Hand holding type combined fork arm carrier

A walk-behind, truck technology, applied in the direction of lifting devices, etc., can solve the problems of low work efficiency, forklifts cannot forklift and transfer goods, and takes a long time, and achieves the effect of improving work efficiency, shortening the body, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

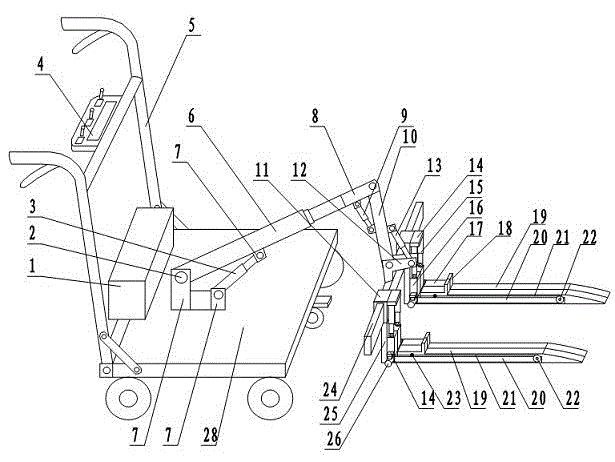

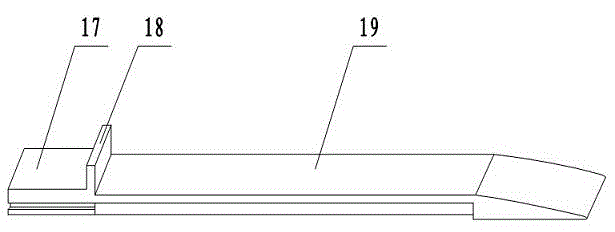

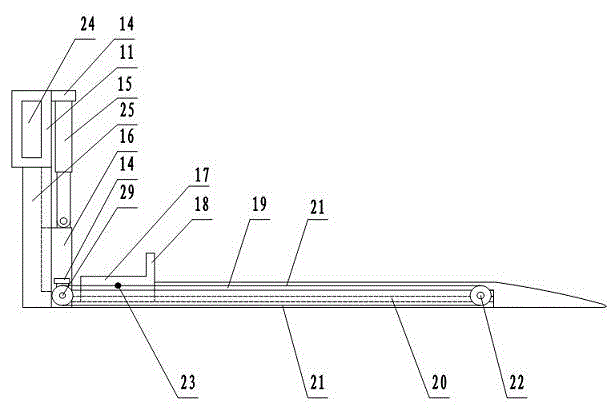

[0028] combine figure 1 , figure 2 , image 3 Describe the structure of each part of the walk-behind combined yoke truck.

[0029] figure 1In the figure, is the overall structure diagram of the walk-behind combination yoke truck. A hinge seat 7 is installed on the vehicle frame 28 . The lower end of the main arm 6 is hinged on the hinge seat 7 with the pivot pin 2 . The main boom 6 is a telescopic boom with the same structure as the truck crane. The front end of the last stage arm of the main arm 6 is connected and fixed with a connecting section 8 . The rear end of boom 10 is hinged at the end of connecting section 8 with pivot pin 2 . The front end of the boom 10 is hinged to the cross frame seat 12 . The horizontal frame seat 12 is integrated with the horizontal frame 24. One end of the main arm oil cylinder 3 is hinged on the hinge seat 7 on the vehicle frame 28, and the other end is hinged on the main arm. One end of the boom oil cylinder 9 is hinged on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com