Metal laser selective melting forming double-piston controllable preheating powder cylinder

A technology of laser selective melting and dual pistons, which is applied in the field of additive manufacturing, can solve the problems of affecting the forming quality, uneven distribution of induced current, waste, etc., and achieve the effect of compact structure, overcoming errors and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

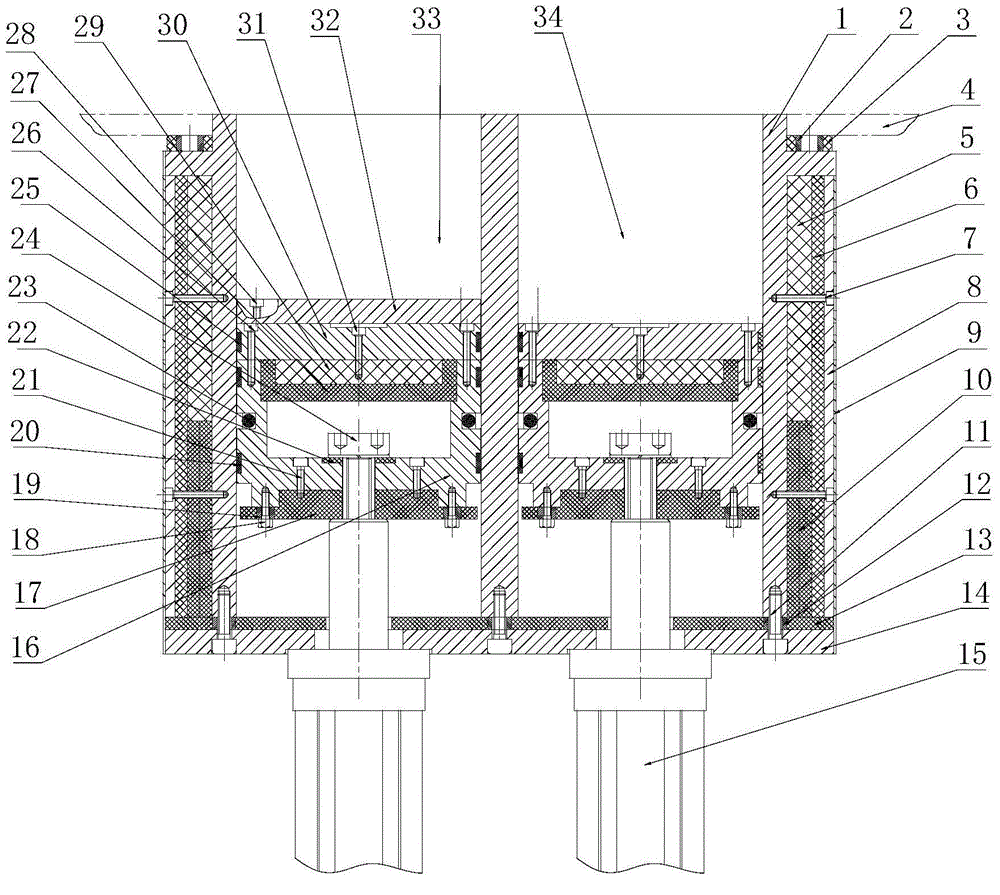

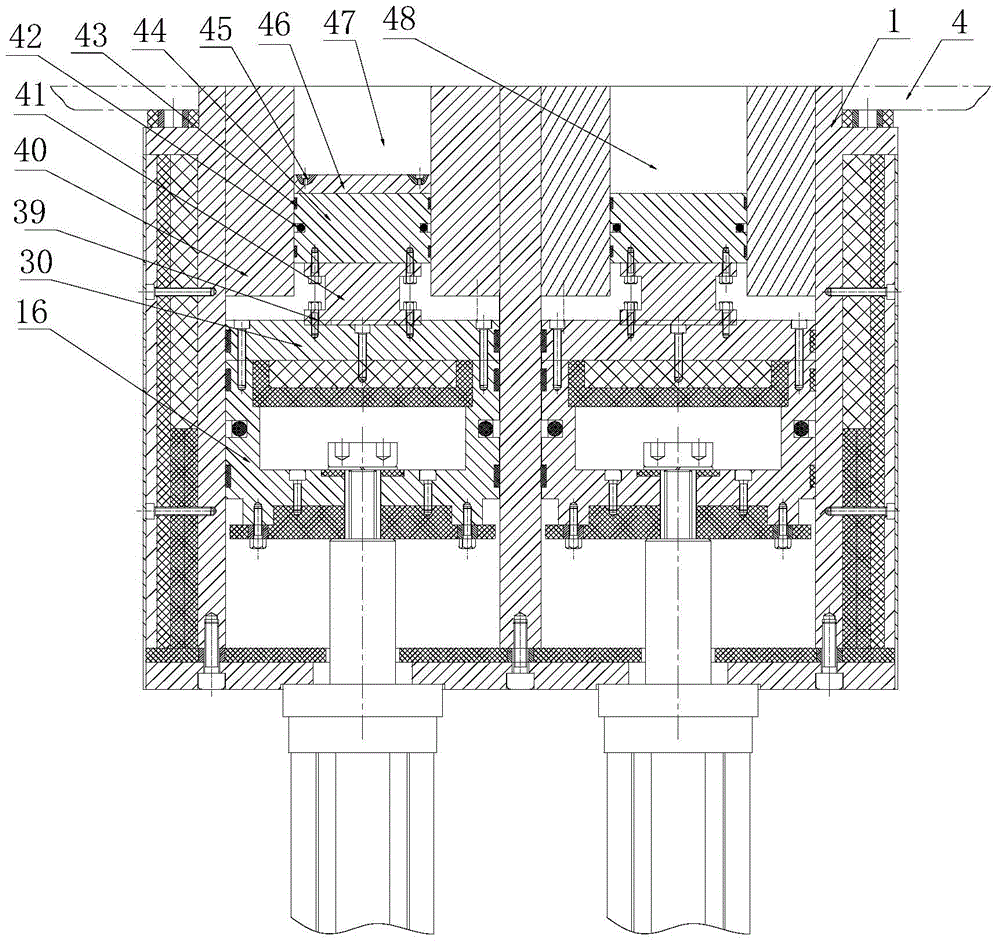

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

[0034] The invention relates to a dual-piston controllable preheating powder cylinder for metal laser selective melting and forming, which can work separately in two states of single-piston and double-piston.

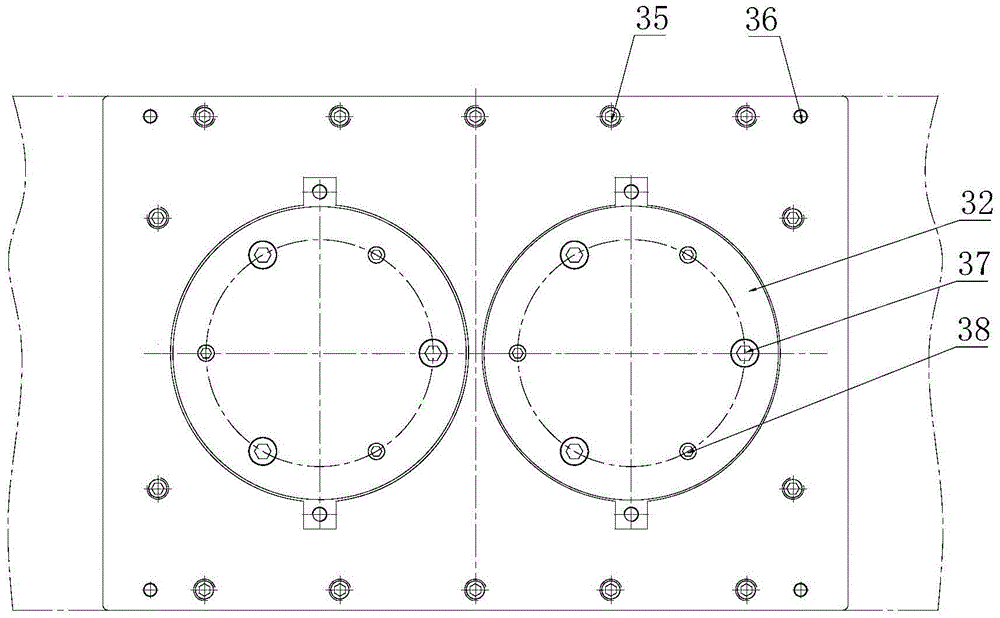

[0035] Such as figure 1 and figure 2 As shown, it is a structural diagram in a single-piston state, wherein the cylinder body 1 is fixed on the worktable 4 by fixing bolts 35 and pins 36, and a heat shield 3 is arranged between the cylinder body 1 and the worktable 4. There is a platen washer 2 at the position of the fixing bolt 35 on the platen heat insulating plate 3, and the platen washer 2 is used for the rigid and reliable combination of the surface of the cylinder body 1 and the surface of the working plate 4, so as to prevent the deformation of the platen heat insulating plate 3 from affecting the installation Accuracy, the platen heat shield 3 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com