Device for drying grain by combine-harvester waste heat during harvesting process

A combine harvester and waste heat technology is applied in the field of drying grain devices, which can solve the problems of reducing the progress of drying equipment, consuming a large amount of energy, and consuming a huge amount of electricity, so as to achieve the effects of improving energy utilization, solving grain drying, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

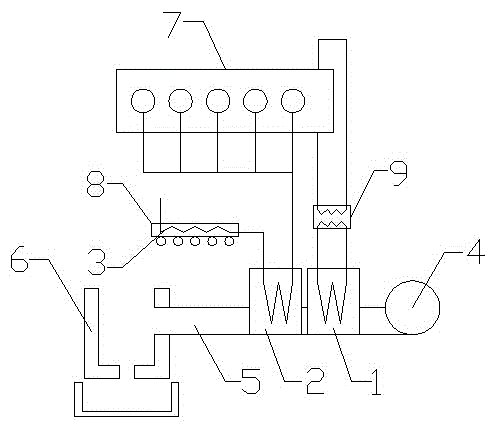

[0014] Such as figure 1 As shown, a device for drying grain during the harvesting process by utilizing waste heat of a combine harvester, the device is set on the combine harvester, including a first heat exchanger 1, a second heat exchanger 2, a third heat exchanger 3 and a first A fan 4, the air outlet of the first fan 4 is connected to the grain storage bin 6 of the combine harvester through the first air supply channel 5, and the first heat exchanger 1 and the second heat exchanger 2 are arranged in the first air supply channel 5 , the first heat exchanger 1 is connected to the cooling water tank of the combine harvester internal combustion engine 7, the inlet of the second heat exchanger 2 is connected to the exhaust pipe of the internal combustion engine 7, and the outlet of the second heat exchanger 2 is connected to the third heat exchanger 3 Connected, the third heat exchanger 3 is arranged on the conveyor belt 8 of the combine harvester. The exhaust gas of the i...

Embodiment 2

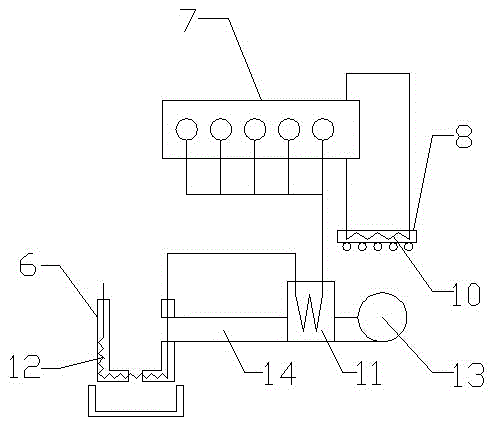

[0019] Such as figure 2 Shown, a kind of device that utilizes the waste heat of combine harvester to dry grain during harvesting process, this device is arranged on the combine harvester, comprises the 5th heat exchanger 10, the 6th heat exchanger 11, the 7th heat exchanger 12 and the 7th heat exchanger Two fans 13, the second fan 13 is connected with the grain storage bin 6 of the combine harvester through the second air supply passage 14, the sixth heat exchanger 11 is arranged in the second air supply passage 14, and the seventh heat exchanger 12 is arranged on the combined harvester. In the grain storage bin 6 of the harvester, the inlet of the sixth heat exchanger 11 is connected with the exhaust pipe of the internal combustion engine 7 of the combine harvester, the outlet of the sixth heat exchanger 11 is connected with the inlet of the seventh heat exchanger 12, and the fifth heat exchanger The heat exchanger 10 is arranged on the conveyor belt 8 of the combine harvest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com