Twist beam suspension

A technology of torsion beams and suspensions, applied in suspensions, elastic suspensions, transportation and packaging, etc., can solve the problems of cracking at the joints of installation bushes and beams and longitudinal beams, excessive load transfer of the body, and affecting handling performance, etc. Achieve the effect of reducing the risk of structural cracking, improving handling performance, and improving handling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

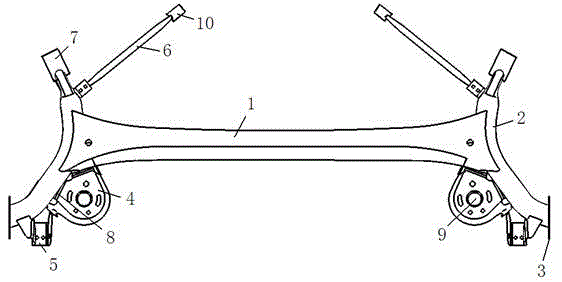

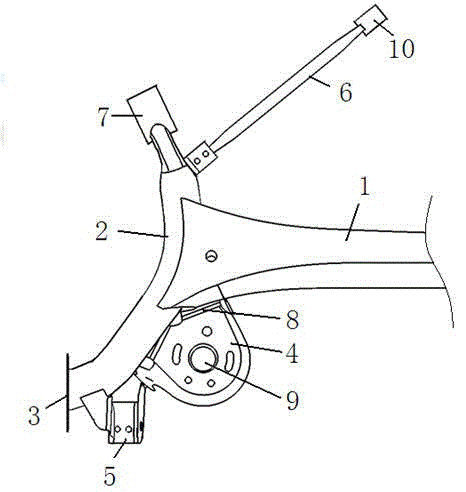

[0019] See attached picture:

[0020] The torsion beam suspension includes a beam 1, and the two ends of the beam 1 are symmetrically provided with a longitudinal beam 2, and the lower end of the longitudinal beam 2 is connected with a longitudinal hub plate 3 for installing wheels; the connection between the longitudinal beam 2 and the beam 1 The lower end is fixedly equipped with a spring seat 4, and a shock absorber mounting bracket 5 is installed on the longitudinal beam 2 on the lower side of the spring seat 4, and the lower side of the outer wall of the spring seat 4 is also welded and fixed with the upper side of the outer wall of the shock absorber bracket 5; A reinforcement bar 6 is installed on the inner sidewall of the upper end of the 2.

[0021] The beam 1 is usually stamped from thick sheet metal, and the thickness is generally 5mm~7mm. The upward or downward opening shape of the beam 1 can be U-shaped or V-shaped, that is, the middle part protrudes outward into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com