Synchronous belt connecting structure

A connection structure and synchronous belt technology, applied in the direction of transmission belts, belt fasteners, belts/chains/gears, etc., can solve the problems of poor moving stability of working parts, increased use and maintenance costs, and easy deformation of plastic materials, etc., to achieve The effect of maintaining smooth movement, simple structure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

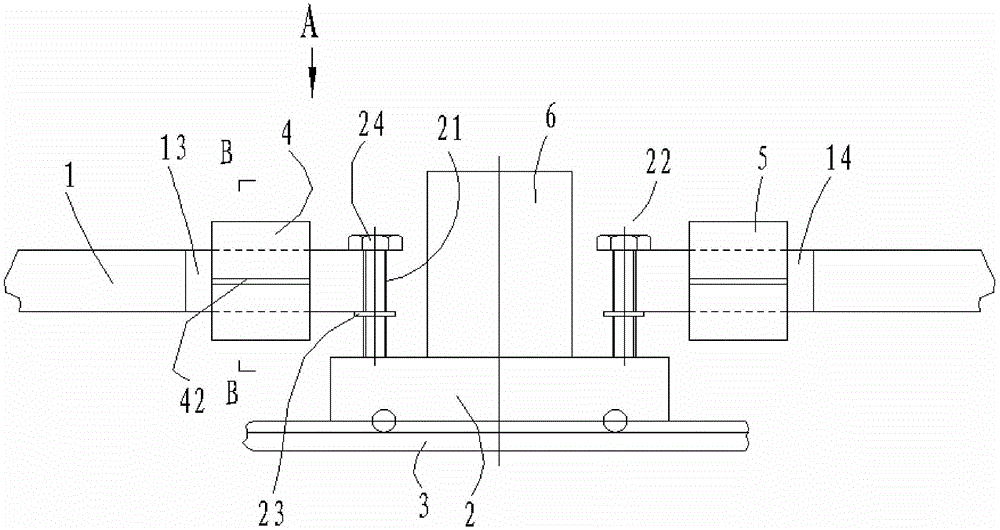

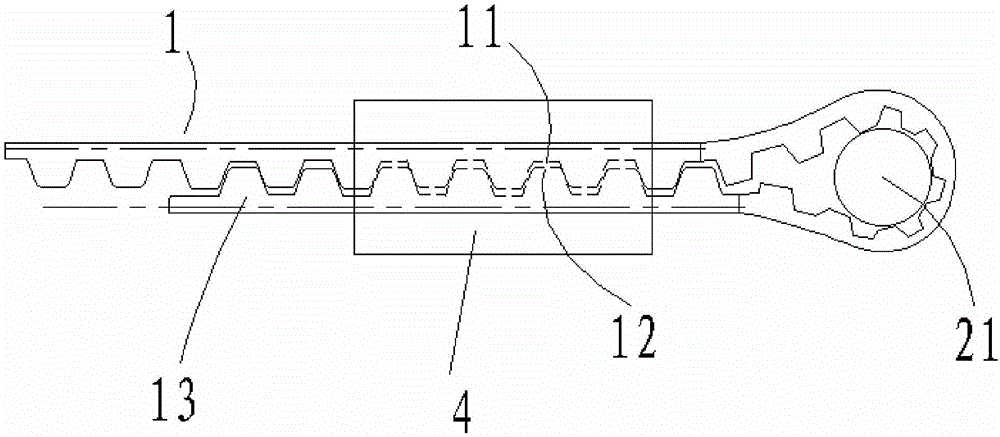

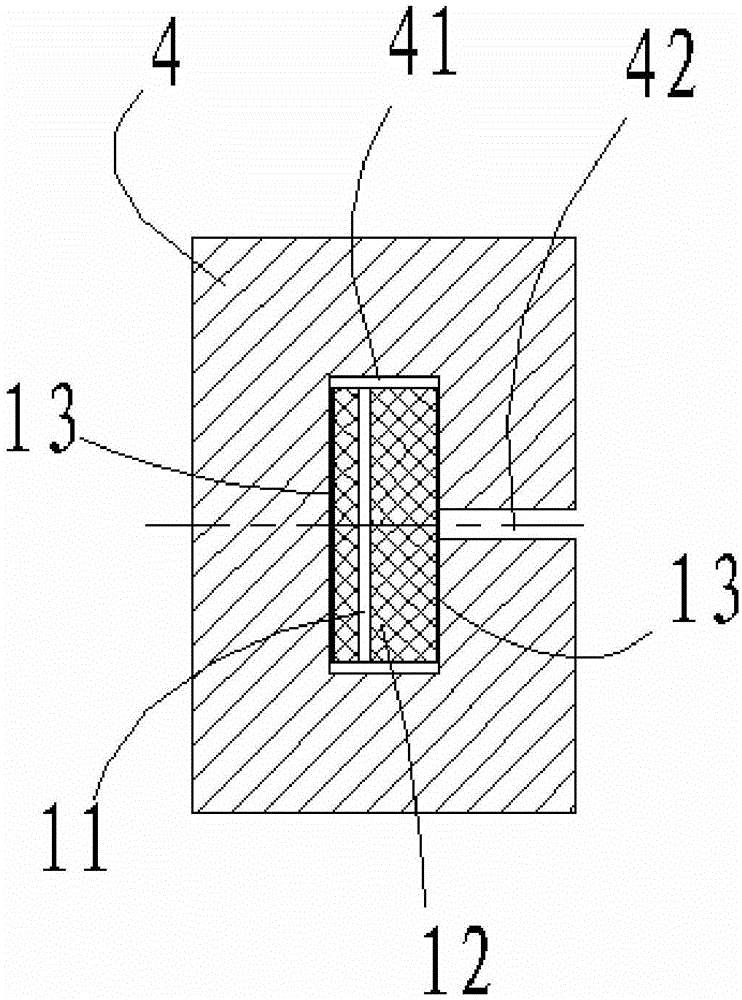

[0021] Such as Figure 1 to Figure 4 As shown, a synchronous belt connection structure includes a synchronous belt 1 and a sliding block 2. The synchronous belt is connected to a driving wheel and a driven wheel respectively, and the driving wheel is connected to a power mechanism such as a motor. The driving wheel drives the driven wheel to rotate through the synchronous belt. The bottom of the slider is matched with the guide rail 3. The left and right ends of the upper part of the slider 2 are respectively provided with a left connecting column 21 and a right connecting column 22. The upper middle part of the slider is provided with a component 6 that needs to be driven and moved by a synchronous belt, such as three In the printing head of a D-ground printer, the middle of the timing belt is discon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com