a feeding mechanism

A blanking and grasping technology, applied in metal processing, etc., can solve problems affecting production efficiency, high cost of mechanical arms, troublesome software programming, etc., and achieve high processing efficiency, compact processing procedures, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

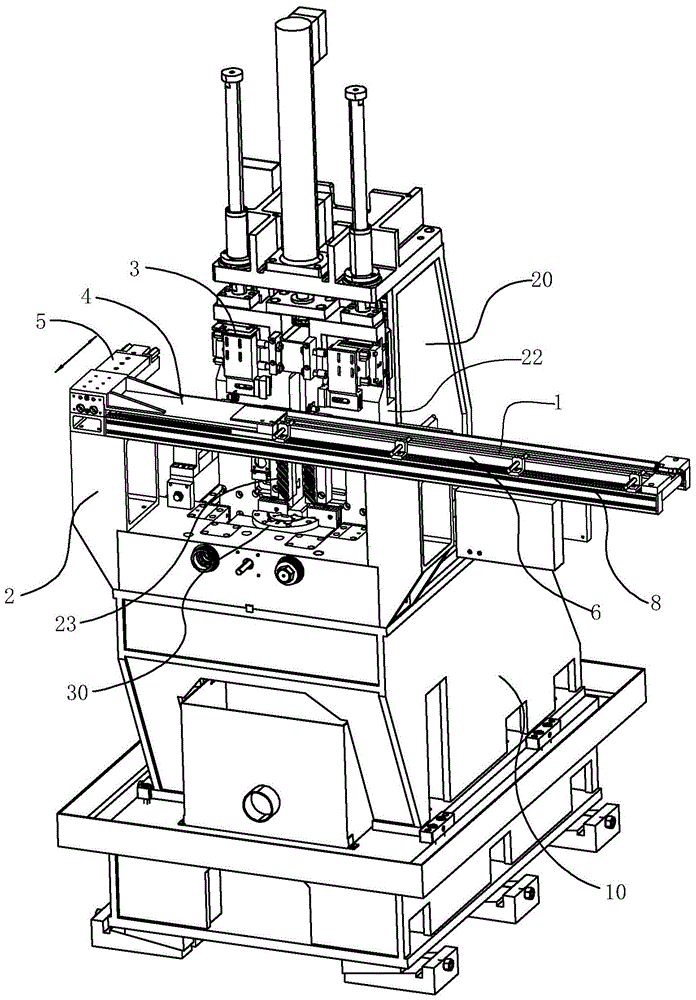

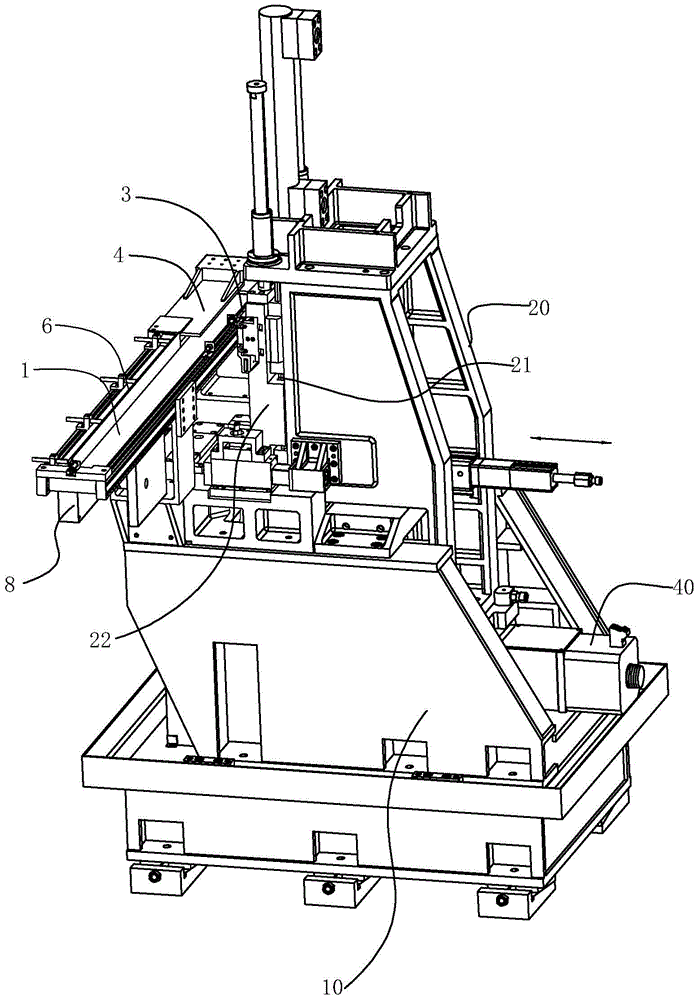

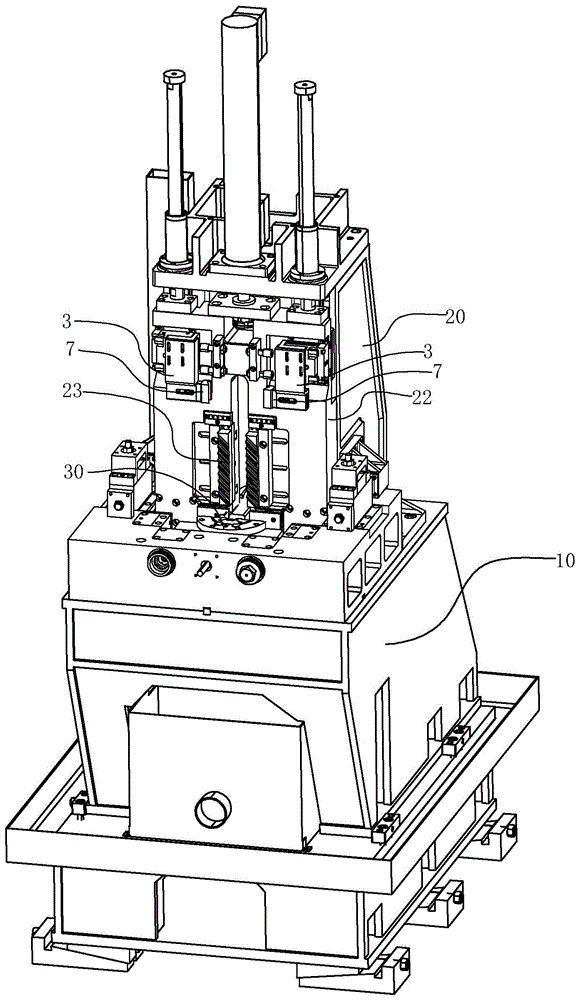

[0016] Such as Figure 1-4 Shown is a schematic diagram of the blanking mechanism and the broaching bed of the embodiment of the present invention. The broaching machine comprises a base 10 and a bed 20 arranged vertically on the base 10 , and a clamp 30 is arranged under the front side of the bed 20 to fix the workpiece to be processed. The bed 20 can move back and forth along the base 10 , close to the clamp 30 or away from the clamp 30 . A drive mechanism 40 is fixed on the rear side of the bed 20 to drive the bed 20 to move back and forth, and the drive mechanism 40 may be an air cylinder.

[0017] The bed 20 is provided with a guide rail 21 arranged up and down on the surface of the fixture 30, and a slide plate 22 positioned on the guide rail. The bed 20 is also provided with a transmission mechanism to drive the slide plate 22 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com