Manufacturing method and device for mono-crystal-like turbofan aviation engine blade

A blade and single crystal technology, applied in the field of energy, can solve problems such as complex manufacturing process, high cost, and limited use, and achieve the effects of uniform distribution, avoiding oxidation, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

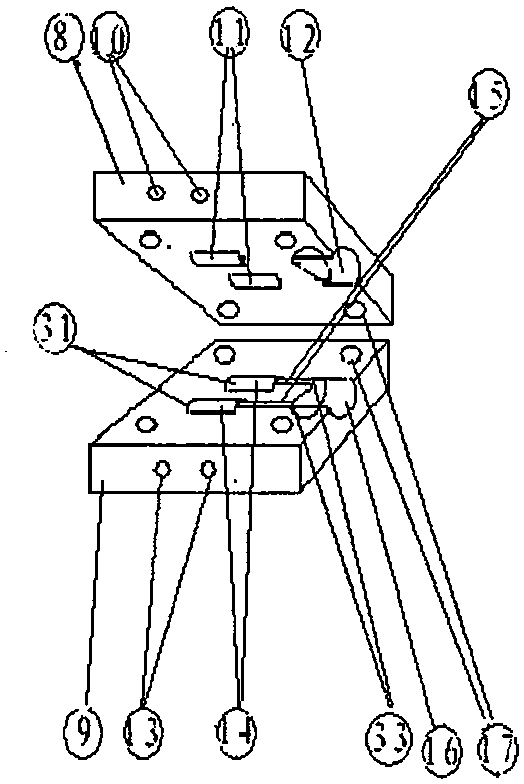

[0019] Preferred embodiment of the present invention is:

[0020] Using a high-power high-speed motor (19) as the power of the ultra-high-speed centrifuge, using the gearbox (20) to control the rotation speed of the vertical shaft (21), and gradually accelerating the centrifuge arm (18) to produce a centrifugal force (10g) that is more than ten times the gravity ). Rotating arm (18) long end is about 5 meters long, and metal mold (5) is installed at its end and is promptly fixed with centrifuge rotating arm (18) by bolt (17). The short end of the rotating arm (18) is about 2 meters long, and a high-frequency power supply (1) and a thermal oil temperature control box (6) are installed at its end as a counterweight, so that the rotating arm (18) is at a position where the vertical rotating shaft (21) is a fulcrum. state of horizontal balance. Vertically install the about 0.5 meter long pillar (24) below the long end of the pivoting arm (18), and the end of the pillar (24) is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com