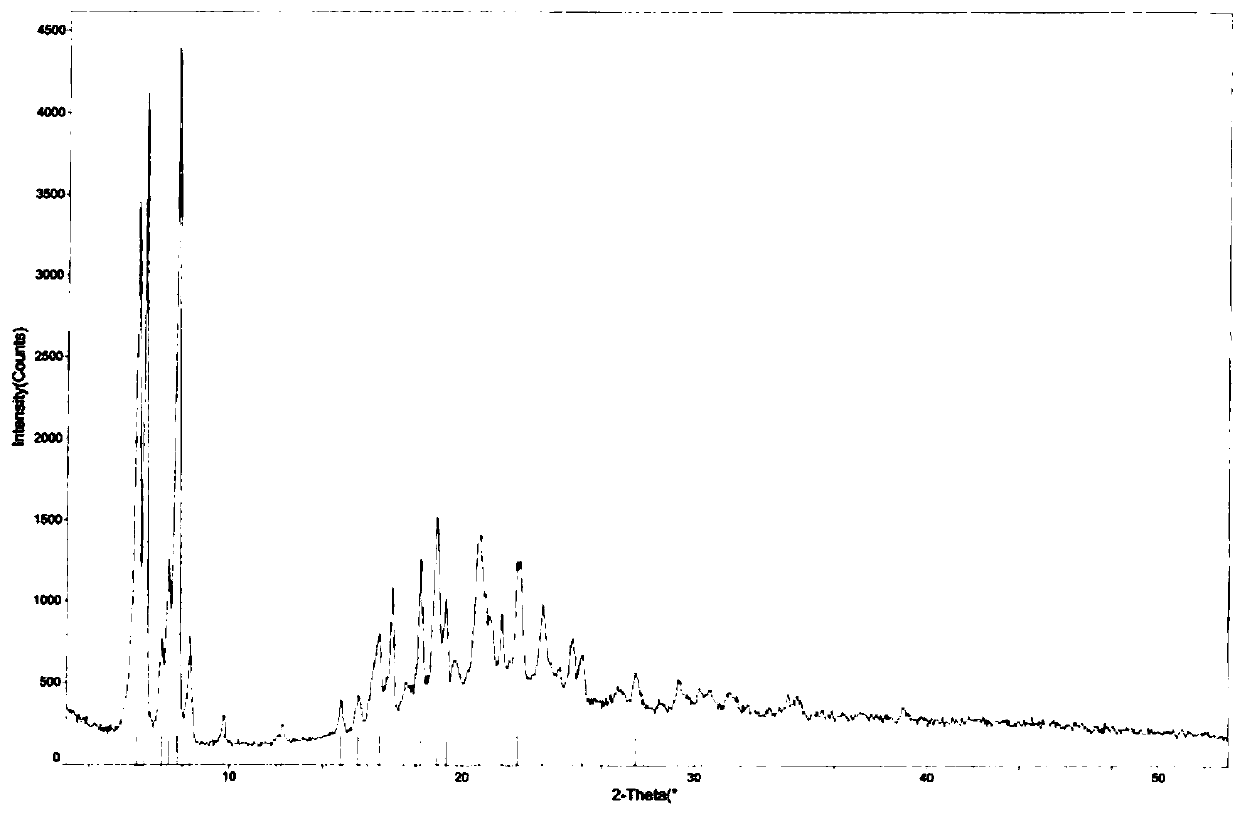

Embodiment 2

[0046] Sodium valproate of the present invention is prepared according to the following steps:

[0047] A, pretreatment: get sodium valproate crude product 3kg, be dissolved in 17L water for injection, after treating fully dissolving, add the gac of 0.1%g / mL, heat and stir, gac is filtered and removed, get sodium valproate clarified aqueous solution, Then pass through a 0.22μm microporous membrane, and then pack in vials;

[0048] B. Pre-freezing: Put all the bottles in step (1) into a freeze dryer at -10°C, keep for 1 hour, continue to cool down to -40°C, and keep for 3 hours;

[0049] C. Freeze-drying: Continue vacuuming to 20Pa, then gradually increase the temperature of the plate layer to -10°C, and keep for 20 hours; then gradually increase the temperature of the plate layer to -5°C, and keep for 10 hours; then continue to increase the temperature of the plate layer to 10°C for 2 hours;

[0050] D. Secondary drying: Continue vacuuming to 20Pa, then gradually increase th...

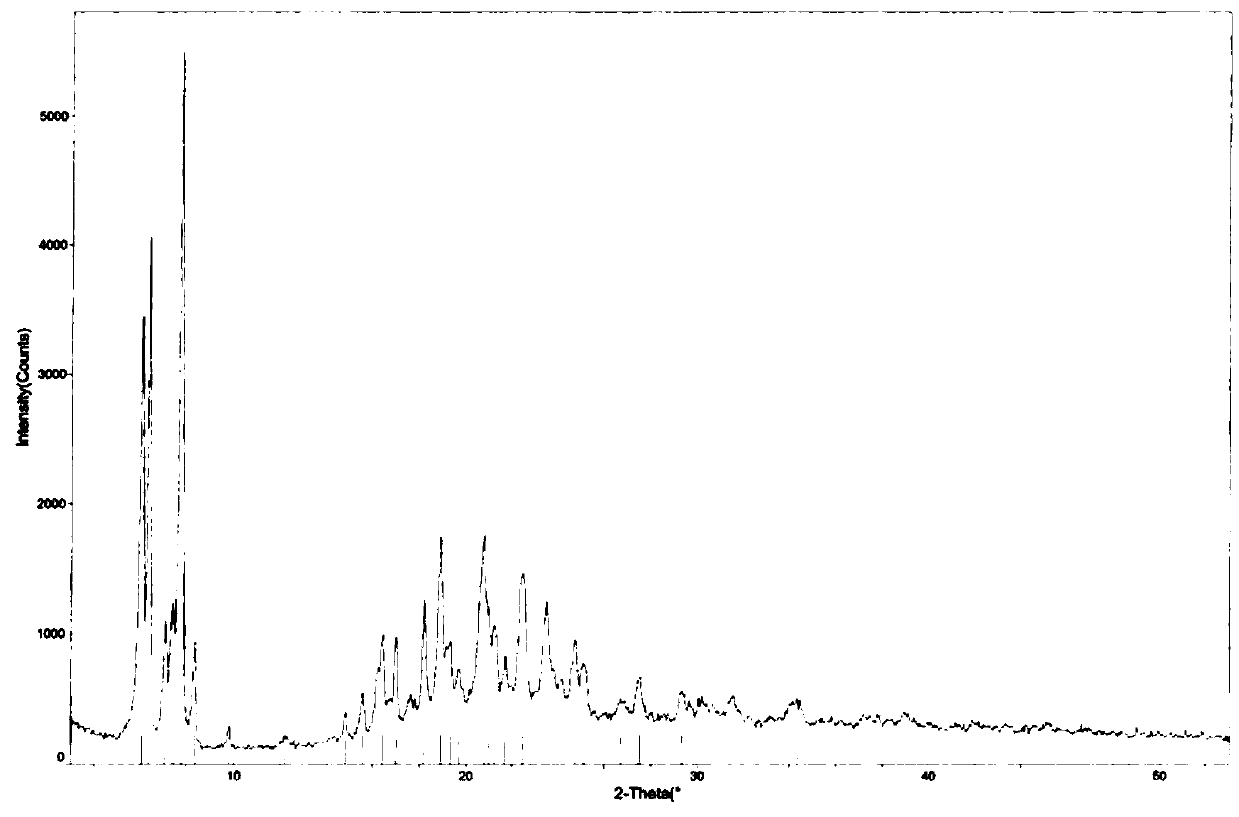

Embodiment 3

[0052] Sodium valproate of the present invention is prepared according to the following steps:

[0053] A, pretreatment: get sodium valproate crude product 3kg, be dissolved in 20L water for injection, after fully dissolving, add the activated carbon of 0.1%g / mL, heat and stir, activated carbon is filtered and removed, obtain sodium valproate clarified aqueous solution, Then pass through a 0.22μm microporous membrane, and then pack in vials;

[0054] B. Pre-freezing: Put all the bottles in step (1) into a freeze dryer at -50°C and keep for 3 hours;

[0055] C. Freeze-drying: Continue to vacuumize to 20Pa, then gradually increase the temperature of the plate to -25°C for 30 hours; then gradually increase the temperature of the plate to -10°C and keep for 3 hours; then continue to increase the temperature of the plate to 5°C, keep for 6 hours;

[0056] D. Secondary drying: Continue vacuuming to 20Pa, then gradually increase the temperature of the plate layer to 35°C, and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com