Magnetically-driven rotary deicing device of deicing robot for overhead high-voltage transmission lines

A high-voltage transmission line and magnetic drive technology, applied in overhead installation, cable installation, circuit and other directions, can solve the problems of bulky body and low deicing efficiency, achieve low cost, avoid bulky body and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

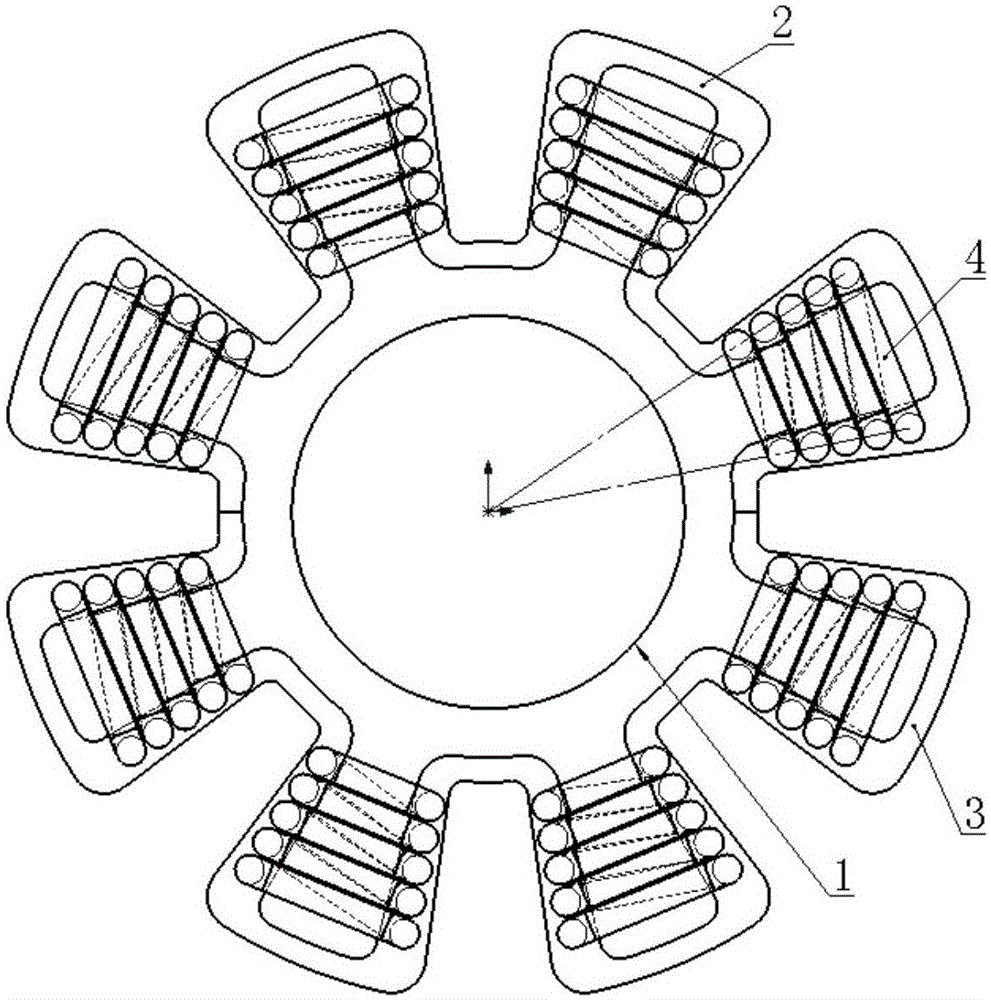

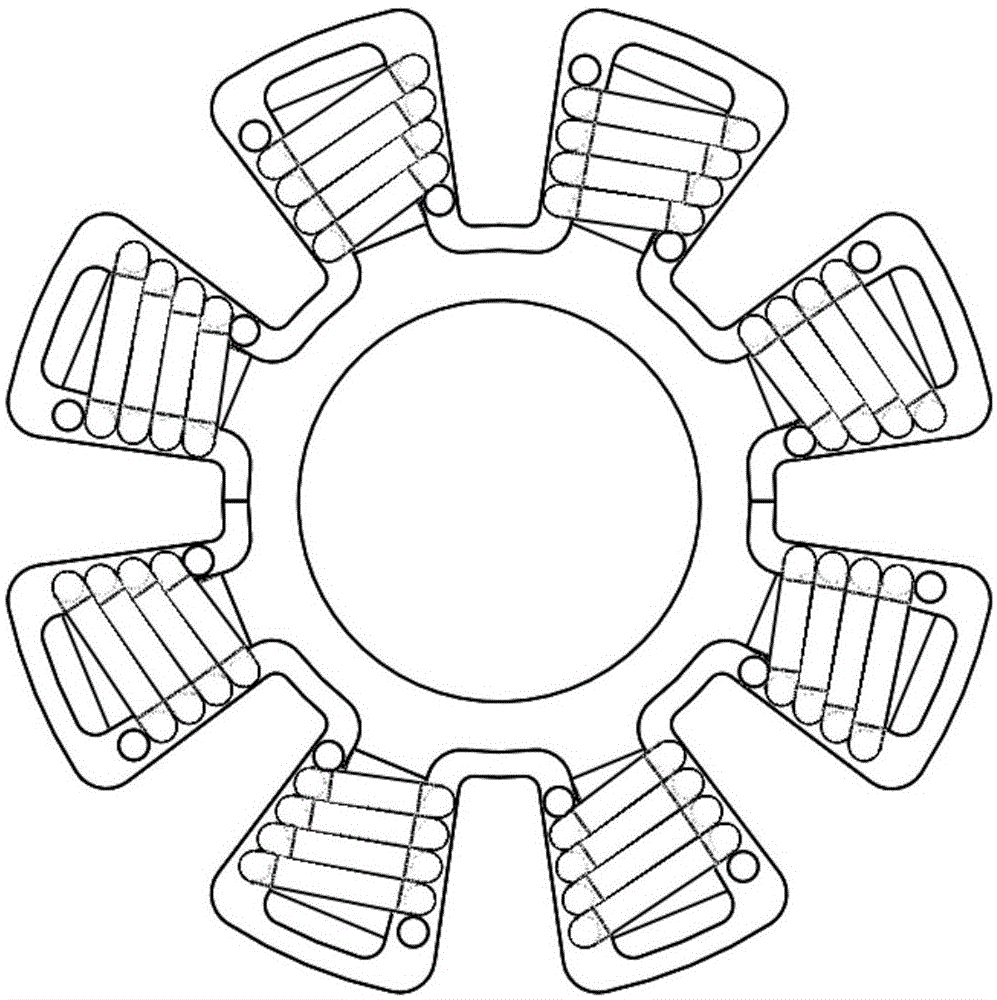

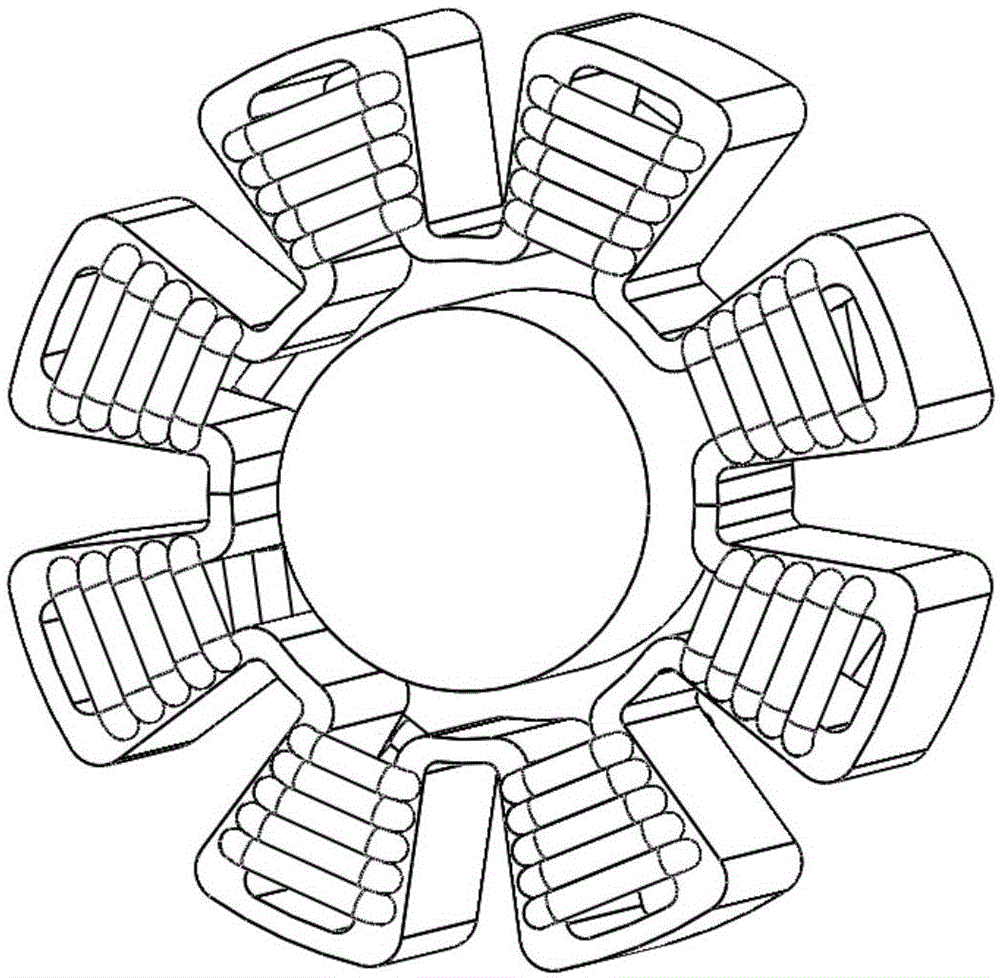

[0027] see figure 1 — Image 6 , the present invention utilizes the ampere force of the magnetic field generated by the high-voltage current to the energized wire to make the deicing device of the robot rotate; it consists of two upper body magnetic cores 2 that have the same structure, can be opened and closed, and can be centrally symmetrical to the high-voltage wire 1 after closing. And the lower body magnetic core 3, the deicing device is composed of the upper body magnetic core 2, the lower body magnetic core 3 and the winding rectangular coil 4.

[0028] The effective long side 401 of the rectangular coil 4 passes through the magnetic core guide holes 301 on the radial sides 302 and 303 of the upper and lower body magnetic cores, and the invalid side of the rectangular coil is placed in weak magnetically permeable materials such as air, etc., and the magnetic force drives The rotary deicing device adopts multi-bosses in the shape of a quincunx. The inner ring 304 and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com