Comprehensive processing equipment for dry ginger slices and ginger oil

A technology for comprehensive processing and dried ginger slices, applied in the directions of food preparation, food forming, fat oil/fat production, etc., can solve the problems of ginger slices affecting nutritional value and flavor, difficult to control drying time, and failure to achieve storage purposes. , to achieve the effect of easy implementation, saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

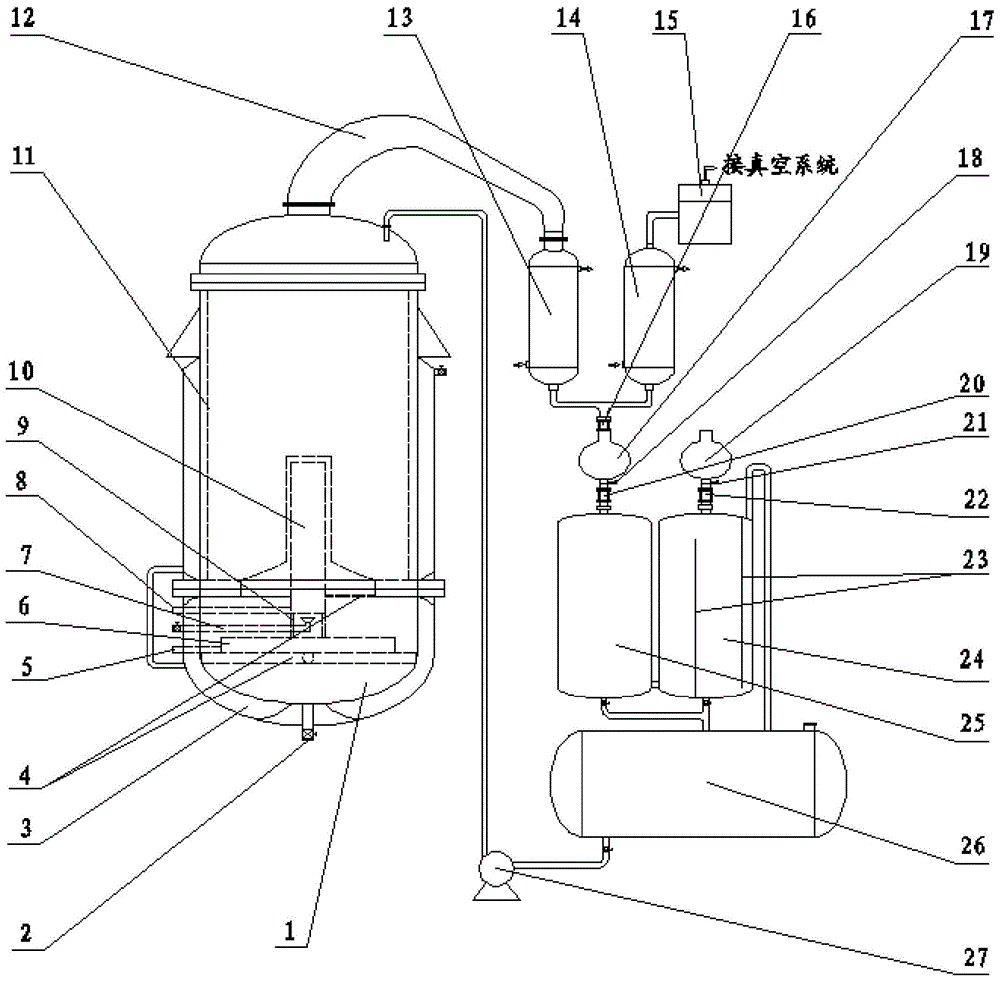

[0035] Such as figure 1 As shown, the present embodiment provides a kind of comprehensive processing equipment of dried ginger slices and ginger oil, which is characterized in that: a kettle body 1, a material basket 11, a steam outlet pipe 12, a condenser A13, a cooler B14, a buffer tank are set 15. Oil collector A17, oil collector B19, oil-water separator A25, oil-water separator B24, liquid sump 26, water pump 27; Steam pipe 12, condenser A13, oil collector A17, oil-water separator A25, oil-water separator B24, sump 26, and water pump 27 are connected in sequence; said cooler B14 is located at the top of oil collector A17; said One end of the buffer tank 15 is connected to the top of the cooler B14, and the other end is connected to the vacuum system; the oil collector B19 is arranged on the top of the oil-water separator B24;

[0036] The kettle body 1 is provided with an upper flange, a lower flange, a sewage outlet 2, a jacket 3, an electric heating plate 6, a steam pip...

Embodiment 2

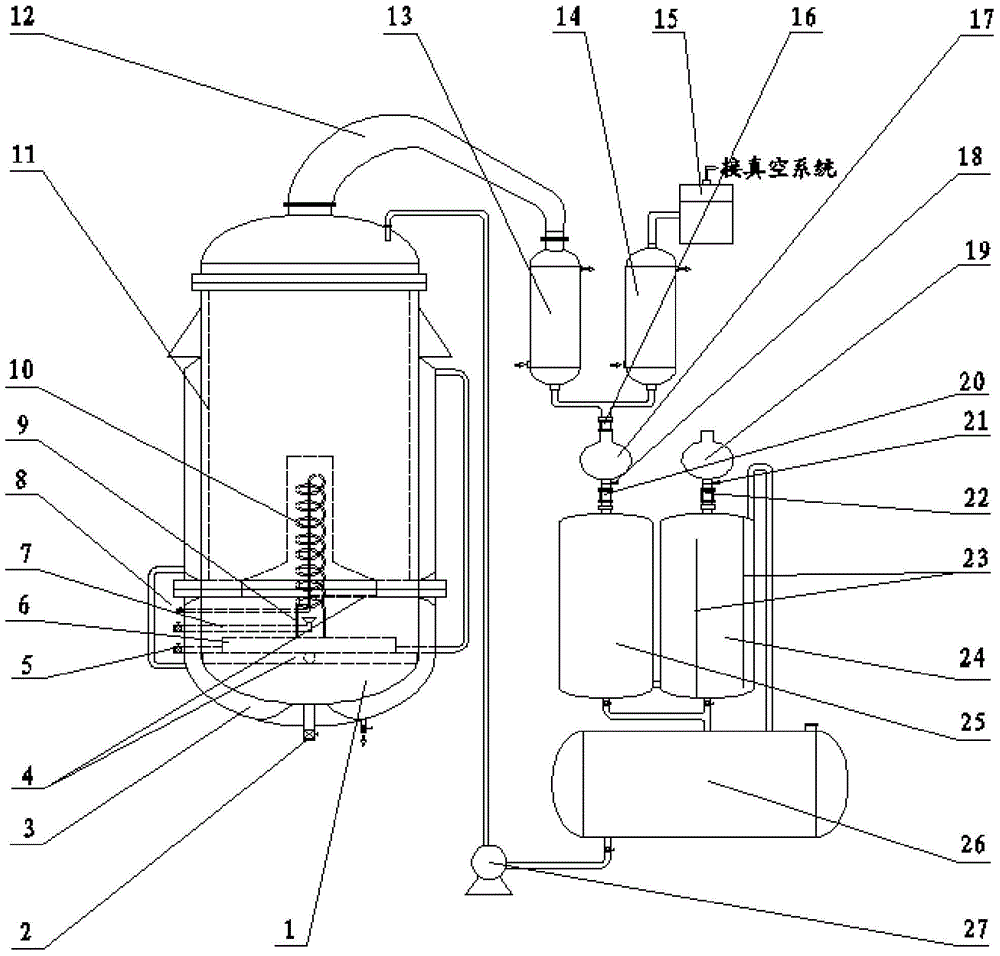

[0055] Such as figure 2 As shown, the present embodiment provides a kind of comprehensive processing equipment of dried ginger slices and ginger oil, which is characterized in that: a kettle body 1, a material basket 11, a steam outlet pipe 12, a condenser A13, a cooler B14, a buffer tank are set 15. Oil collector A17, oil collector B19, oil-water separator A25, oil-water separator B24, liquid sump 26, water pump 27; The steam pipe 12, the condenser 13, the oil collector A17, the oil-water separator A25, the oil-water separator B24, the sump 26, and the water pump 27 are connected in sequence; the cooler B14 is arranged on the top of the oil collector A17; One end of the buffer tank 15 is connected to the top of the cooler B14, and the other end is connected to the vacuum system; the oil collector B19 is arranged on the top of the oil-water separator B24;

[0056] The kettle body 1 is provided with an upper flange, a lower flange, a sewage outlet 2, a jacket 3, a steam pan 6...

Embodiment 3

[0074] The present embodiment provides a kind of comprehensive processing equipment of dried ginger slices and ginger oil, and it is characterized in that: setting includes kettle body 1, material basket 11, steam outlet pipe 12, condenser A13, refrigerator B14, buffer tank 15, collector Oiler A17, oil collector B19, oil-water separator A25, oil-water separator B24, sump 26, water pump 27. The material basket 11 is set in the middle and upper section of the kettle body 1, the kettle body 1, the steam outlet pipe 12, the condenser 13, the oil collector A17, the oil-water separator A25, the oil-water separator B24, the liquid sump 26, and the water pump 27 connected in sequence; the cooler B14 is set on the top of the oil collector A17; one end of the buffer tank 15 is connected to the top of the cooler B14, and the other end is connected to the vacuum system; the oil collector B19 is arranged on the oil-water the top of separator B24;

[0075] The kettle body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com