Biogas slurry pretreatment device

A pretreatment device and biogas slurry technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor biodegradability of biogas slurry, long anaerobic residence time, separation Technically difficult solid/liquid separation and other issues, to achieve the effect that is conducive to the subsequent advanced treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

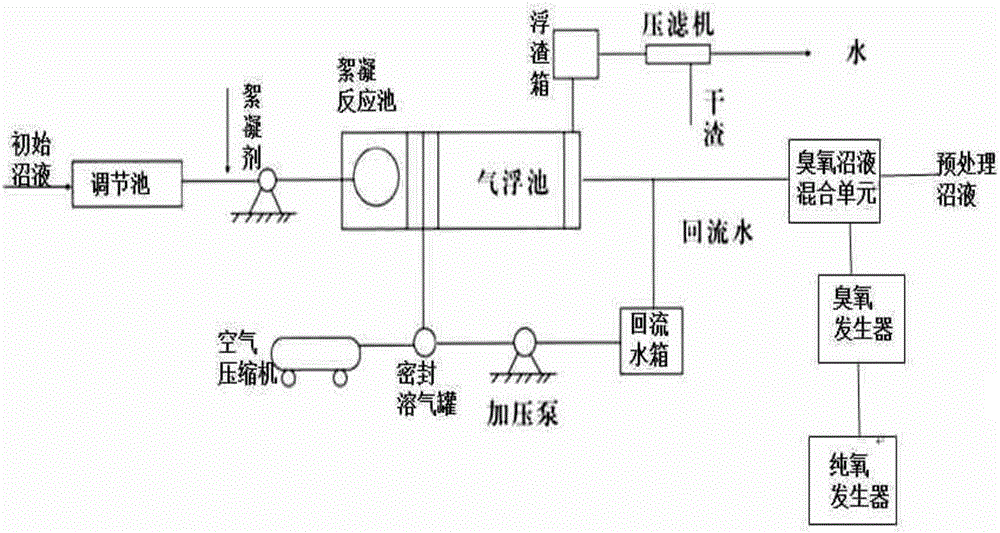

[0019] figure 1 It is a structural schematic diagram of the biogas slurry pretreatment device of this embodiment.

[0020] The biogas slurry pretreatment device of the present invention includes a flocculation sedimentation unit, an air flotation unit and an ozonation unit connected in sequence. The flocculation and sedimentation unit is used to flocculate and settle the biogas slurry to remove heavy metal ions; the air flotation unit is connected to the flocculation and sedimentation unit to perform air flotation treatment on the biogas slurry after flocculation and precipitation, and remove the slick oil in the biogas slurry; The ozonation unit is connected with the air flotation unit, and is used to treat the biogas slurry after the air flotation treatment, and remove organic macromolecules that damage the membrane.

[0021] The floc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com