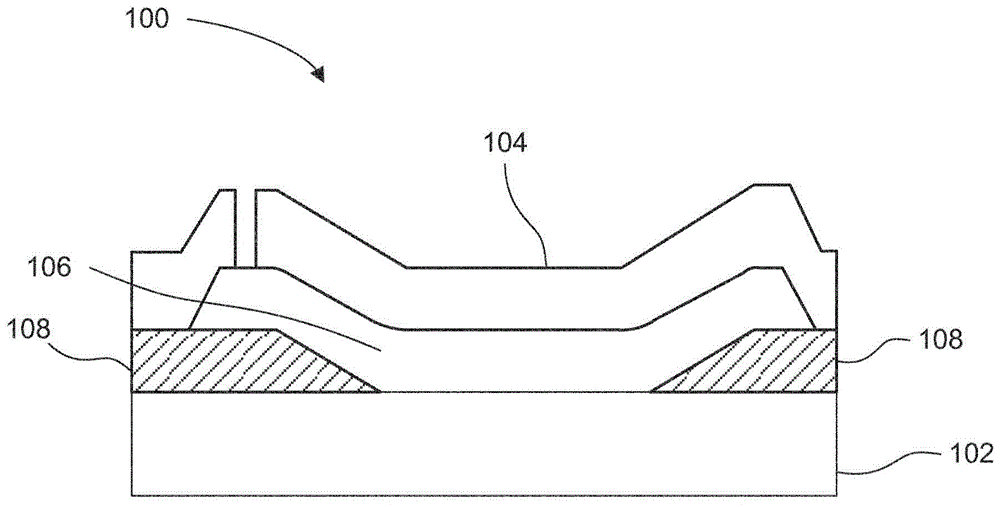

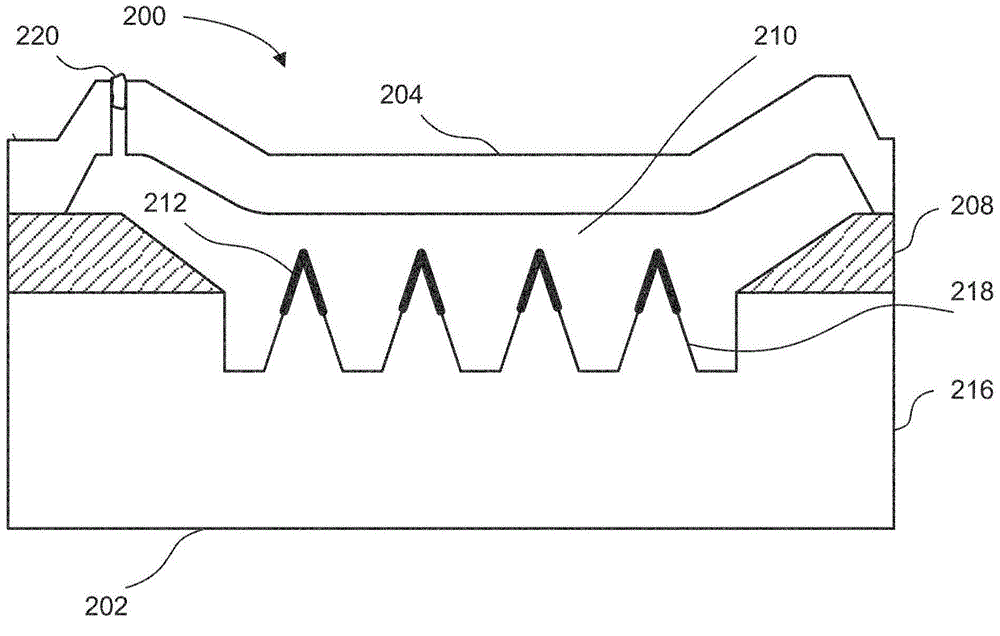

Electrode coating for electron emission devices within cavities

A technology of electron emission and electron emission materials, which is applied in the field of electrode coating of electron emission devices in the cavity, and can solve the problems of time-consuming and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be readily understood that the components of the embodiments mainly described herein and shown in the drawings can be arranged and referred to in many different combinations. Therefore, the following detailed descriptions of various embodiments shown in the drawings are not intended to limit the protection scope of the present invention, but merely represent different embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless explicitly indicated.

[0025]The present invention may embody other specific forms without departing from the spirit or essential characteristics of the invention being invented. The described embodiments are for illustration only and not limitation. The scope of the invention is therefore indicated by the appended claims rather than by the detailed description. All changes in the connotation and range of equivalents fall within the scope of protection claimed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com