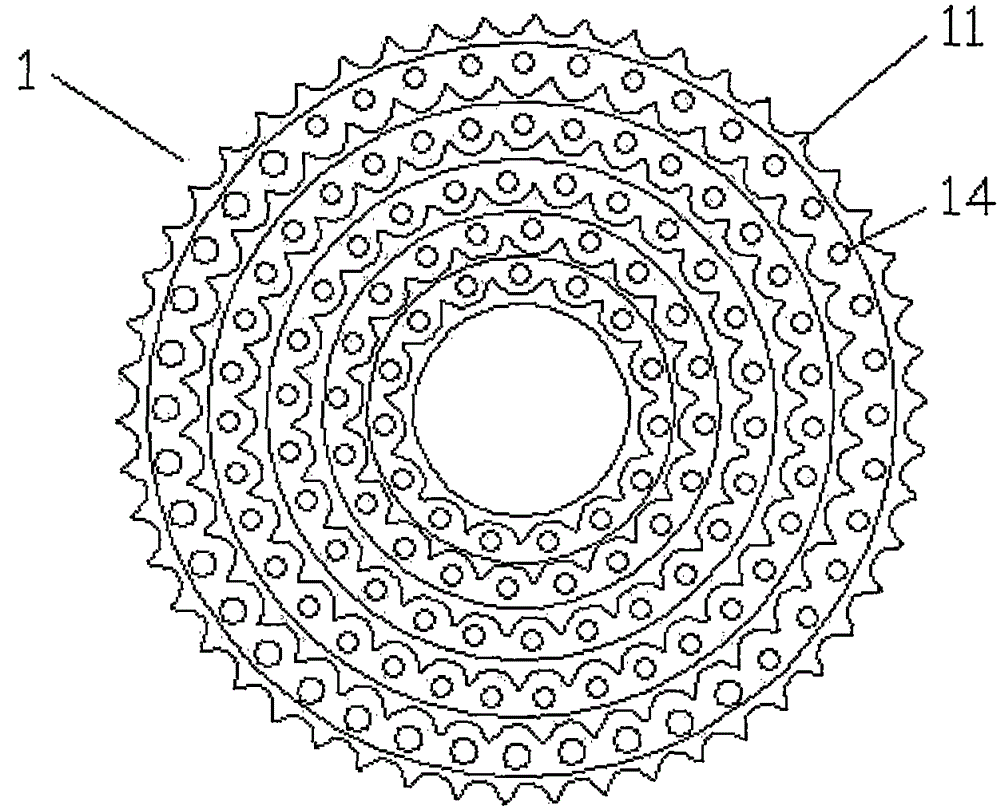

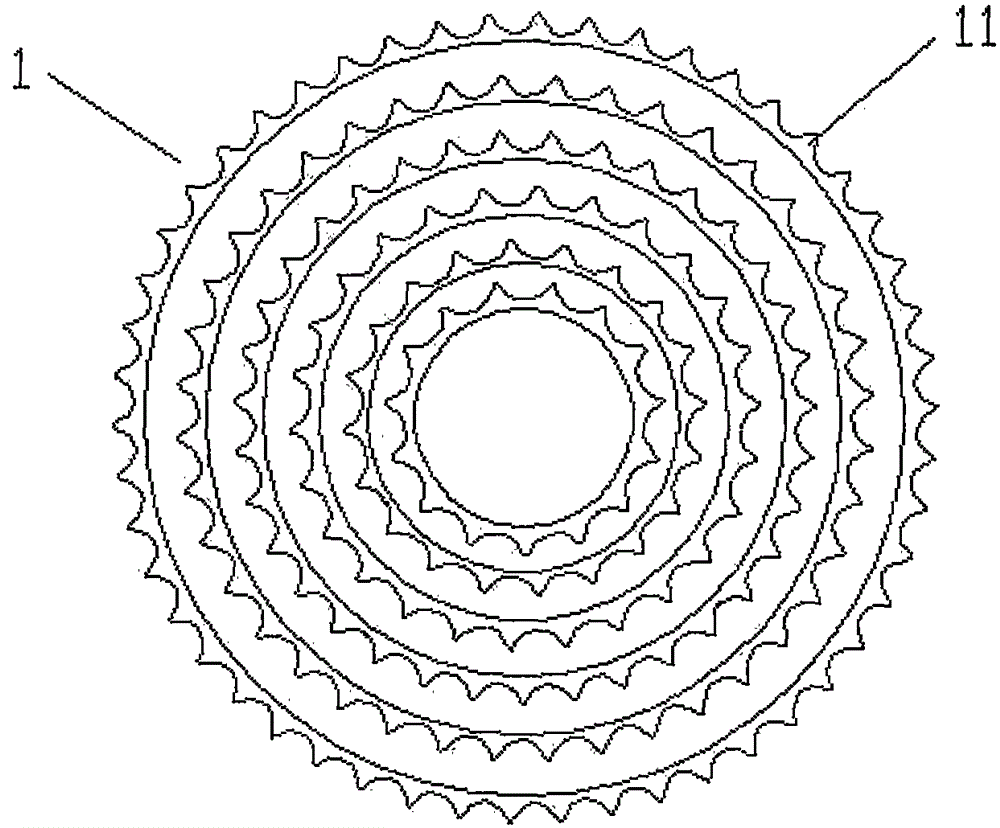

Light large-torque high-rigidity variable speed bicycle chain wheel assembly structure

A variable speed bicycle and sprocket assembly technology, which is applied to vehicle gearboxes, vehicle components, chain/belt transmissions, etc., can solve the problems of low rigidity of the teeth and large structural quality of the sprocket, and achieve lightweight and strong structure. Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

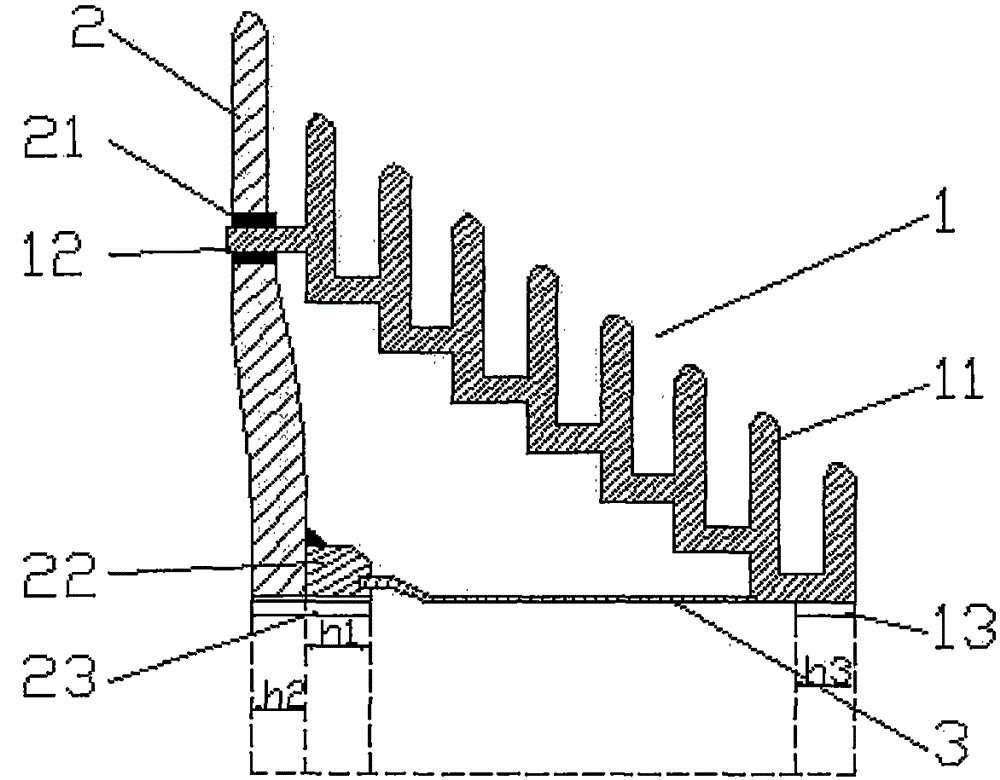

[0031] Embodiment 2: The difference from Embodiment 1 is that the spline widening ring 22 is connected to the single-piece tooth 2 by riveting; the thickness t of the single-piece tooth 2 is 3mm, and the width of the spline widening ring 22 is h1 is 6 mm, and the thickness a of the spline widening ring 22 is 8 mm; the joints of the integral tower wheel 1 and the single-piece tooth 2 with the support tube 3 are fabricated connections;

[0032] The product manufactured through the implementation method of Example 2, the entire sprocket weighed 213g after assembly, and then tested for a long time, with a loading torque of 100N*m to 250N*m, multiple speed changes were rapid and smooth, and there was no abnormality in continuous operation of 20,000km; The sprocket produced in this embodiment can maintain a good level of structural strength, rigidity and large torque transmission, and its mass is about 160g smaller than the sprocket of the traditional structure.

Embodiment 3

[0033] Embodiment 3: The difference from Embodiment 1 is that the integral tower wheel 1 is welded to the single-piece tooth at the connecting convex tooth part; the thickness t of the single-piece tooth 2 is 2.5mm, and the width of the spline widening ring 22 h1 is 8 mm, and the thickness a of the spline widening ring 22 is 4 mm.

[0034] The product manufactured through the implementation method of Example 3, after the assembly of the entire sprocket, weighed 202g, and then tested for a long time, with a loading torque of 100N*m to 250N*m, multiple speed changes were rapid and smooth, and there was no abnormality in continuous operation of 20,000km; The sprocket produced in this embodiment can maintain a good level of structural strength, rigidity and large torque transmission, and its mass is about 170g smaller than the sprocket of the traditional structure.

Embodiment 4

[0035] Embodiment 4: The difference from Embodiment 2 is that the connection between the spline widening ring and the single tooth is welding, the thickness t of the single tooth 2 is 2.5mm, and the width h1 of the spline widening ring 22 is 10mm, and the thickness a of the spline widening ring 22 is 5mm.

[0036] For the product manufactured through the implementation of Example 4, the entire sprocket weighed 215g after assembly, and then tested for a long time, with a loading torque of 100N*m to 280N*m, multiple speed changes were rapid and smooth, and there was no abnormality in continuous operation of 20,000km; The sprocket produced in this embodiment can maintain a good level of structural strength, rigidity and large torque transmission, and its mass is about 160g smaller than the sprocket of the traditional structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com