Water-washing control method of assistant washing robot for live water washing of transformer substation

A control method, water flushing technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as the inability to ensure the smooth operation of the robot, the inability to ensure the accurate positioning of the start and end points of the flushing track, and the inability to monitor the position changes of the robot and the insulator in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention is described in detail below in conjunction with accompanying drawing:

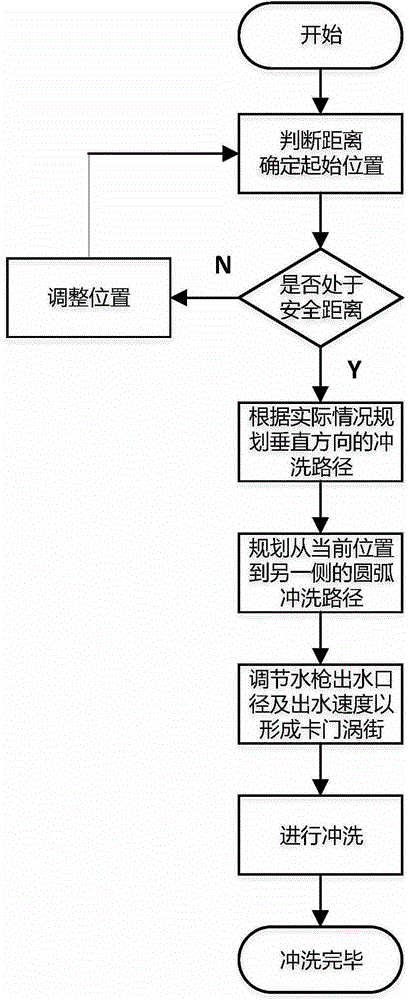

[0064] Such as Figure 1-3 As shown, a substation live water flushing auxiliary flushing robot water flushing control method specifically includes the following steps:

[0065] Step 1: Obtain the relative three-dimensional coordinate value between the current robot and the insulator according to the distance collected by the laser rangefinder installed on the gimbal and the surveillance camera and the monitored image, and judge whether the relative distance between the two is a safe distance. If so, go to the next step , if not, adjust the position of the gimbal until the relative distance is a safe distance; determine the initial state of path planning;

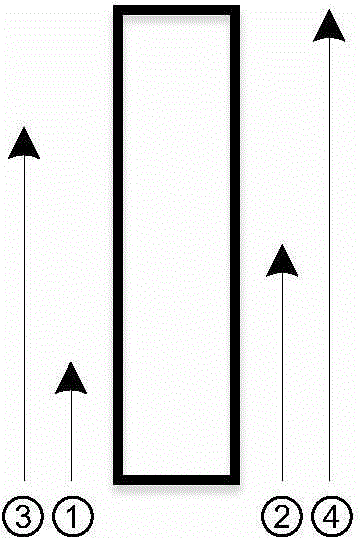

[0066] Step 2: Use the linear interpolation method to realize the automatic flushing of the vertical lifting mechanism for water flushing in the up and down direction of the insulator string;

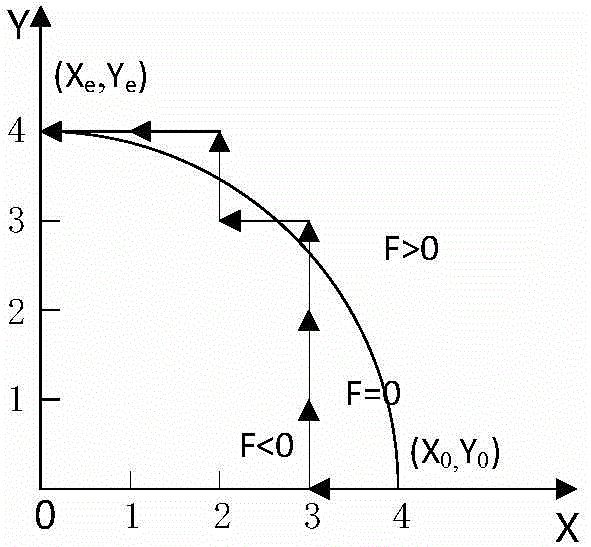

[0067] Step 3: Use the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com