Combination wishbone light vehicle

A fork arm and light technology, which is applied in the field of combined fork arm light vehicles, can solve the problems that forklifts cannot fork load and transfer goods, take a long time, and have low work efficiency, and achieve the effects of short body, reduced labor intensity, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

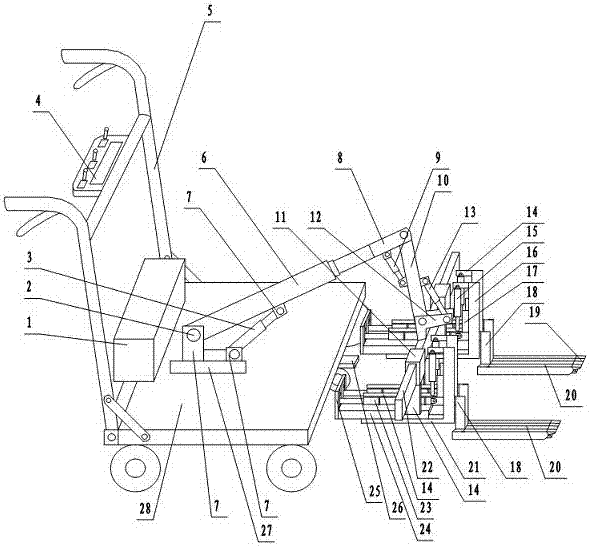

[0036] Accompanying drawing and following narration all are to push forward the common type of slide plate as example.

[0037] figure 1 In , the overall structure diagram of the light vehicle with combined wishbone arms. A turntable 27 is installed on the vehicle frame 28. Hinge seat 7 is installed on the rotating disk 27. The lower end of the main arm 6 is hinged on the hinge seat 7 with the pivot pin 2 . The main boom 6 is a telescopic boom with the same structure as the truck crane. The front end of the last stage arm of the main arm 6 is connected and fixed with a connecting section 8 . The rear end of boom 10 is hinged at the end of connecting section 8 with pivot pin 2 . The front end of the boom 10 is hinged to the cross frame seat 12 . The horizontal frame seat 12 is integrated with the horizontal frame 22 . One end of main arm oil cylinder 3 is hinged on the hinge seat 7 on the rotating disk 27, and the other end is hinged on the main arm. One end of the boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com