Transitional track planning method for welding robot

A welding robot and trajectory planning technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of not considering the error of the transition section, not considering the transition problem, and difficult to quickly switch between different trajectories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

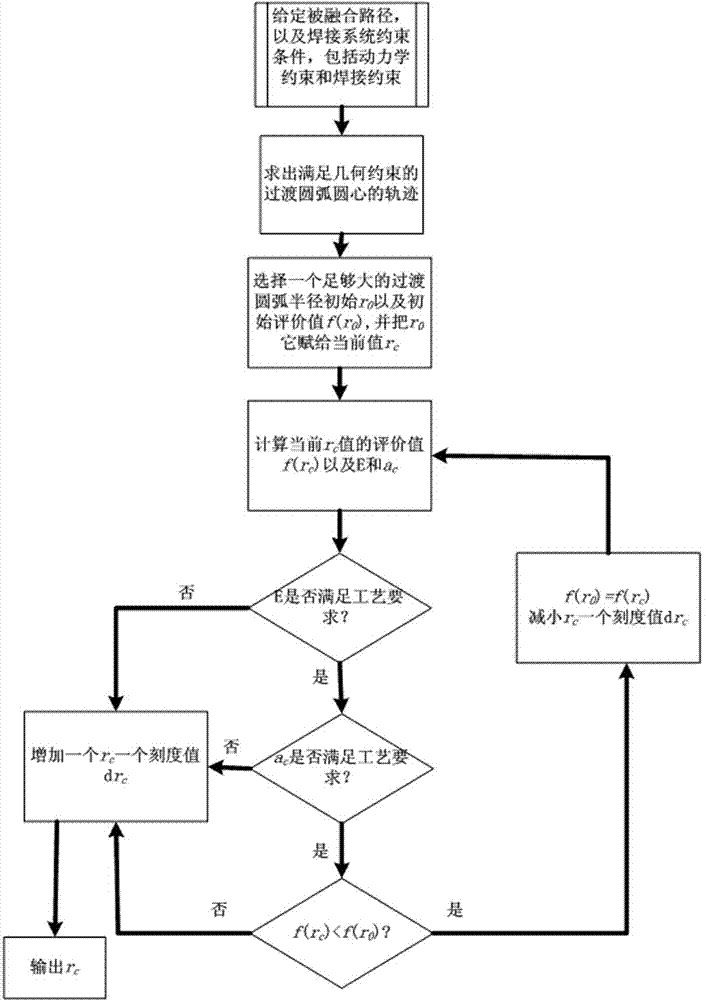

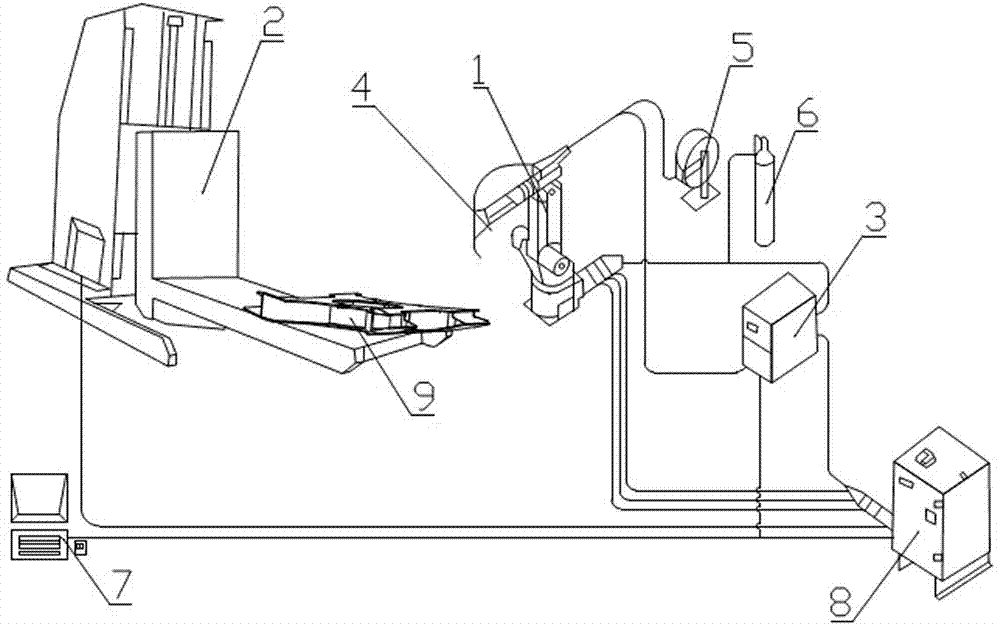

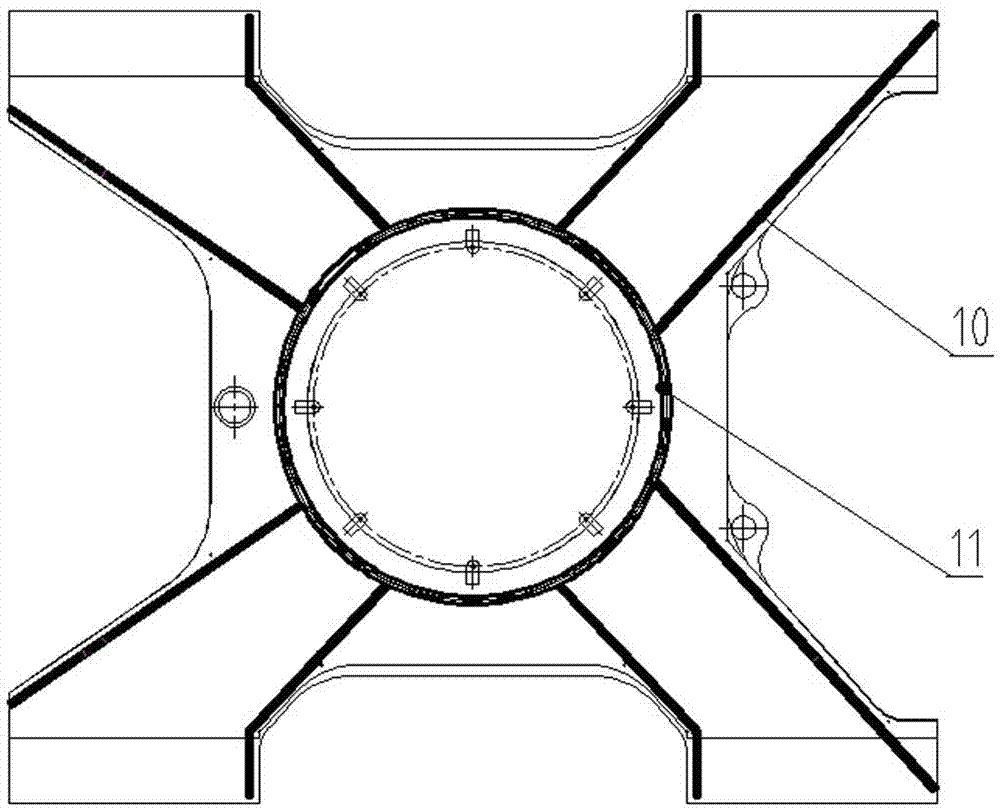

[0045] The present invention will be further described below in conjunction with a 6-DOF robotic arc welding system. The flow chart of welding robot transition trajectory planning is shown in figure 1 As shown, the transition trajectory planning steps are as described above in the content of the invention in this specification. Such as figure 2 As shown, the robot arc welding system consists of an industrial robot 1, a positioner 2, a welding power supply 3, a welding torch 4, a wire feeding mechanism 5, a gas source 6, a control center 7, and a control cabinet 8. Robot 1 is a standard 6-degree-of-freedom industrial robot, and positioner 2 is an L-shaped positioner. Fix the workpiece assembled by spot welding on the working table with T-shaped slots with a pressure plate and T-shaped bolts. The rotation speed can be turned over to the desired position and then lifted to a suitable height to perform welding on the workpiece 9. For the circular welding seam of the rotation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com