Filter material for a fluid and drainage layer for such a filter material including a filter element

A filter material and filter layer technology, applied in the direction of filter separation, separation methods, chemical instruments and methods, etc., can solve the problems of small anti-pressure alternating load capacity, etc., and achieve the effect of high structural strength and good strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

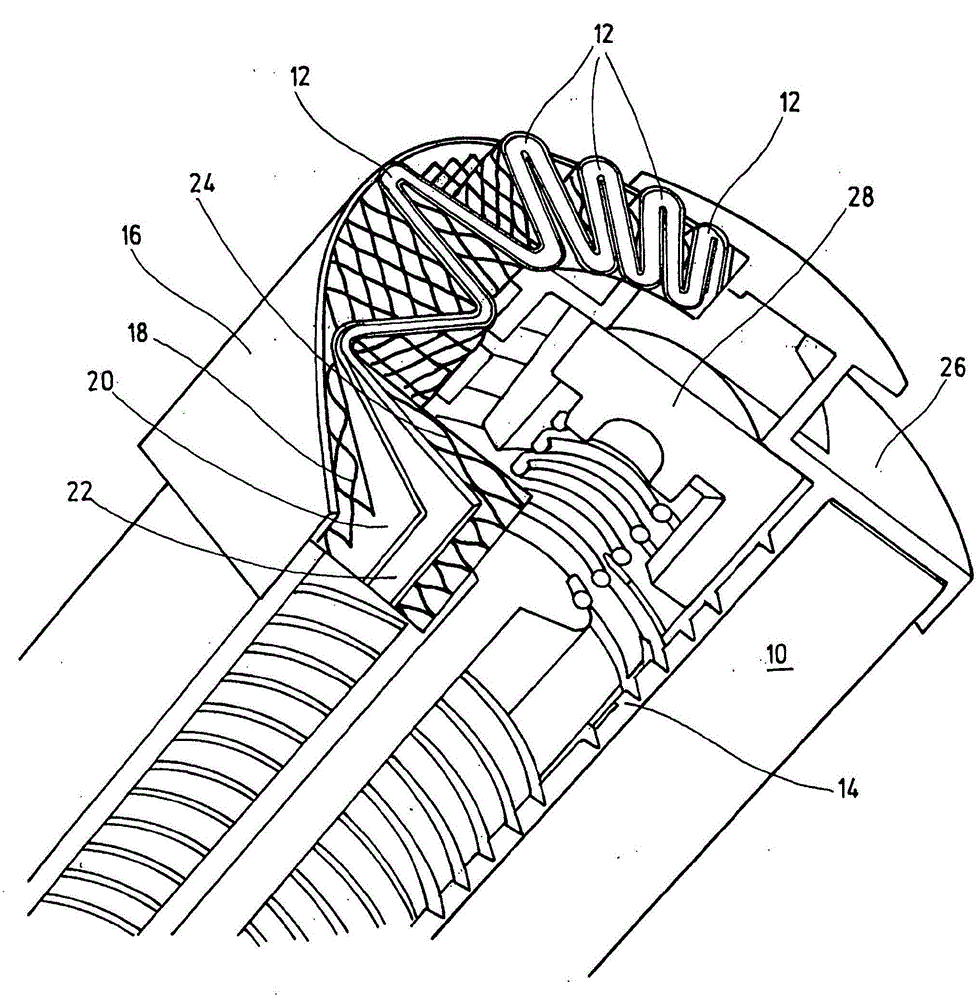

[0020] The filter element shown in part in FIG. 1 as belonging to the prior art has a filter mat 10 as a filter material, the filter mat having a predetermined area size and a predetermined filter characteristic. The filter mat 10 is pleated as shown in FIG. 1, and the filter mat has a plurality of individual filter pleats 12 with a tight packing sequence in the inner, fluid-permeable support tube 14 Extend between and between the outer cylindrical shell 16 which is also fluid permeable. For better illustration, the individual filter pad pleats 12 are shown partially apart from each other, and the single-layer structure of the pleated filter pad 10 can be seen from the partial illustration facing the viewer. The filter pleats 12 constitute a W-shape or a V-shape and are defined between fluid intermediate spaces, which increase in volume on the inflow side directed outward.

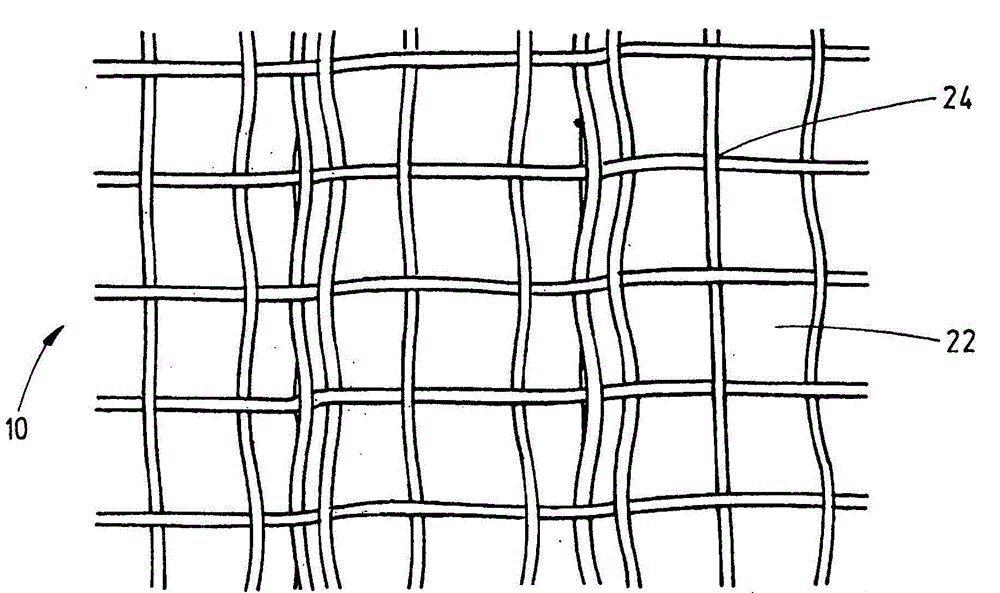

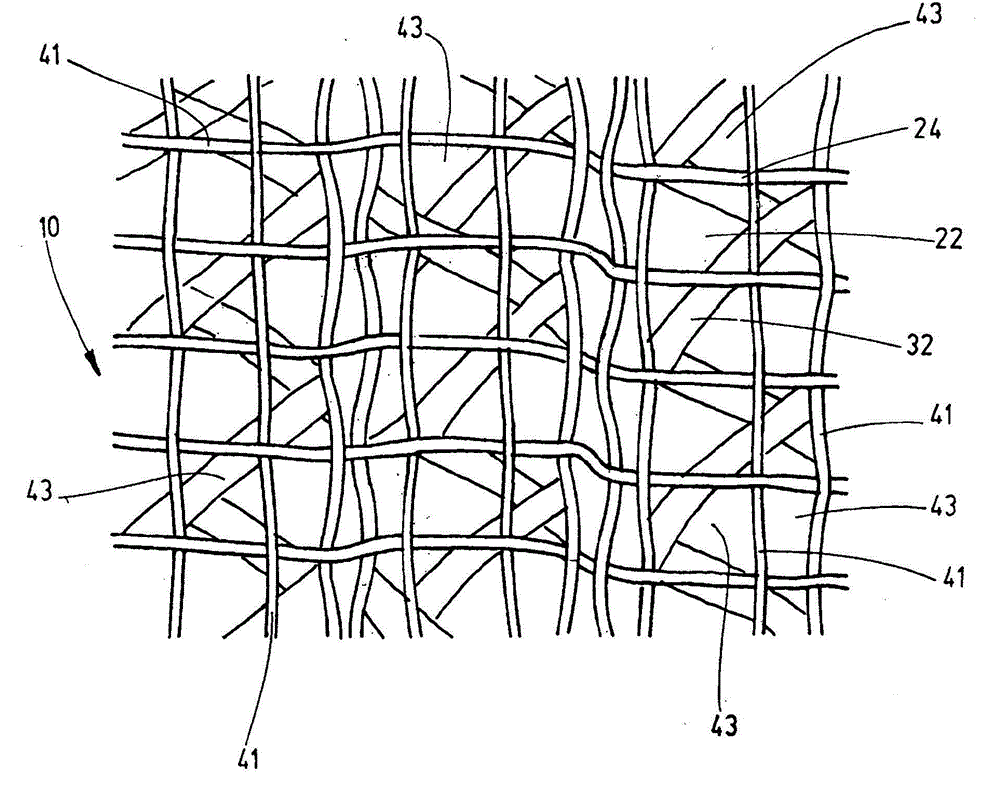

[0021] In the filter element constructed in this way, the filter mat 10 generally includes a first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com