Miniaturized apple net sleeve automatic packing machine

An automatic packaging machine, apple technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of unstable packaging quality, low packaging efficiency, high labor cost, etc., and achieve the effect of reliable mechanism, high packaging efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

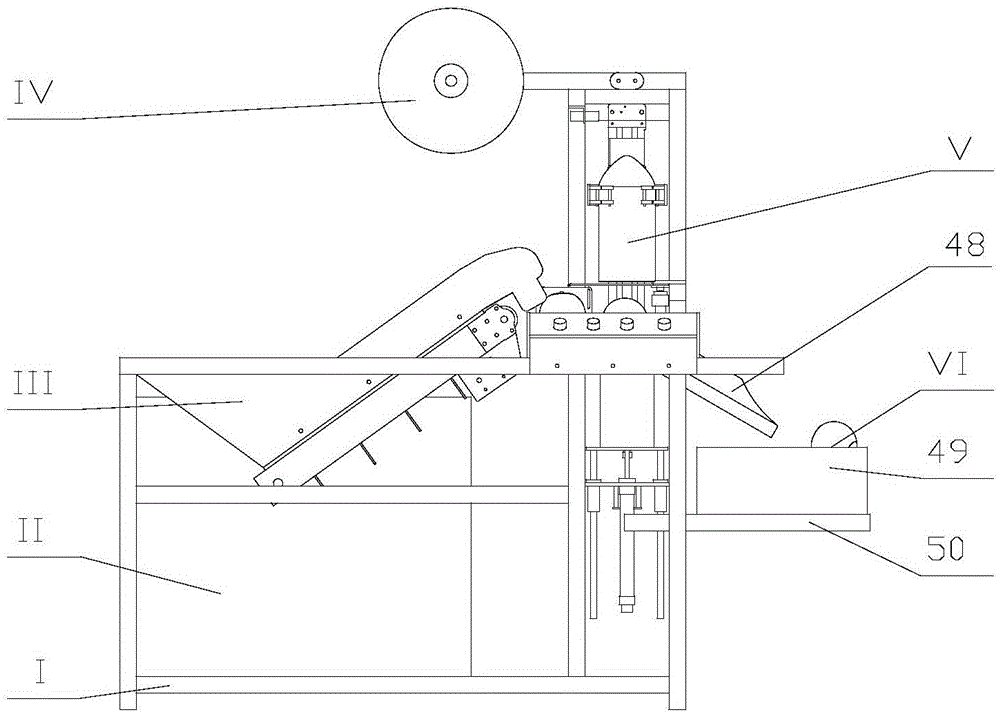

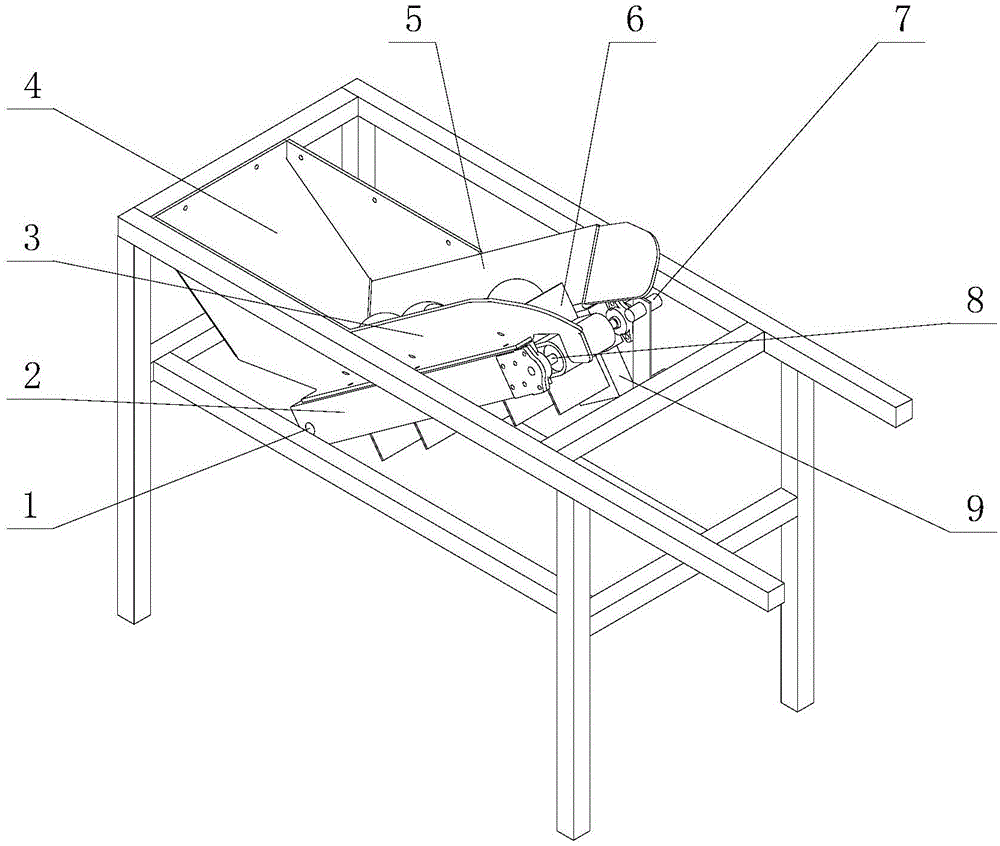

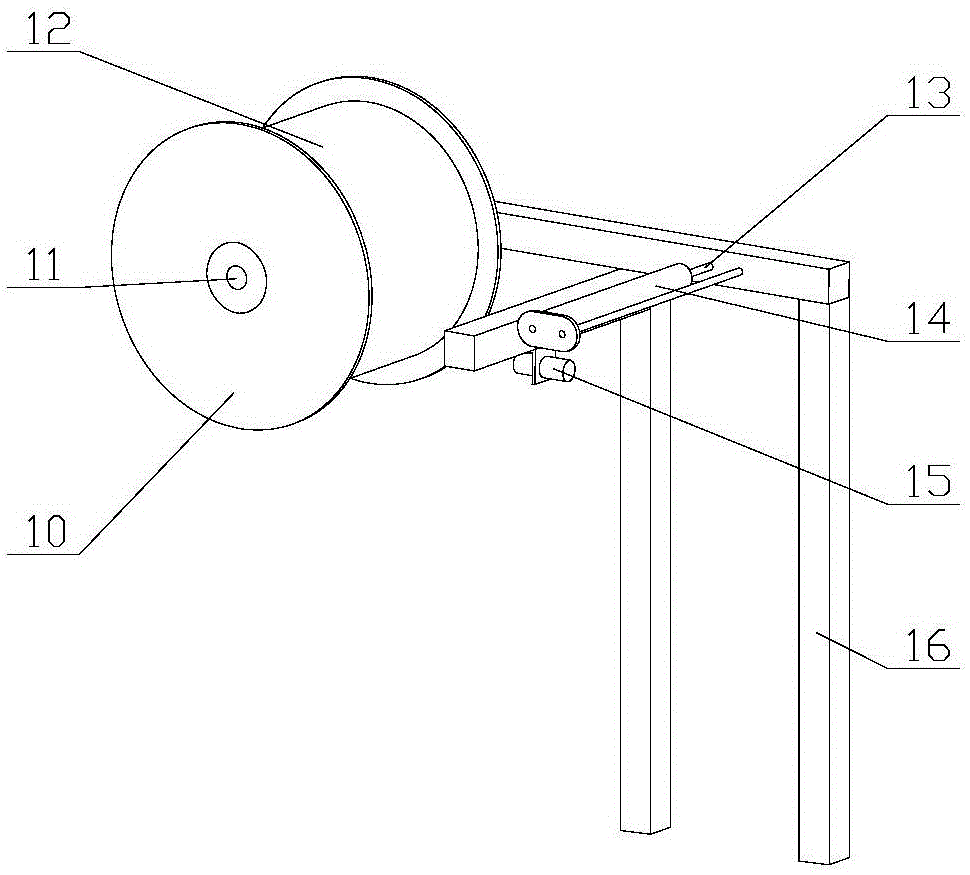

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The present embodiment small-sized apple net cover automatic packing machine mainly comprises frame I, electric control box II, apple feeding module III, net cover feeding module IV, cover net module V, finished product collection module VI, and frame I is used for installing For each module, assemble each module with different functions into a whole, install the finished product collection module VI on one side of the rack I, install the apple feeding module III and the netting module V on the rack I, and the discharge of the apple feeding module III Corresponds to one side of the network outlet of the network module V, and the other side of the network outlet of the network module V corresponds to the finished product collection module VI. The net cover feeding module IV is arranged above the net cover module V. The apple feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com