A two-degree-of-freedom columnar ultrafiltration membrane pouring platform and its application method

An ultrafiltration membrane, degree of freedom technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of high physical fitness requirements of workers, large column membrane shells, increased work difficulty, etc., to improve the pass rate. , Easy to operate, save the effect of disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

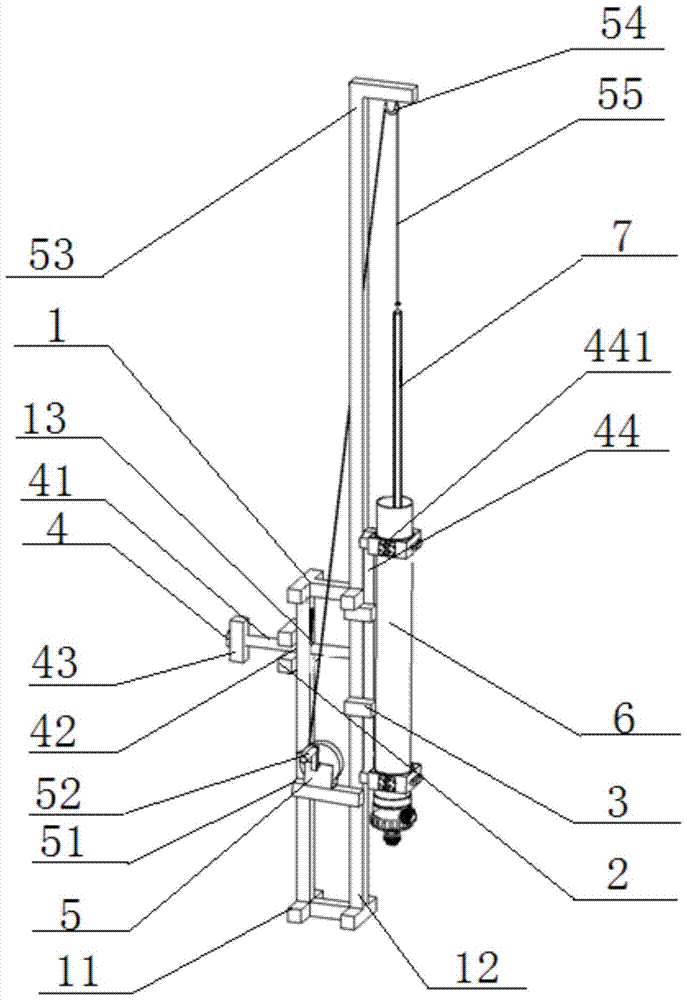

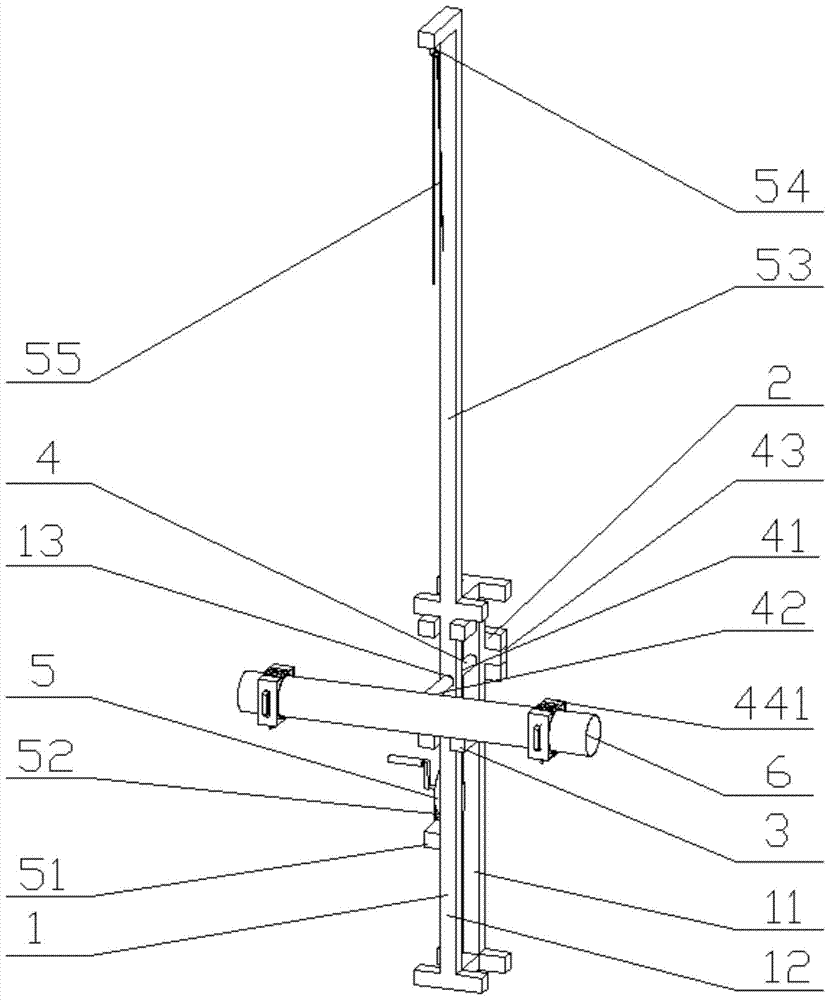

[0030] Two degrees of freedom means that the rotating device 4 of the present invention can perform axial linear motion along the rotating shaft 41 and perform circular motion around the rotating shaft 41 .

[0031] Such as figure 1 , 2 As shown, the present invention provides a two-degree-of-freedom column type ultrafiltration membrane pouring platform, including a frame 1 of a cuboid frame structure, a horizontal slot 2, a vertical slot 3, a rotating device 4 and a membrane tow lifting device 5, The frame 1 includes a rear support column 11 and a front support column 12 forming a rectangular parallelepiped frame structure, the horizontal draw-in slot 2 is arranged on the upper rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com