Auxiliary process shaft used for spraying paint on wheels of railway vehicles

A rail vehicle and process axle technology, which is applied in the field of rail vehicle wheel painting auxiliary devices, can solve the problems of new wheels and standard axles affecting production progress, idle waste of paint booth resource equipment, and scrapping standard axles or new wheels. Reconstruction and optimization design, easy assembly and disassembly, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

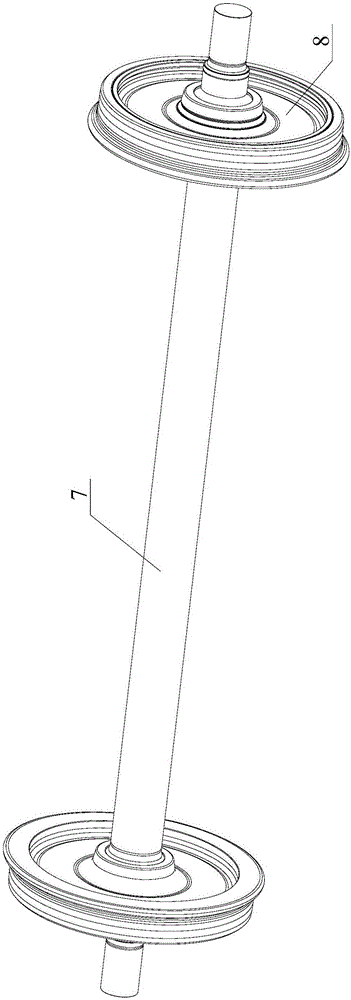

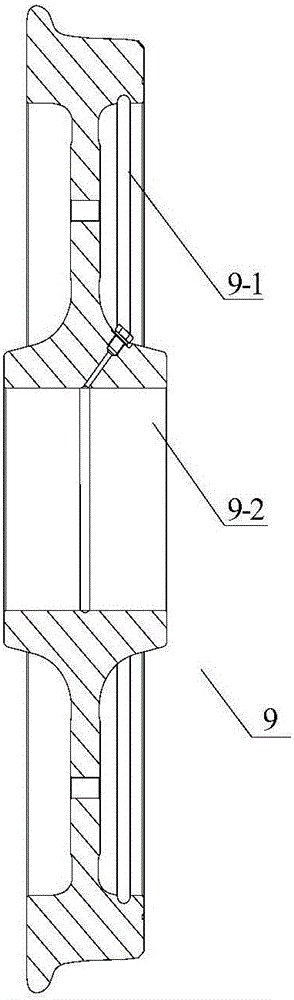

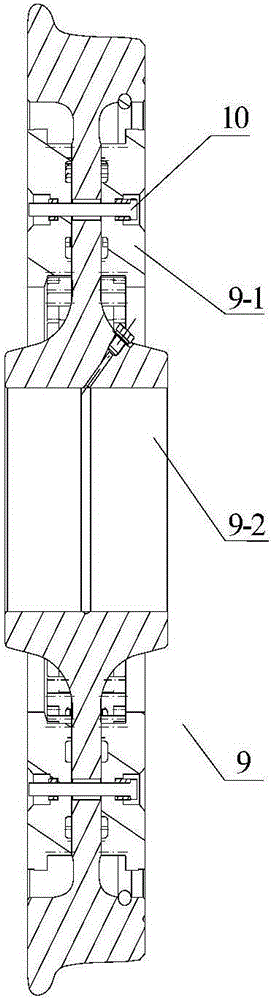

[0026] Such as Figure 4 to Figure 6 As shown, the auxiliary process shaft used for rail vehicle wheel painting in the present invention includes two wheel positioning mechanisms, and each wheel positioning mechanism includes a thick-walled steel pipe 1, a first tapered ferrule 2, a second tapered ferrule 3, The washer 4, the lock nut 5 and the lock pin 6 are provided with a radial pin through hole 11 on the side walls at both ends of the thick-walled steel pipe 1 respectively.

[0027] The first tapered ferrule 2 includes a first conical section 21, a threaded section 22 and a first conical section 23, the threaded section 22 is coaxially connected to the top end of the first conical section 21, and the first conical section 23 is connected to the first conical section 21 The bottom end of the first round platform 23 is coaxially connected, and the three ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com