Precast pile with locking end boards and connecting method of precast pile

A connection method and locking end technology, which can be used in sheet pile walls, buildings, foundation structure engineering, etc., can solve problems such as long time, and achieve the effect of simple operation, easy implementation, and improved vertical pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

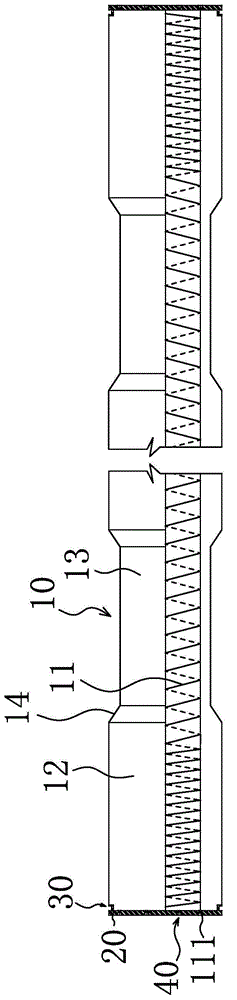

[0040] Such as figure 1 As shown, a prefabricated pile with a locking end plate includes a strip-shaped pile body 10, a steel reinforcement cage 11 is arranged inside the pile body 10, and the two ends of the reinforcement cage 11 are thickened to form a pier head 111, so The pile body 10 described includes alternately arranged large section piles 12 and small section piles 13, the cross section shapes of the large section piles 12 and the small section piles 13 can be circular, square or other shapes, and the large section piles 12 and the small section piles The cross-sectional shapes of the piles 13 may be the same or different.

[0041] A locking end plate 20 is respectively fixed at the two ends of the pile body 10. The end of the pile body 10 can be a large-section pile 12 or a small-section pile 13. The shape of the locking end plate 20 is consistent with that of the pile body 10 ends. same shape as Image 6 As shown, the locking end plate 20 is circular, such as Fi...

Embodiment 2

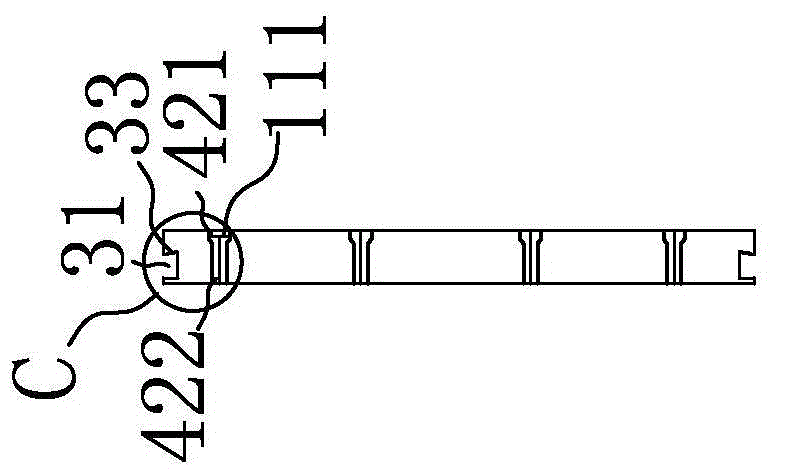

[0053] The structure and connection method of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 2 As shown, the locking groove structure 30 includes a groove 31 provided on the outer wall of the locking end plate 20 . That is, the locking end plate 20 is directly connected to the pile body 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com