High-speed connecting-rod press with integrated strut

A technology of integral pillars and presses, applied in the direction of presses, manufacturing tools, etc., can solve the problems of pillar deformation, complex dimensional chain, and incorrect position of supporting beams, etc., and achieve the effect of reducing installation difficulty and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

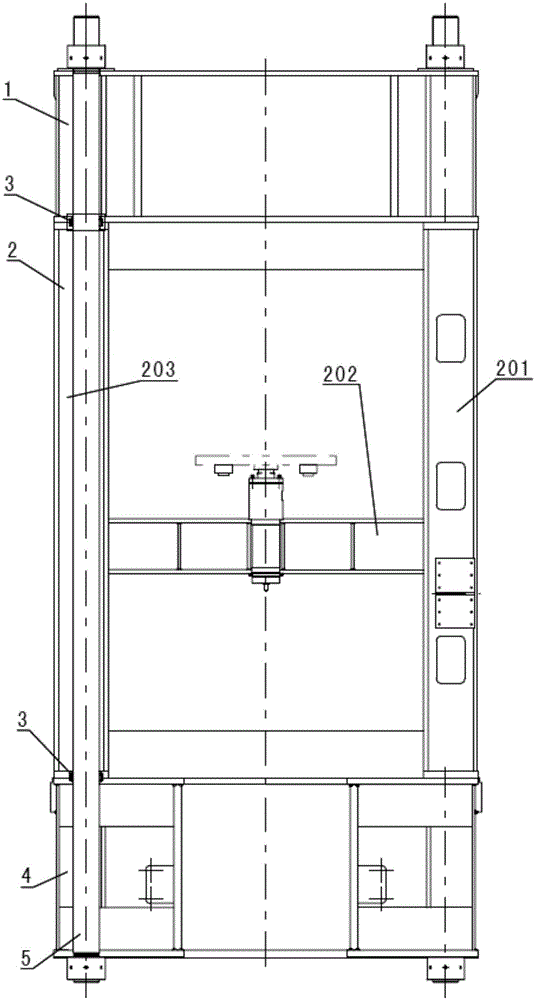

[0014] Such as figure 1 as shown,

[0015] A high-speed connecting rod press with an integral pillar, including an upper beam 1, a lower beam 4, and an integral pillar. The integral pillar is composed of two front pillars 201, two rear pillars 203, and a supporting beam 202. The supporting beam is welded Connect the front pillar and the rear pillar, the pillar is equipped with a tie rod 5, between the front pillar and the upper beam, between the front pillar and the lower beam, between the rear pillar and the upper beam, and between the rear pillar and the lower beam. The ring is positioned by the positioning ring 3.

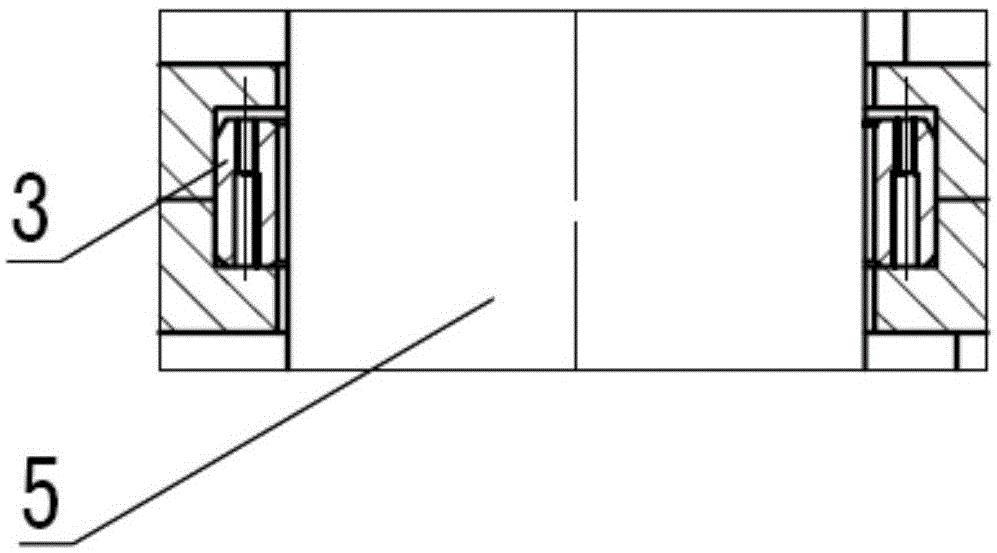

[0016] Such as figure 2 As shown, the positioning ring is responsible for the positioning between the upper and lower beams and the front and rear pillars, wherein the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com