Cylindrical oil drum carrying device

A technology for handling devices and oil drums, which is applied in the direction of transportation and packaging, manual conveying devices, etc., can solve the problems of unstable positioning of oil drums, large volume of transport vehicles, and insufficient mobility and flexibility, and achieve fast and convenient clamping, small size, The effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

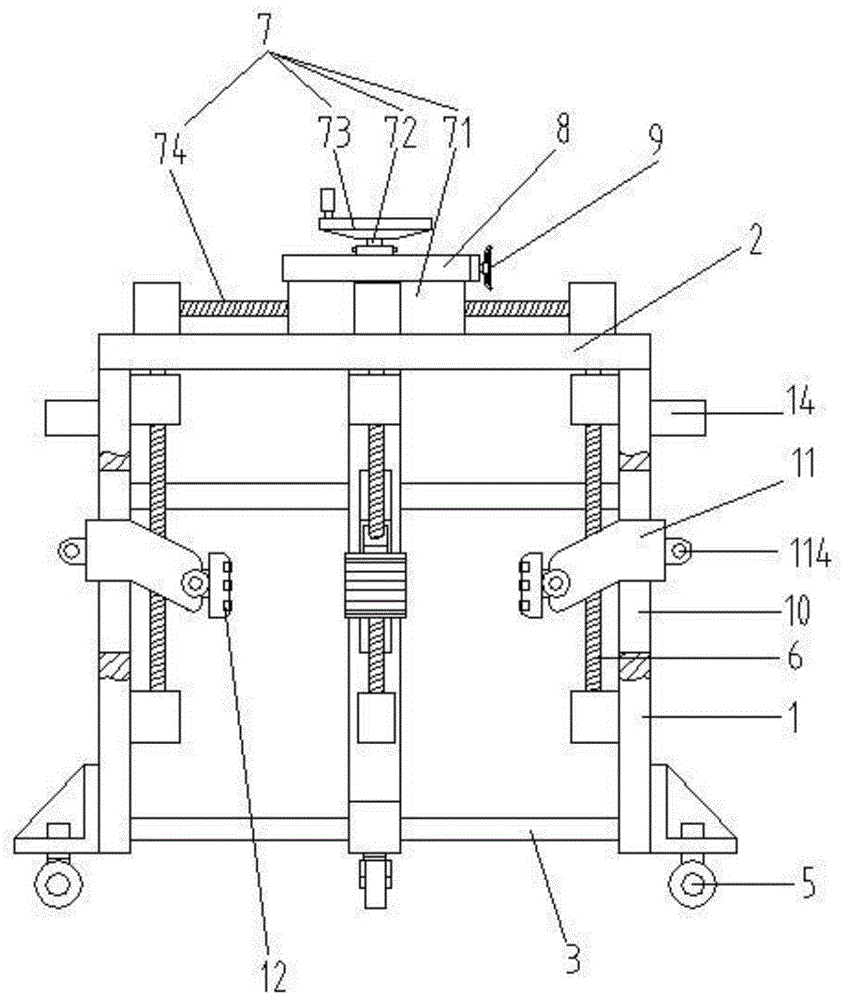

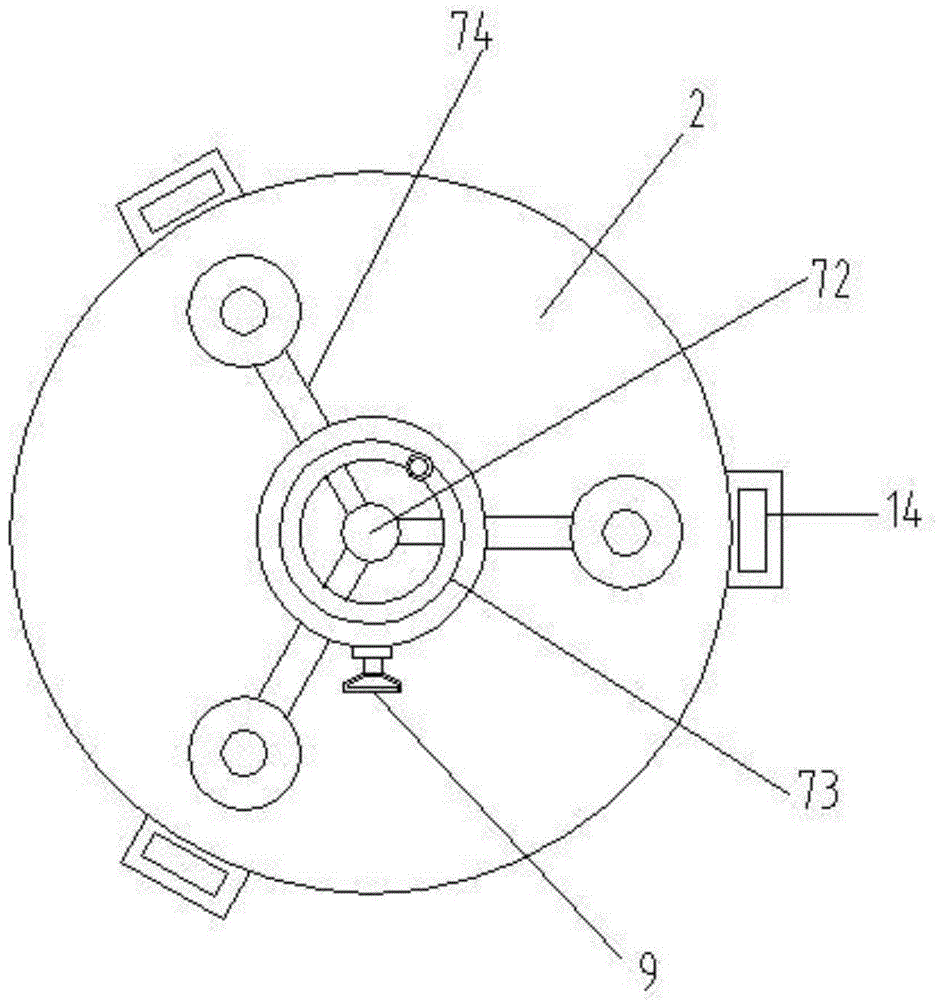

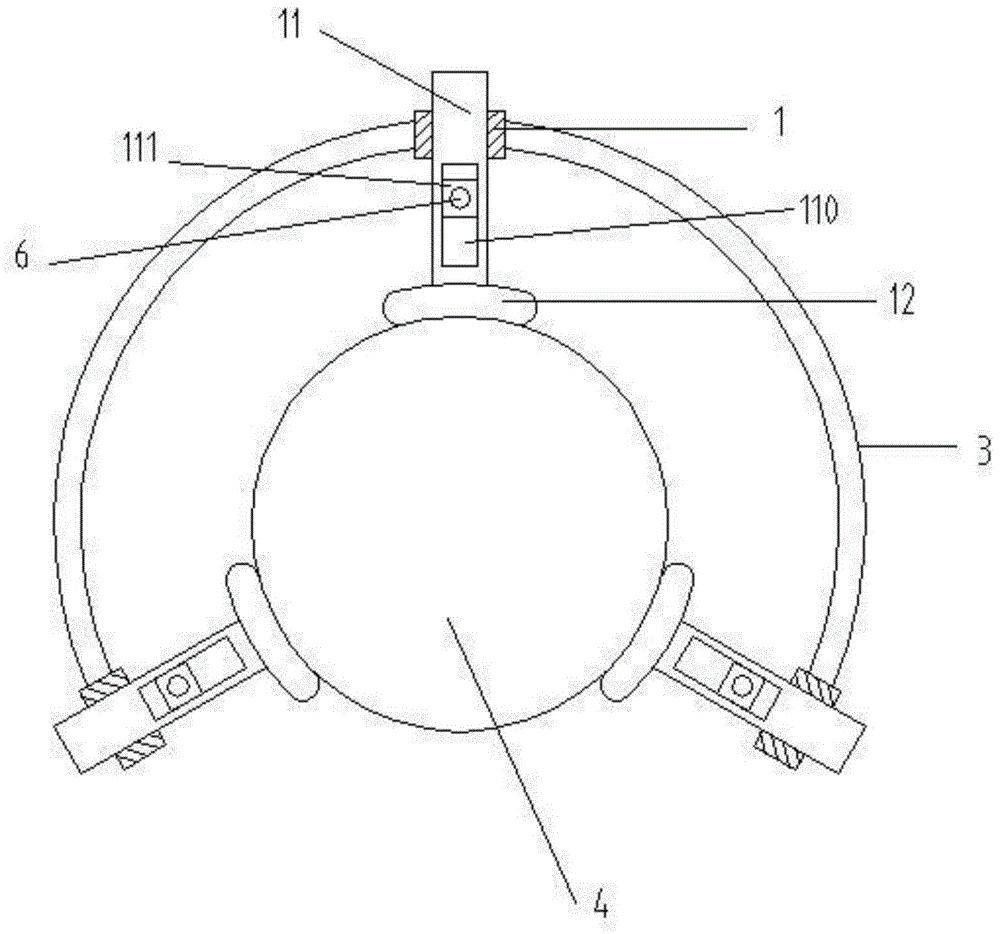

[0028] Such as figure 1 A columnar oil drum handling device shown includes three uprights 1 and a base plate 2 connecting the uprights. The base plate 2 is a horizontal circular plate, and the uprights 1 are vertically fixed at the edge of the lower side of the base plate, and there are connecting rods between the uprights. 3. There is no connecting rod installed between the two uprights, so that it can be directly inserted into the oil drum 4 from the side. When the diameter of the oil drum is large, it can also be directly covered from the top of the oil drum. There is a handle 14 on the outside of the upright 1 The lower end of the column 1 is provided with a bottom wheel 5, and the inner surface of each column is provided with a parallel lifting screw 6, and the upper side of the base plate 2 is used to drive a screw drive mechanism 7 for synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com